Abstract

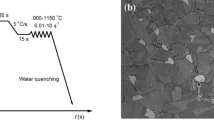

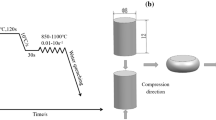

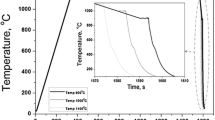

Hot deformation behavior of a high Al ferritic low-density steel (Fe-11wt.%Al-10wt.%Mn-1wt.%C) was investigated using hot compression tests up to a true strain of 0.69 at strain rates of 0.001-0.1 s−1 in a Gleeble thermomechanical simulator. When deformed at 900 °C the steel is ferritic and mostly dynamic recovery was observed. The samples hot compressed at 1000 and 1100 °C exhibited a dual phase microstructure (ferrite + austenite) and an appreciable amount of dynamic recrystallization (DRX) was observed in both the phases. There was a significant refinement in microstructure when the alloy was deformed in the intercritical region. The activation energy of dynamic recrystallization for the alloy was calculated to be 272.08 kJ mol−1. The ferrite phase exhibited continuous dynamic recrystallization (CDRX) whereas the austenite exhibited discontinuous dynamic recrystallization (DDRX). A constitutive equation for predicting the flow stress values corresponding to a particular strain during hot deformation was derived using the basic Zener-Hollomon equation. Average absolute relative error (AARE) value of 6.2% and correlation coefficient (R) value of 0.97 were obtained indicating a high accuracy of the formulated constitutive relation. The DRX fractions were calculated from Johnson–Mehl–Avrami–Kolmogorov (JMAK) equation as well as grain orientation spread (GOS ≤ 1°) criterion. Fractions obtained for different deformation conditions by the two methods were compared.

Similar content being viewed by others

References

S. Chen, R. Rana, A. Haldar, and R.K. Ray, Current State of Fe-Mn-Al-C Low Density Steels, Prog. Mater. Sci., 2017, 89, p 345–391. https://doi.org/10.1016/j.pmatsci.2017.05.002

O.A. Zambrano, A General Perspective of Fe-Mn-Al-C Steels, J. Mater. Sci., 2018, 53(20), p 14003–14062. https://doi.org/10.1007/s10853-018-2551-6

C. Castan, F. Montheillet, and A. Perlade, Dynamic Recrystallization Mechanisms of an Fe-8% Al Low Density Steel under Hot Rolling Conditions, Scr. Mater., 2013, 68(6), p 360–364. https://doi.org/10.1016/j.scriptamat.2012.07.037

X. Xu, X. Wang, J. Li, Z. Yan, D. Liu, Q. Liu, C. Shang, J. Fu, and P. Shen, Hot Workability Characteristics of Low-Density Fe-4Al-1Ni Ferritic Steel, Mater. Sci. Eng., 2020, 799, p 140257. https://doi.org/10.1016/j.msea.2020.140257

R.S. Kumar, U. Prakash, and S.K. Nath, Workability Studies on High Al Ferritic Fe-Al-C Alloys, JOM, 2014, 66(9), p 1800–1808. https://doi.org/10.1007/s11837-014-1061-5

P. Rawat, U. Prakash, and V.V.S. Prasad, Phase Transformation and Hot Working Studies on High-Al Fe-Al-Mn-C Ferritic Low-Density Steels, J. Mater. Eng. Perform., 2021, 30(8), p 6297–6308. https://doi.org/10.1007/s11665-021-05857-3

D. Liu, H. Ding, M. Cai, and D. Han, Hot Deformation Behavior and Processing Map of a Fe-11Mn-10Al-0.9C Duplex Low-Density Steel Susceptible to κ-Carbides, J. Mater. Eng. Perform., 2019, 28(8), p 5116–5126. https://doi.org/10.1007/s11665-019-04200-1

S.Y. Han, S.Y. Shin, S. Lee, N.J. Kim, J.H. Kwak, and K.G. Chin, Effect of Carbon Content on Cracking Phenomenon Occurring during Cold Rolling of Three Light-Weight Steel Plates, Metall. Mater. Trans. A Phys. Metall. Mater. Sci., 2011, 42(1), p 138–146.

D. Liu, H. Ding, M. Cai, and D. Han, Mechanical Behaviors of a Lower-Mn-Added Fe-11Mn-10Al-1.25C Lightweight Steel with Distinguished Microstructural Features, Mater. Lett., 2019, 242, p 131–134. https://doi.org/10.1016/j.matlet.2019.01.115

Y.L.R. Song and E.W.F. Yang, Hot Deformation and Dynamic Recrystallization Behavior of Austenite-Based Low-Density Fe-Mn-Al-C Steel, Acta Metall. Sin. English Lett., 2016, 29(5), p 441–449. https://doi.org/10.1007/s40195-016-0406-1

C.M. Sellars and W.J. McTegart, On the Mechanism of Hot Deformation, Acta Metall., 1966, 14(9), p 1136–1138. https://doi.org/10.1016/0001-6160(66)90207-0

H. Khatami-Hamedani, A. Zarei-Hanzaki, H.R. Abedi, A.S. Anoushe, and L.P. Karjalainen, Dynamic Restoration of the Ferrite and Austenite Phases during Hot Compressive Deformation of a Lean Duplex Stainless Steel, Mater. Sci. Eng. A, 2020, 788, p 139400. https://doi.org/10.1016/j.msea.2020.139400

S. Kumar, A. Karmakar, and S.K. Nath, Comparative Assessment on the Hot Deformation Behaviour of 9Cr-1Mo Steel with 1Cr-1Mo Steel, Met. Mater. Int., 2021, 27(10), p 3875–3890. https://doi.org/10.1007/s12540-020-00826-2

H. Gwon, S. Shin, J. Jeon, T. Song, S. Kim, and B.C. De Cooman, Hot Deformation Behavior of V Micro-Alloyed TWIP Steel During Hot Compression, Met. Mater. Int., 2019, 25(3), p 594–605. https://doi.org/10.1007/s12540-018-00224-9

D. Samantaray, S. Mandal, and A.K. Bhaduri, Constitutive Analysis to Predict High-Temperature Flow Stress in Modified 9Cr-1Mo (P91) Steel, Mater. Des., 2010, 31(2), p 981–984. https://doi.org/10.1016/j.matdes.2009.08.012

S. Mandal, V. Rakesh, P.V. Sivaprasad, S. Venugopal, and K.V. Kasiviswanathan, Constitutive Equations to Predict High Temperature Flow Stress in a Ti-Modified Austenitic Stainless Steel, Mater. Sci. Eng. A, 2009, 500(1–2), p 114–121. https://doi.org/10.1016/j.msea.2008.09.019

M. Chegini, M.R. Aboutalebi, S.H. Seyedein, G.R. Ebrahimi, and M. Jahazi, Study on Hot Deformation Behavior of AISI 414 Martensitic Stainless Steel Using 3D Processing Map, J. Manuf. Process., 2020, 56, p 916–927. https://doi.org/10.1016/j.jmapro.2020.05.008

A. Oudin, P.D. Hodgson, and M.R. Barnett, EBSD Analysis of a Ti-IF Steel Subjected to Hot Torsion in the Ferritic Region, Mater. Sci. Eng. A, 2008, 486(1–2), p 72–79. https://doi.org/10.1016/j.msea.2007.09.045

P. Cizek, The Microstructure Evolution and Softening Processes during High-Temperature Deformation of a 21Cr-10Ni-3Mo Duplex Stainless Steel, Acta Mater., 2016, 106, p 129–143. https://doi.org/10.1016/j.actamat.2016.01.012

O.A. Zambrano, J. Valdés, Y. Aguilar, J.J. Coronado, S.A. Rodríguez, and R.E. Logé, Materials Science & Engineering A Hot Deformation of a Fe-Mn-Al-C Steel Susceptible of κ-Carbide Precipitation, Mater. Sci. Eng. A, 2017, 689, p 269–285. https://doi.org/10.1016/j.msea.2017.02.060

X. Wang, D. Wang, J. **, and J. Li, Effects of Strain Rates and Twins Evolution on Dynamic Recrystallization Mechanisms of Austenite Stainless Steel, Mater. Sci. Eng. A, 2019, 761, p 138044. https://doi.org/10.1016/j.msea.2019.138044

O.A. Zambrano, Stacking Fault Energy Maps of Fe-Mn-Al-C-Si Steels: Effect of Temperature, Grain Size, and Variations in Compositions, J. Eng. Mater. Technol., 2016, 138(4), p 1–9. https://doi.org/10.1115/1.4033632

M.S. Ghazani, B. Eghbali, and G. Ebrahimi, Kinetics and Critical Conditions for Initiation of Dynamic Recrystallization during Hot Compression Deformation of AISI 321 Austenitic Stainless Steel, Met. Mater. Int., 2017, 23(5), p 964–973. https://doi.org/10.1007/s12540-017-6391-8

C. Zhang, L. Zhang, W. Shen, C. Liu, Y. **a, and R. Li, Study on Constitutive Modeling and Processing Maps for Hot Deformation of Medium Carbon Cr-Ni-Mo Alloyed Steel, Mater. Des., 2016, 90, p 804–814. https://doi.org/10.1016/j.matdes.2015.11.036

F. Chen, X. Zhao, J. Ren, H. Chen, and X. Zhang, Physically-Based Constitutive Modelling of As-Cast CL70 Steel for Hot Deformation, Met. Mater. Int., 2021, 27(6), p 1728–1738. https://doi.org/10.1007/s12540-019-00541-7

E.I. Poliak and J.J. Jonas, Initiation of Dynamic Recrystallization in Constant Strain Rate Hot Deformation, ISIJ Int., 2003, 43(5), p 684–691. https://doi.org/10.2355/isi**ternational.43.684

J.J. Jonas, X. Quelennec, L. Jiang, and É. Martin, The Avrami Kinetics of Dynamic Recrystallization, Acta Mater., 2009, 57(9), p 2748–2756. https://doi.org/10.1016/j.actamat.2009.02.033

Y.H. Mozumder, K. Arun Babu, R. Saha, and S. Mandal, Flow Characteristics and Hot Workability Studies of a Ni-Containing Fe-Mn-Al-C Lightweight Duplex Steel, Mater. Charact., 2018, 146, p 1–14. https://doi.org/10.1016/j.matchar.2018.09.036

H. Mirzadeh, J.M. Cabrera, A. Najafizadeh, and P.R. Calvillo, EBSD Study of a Hot Deformed Austenitic Stainless Steel, Mater. Sci. Eng. A., 2012, 538, p 236–245. https://doi.org/10.1016/j.msea.2012.01.037

K.A. Babu, S. Mandal, C.N. Athreya, B. Shakthipriya, and V.S. Sarma, Hot Deformation Characteristics and Processing Map of a Phosphorous Modified Super Austenitic Stainless Steel, Mater. Des., 2017, 115, p 262–275. https://doi.org/10.1016/j.matdes.2016.11.054

A. Sarkar, S. Sanyal, T.K. Bandyopadhyay, and S. Mandal, Influence of Annealing Parameters on Phase Evolution and Recrystallization Kinetics of a Mn-Al-Si Alloyed Duplex Steel, Mater. Charact., 2017, 134, p 213–224. https://doi.org/10.1016/j.matchar.2017.10.023

A. Sarkar, S. Sanyal, T.K. Bandyopadhyay, and S. Mandal, Implications of Microstructure, Taylor Factor Distribution and Texture on Tensile Properties in a Ti-Added Fe-Mn-Al-Si-C Steel, Mater. Sci. Eng. A, 2019, 767, p 138402. https://doi.org/10.1016/j.msea.2019.138402

Acknowledgments

The work was supported by ER&IPR, DRDO, New Delhi.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Rawat, P., Prakash, U. & Satya Prasad, V.V. Studies on Hot Deformation Behavior and Dynamic Recrystallization in a High Al Ferritic Low-Density Steel. J. of Materi Eng and Perform 32, 4541–4554 (2023). https://doi.org/10.1007/s11665-022-07428-6

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-022-07428-6