Abstract

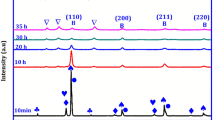

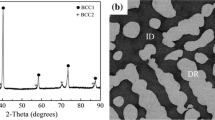

In the present work, a refractory high-entropy alloy of the composition MoNbTaW has been synthesized by vacuum arc melting starting with elemental powders. The alloy formed as a solid solution with the body-centered cubic crystal structure. Thermomechanical processing was performed, and the sizeable compressive strain induced during this step aided in removing the dendritic microstructure in the as-cast sample. Further homogenization at 1400 °C for 20 h showed partial recrystallization (as studied by Electron Backscatter Diffraction). The sample subjected to thermomechanical processing followed by homogenization exhibited higher hardness than similar refractory high-entropy alloys in the literature. Detailed estimations on probable strengthening mechanisms in this system under various processing conditions suggest that solid solution strengthening is the dominant mechanism. The obtained Tabor factor for each processing condition of this alloy is in the range of 2.6–2.9, and these numbers are in close agreement with those observed for various metallic materials, including high-entropy alloys.

Similar content being viewed by others

References

E.P. George, D. Raabe and R.O. Ritchie, High-Entropy Alloys, Nat. Rev. Mater., 2019, 4(8), p 515–534.

J. Chen, X. Zhou, W. Wang, B. Liu, Y. Lv, W. Yang, D. Xu and Y. Liu, A Review on Fundamental of High Entropy Alloys with Promising High-Temperature Properties, J. Alloys Compd., 2018, 760, p 15–30.

D.B. Miracle, O.N. Senkov, A Critical Review of High Entropy Alloys and Related Concepts. Acta Mater. 1–64 (2016).

O.N. Senkov, G.B. Wilks, D.B. Miracle, C.P. Chuang and P.K. Liaw, Refractory High- Entropy Alloys, Intermetallics, 2010, 18(9), p 1758–1765.

Z.D. Han, H.W. Luan, X. Liu, N. Chen, X.Y. Li, Y. Shao and K.F. Yao, Microstructures and Mechanical Properties of TixNbMoTaW Refractory High-Entropy Alloys, Mater. Sci. Eng. A, 2018, 712, p 380–385.

X.J. Gao, L. Wang, N.N. Guo, L.S. Luo, G.M. Zhu, C.C. Shi, Y.Q. Su and J.J. Guo, Microstructure Characteristics and Mechanical Properties of Hf05Mo05NbTiZr Refractory High Entropy Alloy with Cr Addition, Int. J. Refract. Met. Hard Mater., 2021, 95, p 105405.

O.N. Senkov, G.B. Wilks, J.M. Scott and D.B. Miracle, Mechanical Properties of Nb25Mo25Ta25W25 and V20Nb20Mo20Ta20W20 Refractory High Entropy Alloys, Intermetallics, 2011, 19(5), p 698–706.

Y. Zou, S. Maiti, W. Steurer and R. Spolenak, Size-Dependent Plasticity in an Nb25Mo25Ta25W25 Refractory High-Entropy Alloy, Acta Mater., 2014, 65, p 85–97.

Y. Zou, P. Okle, H. Yu, T. Sumigawa, T. Kitamura, S. Maiti, W. Steurer and R. Spolenak, Fracture Properties of a Refractory High Entropy Alloy: In Situ Micro-Cantilever and Atom Probe Tomography Studies, Scr. Marter., 2017, 128, p 95–99.

F.U. Jian-xin, C.A.O. Cheng-ming, T.O.N.G. Wei and P.E.N.G. Liang-ming, Effect of Thermomechanical Processing on Microstructure and Mechanical Properties of CoCrFeNiMn High Entropy Alloy, Trans. Nonferrous Met. Soc. China, 2018, 28, p 931–938.

P. Mukhopadhyay, Structural Metallurgy of Refractory Metals, Miner. Proc. Extr. Metall. Rev., 2018, 22(1), p 121–138.

K.A. Gschneidner et al., Binary Alloy Phase Diagrams, ASM, Metals Park (OH), 1986.

D.A. Porter, K.E. Easterling and M.Y. Sherif, Phase Transformations in Metals and Alloys, 3rd ed. CRC Press, US, 1992, p 189–220

W.L. Zhao, D.P. Wang, H.D. Wang, S.C. Ma, Y.Y. Wang and Y.Q. Zhang, Grain Boundary Segregation and Precipitation During the Plastic Deformation of 30Cr2Ni4MoV Steel, Mater. Trans., 2018, 59(5), p 822–828.

J.L. Zhang, C.C. Tasan, M.J. Lai, D. Yan and D. Raabe, Partial Recrystallization of Gum Metal to Achieve Enhanced Strength and Ductility, Acta Mater., 2017, 135, p 400–410.

S. Raveendra, S. Mishra, K.V. Mani Krishna, H. Weiland and I. Samajdar, Patterns of Recrystallization in Warm- and Hot-Deformed AA6022, Metall. Mater. Trans. A, 2008, 39, p 2760–2771.

B. Kang, J. Lee, H.J. Ryu and S.H. Hong, Ultra-High Strength WNbMoTaV High-Entropy Alloys with Fine Grain Structure Fabricated by Powder Metallurgical Process, Mater. Sci. Eng. A, 2018, 712, p 616–624.

G. Ramya Sree, P. Sai Karthik, K. Bhanu Sankara Rao and K.V. Rajulapati, Strengthening Mechanisms in Equiatomic Ultrafine Grained AlCoCrCuFeNi High-Entropy Alloy Studied by Micro- and Nanoindentation Methods, Acta Mater., 2017, 125, p 58–68.

R. Labusch, A Statistical Theory of Solid Solution Hardening, Phys. Stat. Sol., 1970, 41(2), p 659–669.

I. Toda-Caraballo and P.E.J. Rivera-Díaz-Del-Castillo, Modelling Solid Solution Hardening in High Entropy Alloys, Acta Mater., 2015, 85, p 14–23.

H. Yao, J.-W. Qiao, M.C. Gao, J.A. Hawk, S.-G. Ma and H. Zhou, MoNbTaV Medium-Entropy Alloy, Entropy, 2016, 18, p 189.

O.N. Senkov, J.M. Scott, S.V. Senkova, D.B. Miracle and C.F. Woodward, Microstructure and Room Temperature Properties of a High-Entropy TaNbHfZrTi Alloy, J. Alloys Compd., 2011, 509, p 6043–6048.

W. Guo, B. Liu, Y. Liu, T. Li, Fu. Ao, Q. Fang and Y. Nie, Microstructures and Mechanical Properties of Ductile NbTaTiV Refractory High Entropy Alloy Prepared by powder Metallurgy, J. Alloys Compd., 2019, 776, p 428–436.

O.N. Senkov, D.B. Miracle and K.J. Chaput, Development and Exploration of Refractory High Entropy Alloys-A Review, J. Mater. Res., 2018, 33(19), p 3092–3128.

W. Martienssen and H. Warlimont Eds., Handbook of Condensed Matter and Materials Data, Springer, New York, 2005

L.A. Gypen and A. Deruyttere, Multi-Component Solid Solution Hardening, J. Mater Sci., 1977, 12, p 1028–1033.

G.E. Dieter, Mechanical Metallurgy, 3rd ed. Mc Graw-Hill Book Co, New York, 1988, p 184–193

S. Chen, K.-K. Tseng, Y. Tong, W. Li, C.-W. Tsai, J.-W. Yeh and P.K. Liaw, Grain Growth and Hall-Petch Relationship in a Refractory HfNbTaZrTi High-Entropy Alloy, J. Alloys Compd., 2019, 795, p 19–26.

M.A. Meyers and K.K. Chawla, Mechanical Behavior of Materials, 2nd ed. Cambridge University Press, Cambridge, 2009, p 345–347

M.J. Jang, D.-H. Ahn, J. Moon, J.W. Bae, D. Yim, J.-W. Yeh, Y. Estrin and H.S. Kim, Constitutive Modeling of Deformation Behavior of High-Entropy Alloys with Face-Centered Cubic Crystal Structure, Mater. Res. Lett., 2017, 5(5), p 350–356.

H. Courtney, Mechanical Behavior of Materials, 2nd ed. New York, McGraw Hill Education, 2013, p 159–160

S. Peng, S. Mooraj, R. Feng, L. Liu, J. Ren, Y. Liu, F. Kong, Z. **ao, C. Zhu, P.K. Liaw and W. Chen, Additive Manufacturing of Three-Dimensional (3D)-Architected CoCrFeNiMn High- Entropy Alloy with Great Energy Absorption, Scr. Mater., 2021, 190, p 46–51.

K. Ma, H. Wen, Hu. Tao, T.D. Top**, D. Isheim, D.N. Seidman, E.J. Lavernia and J.M. Schoenung, Acta Mater., 2014, 62, p 141–155.

A. Belyakov, M. Tikhonova, P. Dolzhenko, T. Sakai and R. Kaibyshev, On Kinetics of Grain Refinement and Strengthening by Dynamic Recrystallization, Adv. Eng. Mater., 2019, 21, p 1800104.

P. Zhang, S.X. Li and Z.F. Zhang, General Relationship Between Strength and Hardness, Mater. Sci. Eng. A, 2011, 529(1), p 62–73.

Acknowledgments

This work is supported by the International Advanced Research Centre for Powder Metallurgy and New Materials (ARCI). The authors sincerely thank late Dr. G. Padmanabham, former Director of ARCI, for his support in carrying out this work.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Kanchi, A., Rajulapati, K.V., Rao, B.S. et al. Influence of Thermomechanical Processing on Microstructure and Mechanical Properties of MoNbTaW Refractory High-Entropy Alloy. J. of Materi Eng and Perform 31, 7964–7972 (2022). https://doi.org/10.1007/s11665-022-06855-9

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-022-06855-9