Abstract

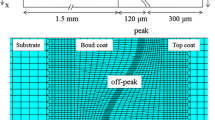

Only a few of the numerous studies on plasma-sprayed thick thermal barrier coatings (TTBCs) have focused on the relationship between the thermal shock resistance of the TTBCs and cracks in the ceramic coating. In this study, three types of TTBCs (a traditional coating, nanostructured coating, and segmentation-cracked coating) with different intrinsic cracks were deposited via atmospheric plasma spraying (APS). To analyze the failure mechanism of these thick coatings, the correlations among the phase composition, microstructure, grain growth behaviors, mechanical properties, and stress distribution were investigated using scanning electron microscope, X-ray diffraction, electron back-scattered diffraction, Raman spectroscope and Vickers hardness tester. The results showed that numerous newly generated vertical cracks in the underlying part of the ceramic topcoat of a TTBC contributed to the release of the accumulated residual stress, thereby improving the thermal shock resistance. The failure mechanism of TTBCs deposited using APS was most likely dominated by residual stresses generated as a result of the thermal expansion mismatch originating from adjacent parts such as the substrate and bond coat, and the bond coat and topcoat. This led to the initiation and propagation of cracks, and finally the peeling of the thick coating.

Similar content being viewed by others

References

D.R. Clarke and C.G. Levi, Materials Design for the Next Generation Thermal Barrier Coatings [J], Annu. Rev. Mater. Res., 2003, 33(1), p 383–417.

N.P. Padture, M. Gell, and E.H. Jordan, Materials Science-Thermal Barrier Coatings for Gas Turbine Engine Applications [J], Science, 2002, 296(5566), p 280–284.

R. Vassen, M.O. Jarligo, T. Steinke et al., Overview on Advanced Thermal Barrier Coatings [J], Surf. Coat. Technol., 2010, 205(4), p 938–942.

I. Gurrappa and R.A. Sambasiva, Thermal Barrier Coatings for Enhanced Efficiency of Gas Turbine Engines [J], Surf. Coat. Technol., 2006, 201, p 3016–3029.

X. Cao, R. Vassen, and D. Stoever, Ceramic Materials for Thermal Barrier Coatings [J], J. Eur. Ceram. Soc., 2004, 24(1), p 1–10.

F. Shao, H. Zhao, X. Zhong et al., Characteristics of Thick Columnar YSZ Coatings Fabricated by Plasma Spray-Physical Vapor Deposition [J], J. Eur. Ceram. Soc., 2018, 38, p 1930–1937.

C. Levi, Emerging Materials and Processes for Thermal Barrier Systems [J], Curr. Opin. Solid State Mater. Sci., 2004, 8(1), p 77–91.

M.A. Helminiak, N.M. Yanar, F.S. Pettit, T.A. Taylor, and G.H. Meier, The Behavior of High Purity, Low Density Air Plasma Sprayed Thermal Barrier Coatings [J], Surf. Coat. Technol., 2009, 204(6–7), p 793–796.

S. Tailor, R. Upadhyaya, S.Y. Manjunath et al., Atmospheric Plasma Sprayed 7%-YSZ thick Thermal Barrier Coatings with Controlled Segmentation Crack Densities and Its Thermal Cycling Behavior [J], Ceram. Int., 2018, 44(3), p 2691–2699.

Z.M. Goudarzi, Z. Valefi, and P. Zamani, Effect of Functionally Graded Structure Design on Durability and Thermal Insulation Capacity of Plasma-Sprayed Thick Thermal Barrier Coating [J], Ceram. Int., 2021, 47(24), p 34361–34379.

K. Wesling, D. Socie, and B. Beardsley, Fatigue of Thick Thermal Barrier Coatings [J], J. Am. Ceram. Soc., 1994, 77(7), p 1863–1868.

H.D. Steffens, Z. Babiak, and M. Gramlich, Some Aspects of Thick Thermal Barrier Coating Lifetime Prolongation [J], J. Therm. Spray Technol., 1998, 8(4), p 517–522.

P. Bengtsson, T. Ericsson, and J. Wigren, Thermal Shock Testing of Burner Cans Coated with a Thick Thermal Barrier Coating [J], J. Therm. Spray Technol., 1998, 7(3), p 340–348.

M. Karger, R. Vassen, and D. Stover, Atmospheric Plasma Sprayed Thermal Barrier Coatings with High Segmentation Crack Densities: Spraying Process, Microstructure and thermal Cycling Behavior [J], Surf. Coat. Technol., 2011, 206(1), p 16–23.

K. Khor, Z. Dong, and Y. Gu, Plasma Sprayed Functionally Graded Thermal Barrier Coatings [J], Mater. Lett., 1999, 38, p 437–444.

A. Scrivani, G. Rizzi, and C. Berndt, Enhanced Thick Thermal Barrier Coatings that Exhibit Varying Porosity [J], Mater. Sci. Eng. A, 2008, 476(1–2), p 1–7.

J. De la Roche, P.A. Gomez, J.M. Alvarado-Orozco et al., Hot Corrosion and Thermal Shock Resistance of Dense-CYSZ/YSZ Bilayer Thermal Barrier Coatings Systems Applied onto Ni-Base Superalloy [J], J. Eur. Ceram. Soc., 2020, 40, p 5692–5703.

S. Tao, J. Yang, W. Li et al., Thermal Stability of Plasma-Sprayed Thick Thermal Barrier Coatings Using Triplex Pro™-200 Torch [J], Coatings, 2020, 10(9), p 1–16.

S. Tao, J. Yang, M. Zhai et al., Thermal Stability of YSZ Thick Thermal Barrier Coatings Deposited by Suspension and Atmospheric Plasma Spraying [J], Curr. Comput.-Aided Drug Des., 2020, 10(11), p 1–13.

K.P. Jonnalagadda, R. Eriksson, K. Yuan et al., A Study of Damage Evolution in High Purity Nano TBCs during Thermal Cycling: A Fracture Mechanics Based Modelling Approach [J], J. Eur. Ceram. Soc., 2017, 37, p 2889–2899.

M. Izadinia, R. Soltani, M.H. Sohi et al., Effect of Segmented Cracks on TGO Growth and Life of Thick Thermal Barrier Coating Under Isothermal Oxidation Conditions [J], Ceram. Int., 2020, 46, p 7475–7481.

Y. Huang, Y. Shen, Y. Zeng et al., EBSD Analysis of Microstructure Changes in YSZ Coatings During Thermal Cycling [J], Ceram. Int., 2021, 47, p 5559–5569.

Z. Wei and H. Cai, Stress States and Crack Behavior in Plasma Sprayed TBCs Based on a Novel Lamellar Structure Model with Real Interface Morphology [J], Ceram. Int., 2019, 45, p 16948–16962.

Z. Wei and H. Cai, An Innovative Model Coupling TGO Growth and Crack Propagation for the Failure Assessment of Lamellar Structured Thermal Barrier Coatings [J], Ceram. Int., 2020, 46, p 2220–2237.

W. Weng, Z. Zheng, and Q. Li, Cracking Evolution of Atmospheric Plasma-Sprayed YSZ Thermal Barrier Coatings Subjected to Isothermal Heat Treatment [J], Surf. Coat. Technol., 2020, 402, p 1–8.

X. Zhang, K. Zhou, H. Chen et al., Properties of Thermal Barrier Coatings made of Different Shapes of ZrO2-7wt.%Y2O3 Powders [J], Rare Metal Mater. Eng., 2015, 44(6), p 1301–1306.

J. Yin, X. Zhang, J. Feng et al., Effect of Powder Composition upon Plasma Spray-Physical Vapor Deposition of 8YSZ Columnar Coating [J], Ceram. Int., 2020, 46, p 15867–15875.

M. Tanaka, M. Hasegawa, A. Dericioglu et al., Measurement of Residual Stress in Air Plasma-Sprayed Y2O3-ZrO2 Thermal Barrier Coating System Using Micro-Raman Spectroscopy [J], Mater. Sci. Eng. A, 2006, 419, p 262–268.

L. Huang, W. Liu, and J. Xu, Effects of various Substrate Materials on Structural and Optical Properties of amorphous Silicon Nitride Thin Films Deposited by Plasma-Enhanced Chemical Vapor Deposition [J], Chin. Opt. Lett., 2020, 18(8), p 083101.

B. Shen, H. **ong, and X. Zhang, Post-Treatment of 351nm SiO2 Antireflective Coatings for High Power Laser Systems Prepared by the Sol-Gel Method [J], Chin. Opt. Lett., 2022, 20(1), p 011601.

T. Pu, W. Liu, and Y. Wang, A Novel Laser Shock Post-Processing Technique on the Laser-Induced Damage Resistance of 1 Omega HfO2/SiO2 Multilayer Coatings [J], High Power Laser Sci. Eng., 2021, 9, p e19.

P. Wang, G. Qi, and Z. Pan, Fabrication of large-Area Uniform Carbon Nanotube Foams as Near-Critical-Density Targets for Laser-Plasma Experiments [J], High Power Laser Sci. Eng., 2021, 9, p e29.

Y. Zhao, L. Wang, J. Yang et al., Thermal Aging Behavior of Axial Suspension Plasma-Sprayed Yttria-Stabilized Zirconia (YSZ) Thermal Barrier Coatings [J], J. Therm. Spray Technol., 2015, 24(3), p 338–347.

A. Keyvani, M. Saremi, and M. Sohi, An Investigation on Oxidation, Hot Corrosion and Mechanical Properties of Plasma Sprayed Conventional and Nanostructured YSZ Coatings [J], Surf. Coat. Technol., 2011, 206(2–3), p 208–216.

K. Amarnath, M. Jenna, LYuan, et al., Nano-Micro-Structured 6%-8% YSZ Thermal Barrier Coatings: A Comprehensive Review of Comparative Performance Analysis [J], Coatings, 2021, 11, p 1474.

L. Yang, Y. Zhou, and C. Lu, Damage Evolution and Rupture Time Prediction in Thermal Barrier Coatings Subjected to Cyclic Heating and Cooling: An Acoustic Emission Method [J], Acta Mater., 2011, 59, p 6519–6529.

W. Mao, Y. Chen, Y. Wang et al., A Multilayer Structure Shear Lag Model Applied in the Tensile Fracture Characteristics of Supersonic Plasma Sprayed Thermal Barrier Coating Systems Based on Digital Image Correlation [J], Surf. Coat. Technol., 2018, 350, p 211–226.

C. Deng, R. Zheng, L. Wang et al., Construction of Three-Dimensional Dynamic Growth TGO (Thermally Grown Oxide) Model and Stress Simulation of 8YSZ Thermal Barrier Coating [J], Ceram. Int., 2022, 48, p 5327–5337.

X. Zhang, K. Zhou, J. Zhang et al., Structure Evolution of 7YSZ Thermal Barrier Coating During Thermal Shock Testing [J], J. Inorg. Mater., 2015, 30(12), p 1261–1266.

P. Carpio, E. Rayon, L. Pawlowski et al., Microstructure and Indentation Mechanical Properties of YSZ Nanostructured Coatings Obtained by Suspension Plasma Spraying [J], Surf. Coat. Technol., 2013, 220, p 237–243.

M. Zhai, D. Li, Y. Zhao et al., Comparative Study on Thermal Shock Behavior of Thick Thermal Barrier Coatings Fabricated with Nano-Based YSZ Suspension and Agglomerated Particles [J], Ceram. Int., 2016, 153, p 12172–12179.

Y. Zhao, D. Li, X. Zhong et al., Thermal Shock Behaviors of YSZ Thick Thermal Barrier Coatings Fabricated by Suspension and Atmospheric Plasma Spraying [J], Surf. Coat. Technol., 2014, 249, p 48–55.

J. Yang, L. Wang, D. Li et al., Stress Analysis and Failure Mechanisms of Plasma-Sprayed Thermal Barrier Coatings [J], J. Therm. Spray Technol., 2017, 26(5), p 809–901.

J. Kwon, J. Kim, S. Lee et al., Microstructural Evolution and Residual Stresses of Air-Plasma Sprayed Thermal Barrier Coatings Under Thermal Exposure [J], Surf. Rev. Lett., 2010, 17(3), p 337–343.

X. Zhao and P. **ao, Residual Stresses in Thermal Barrier Coatings Measured by Photoluminescence Piezo-Spectroscopy and Indentation Technology [J], Surf. Coat. Technol., 2006, 201, p 1124–1131.

H. Samadi and T. Coyle, Modeling the Build-up of Interface Stresses in Multilayer Thick Barrier Coatings [J], J. Therm. Spray Technol., 2009, 18(5–6), p 996–1003.

J. Krogstad, M. Lepple, Y. Gao et al., Effect of Yttria Content on the Zirconia Unit Cell Parameters [J], J. Am. Ceram. Soc., 2011, 94, p 4548–4555.

M. Gizynski, X. Chen, N. Dusautoy et al., Comparative Study of the Failure Mechanism of Atmospheric and Suspension Plasma Sprayed Thermal Barrier Coatings [J], Surf. Coat. Technol., 2019, 370, p 163–176.

M. Rajabi, M.R. Aboutalebi, S.H. Seyedein et al., Simulation of Residual Stress in Thick Thermal Barrier Coating (TTBC) During Thermal Shock: A Response Surface-Finite Element Modeling [J], Ceram. Int., 2022, 48(4), p 5299–5311.

J. Yang, H. Zhao, X. Zhong et al., Evolution of Residual Stresses in PS-PVD Thermal Barrier Coatings on Thermal Cycling [J], J. Therm. Spray Technol., 2018, 27(6), p 914–923.

L. Wang, Y. Wang, X. Sun et al., Microstructure and Surface Residual Stress of Plasma Sprayed Nanostructured and Conventional ZrO2-8wt.% Thermal Barrier Coatings [J], Surf. Interface Anal., 2011, 43(5), p 869–880.

Acknowledgments

This research was funded by the National Science and Technology Major Project (No. 2017-VI-0010-0082), the National Natural Science Foundation of China (NSFC) (No. 51701235), Science and Technology Innovation of Shanghai (No. 18511108702), the Natural Science Foundation of Shanghai (21ZR1472800), and Basic Research of the Ministry of Science and Technology of the Chinese Academy of Sciences (CXJJ-21S029).

Author information

Authors and Affiliations

Contributions

ST and JY contributed to conceptualization; ST, JY, FS, HZ, XZ, YZ, JS, JN, and ST contributed to data curation and formal analysis; ST contributed to writing—original draft preparation; JY and ST contributed to writing—review and editing. All the authors have read and agreed to the published version of the manuscript.

Corresponding authors

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Tao, S., Yang, J., Shao, F. et al. Effect of Cracks on Thermal Shock Behavior of Plasma-Sprayed Thick Thermal Barrier Coatings. J. of Materi Eng and Perform 32, 4998–5014 (2023). https://doi.org/10.1007/s11665-022-07482-0

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-022-07482-0