Abstract

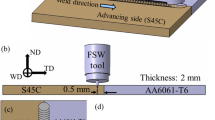

In order to further understand the role of MXene-Ti3C2 in oil–solid synergistic lubrication, three kinds of microporous channel composites, M50, M50-Sn-Ag-Cu and M50-Sn-Ag-Cu-Ti3C2, were designed and prepared in this study. Tribological behaviors under different environmental conditions of oil lubrication and dry friction were analyzed. The results show that M50-Sn-Ag-Cu-Ti3C2 exhibits excellent tribological properties under oil lubrication. Mxene-Ti3C2 enhances the strength of solid lubricant film, so that the oil film can give full play to the antifriction and wear resistance of solid lubricant film. The synergistic effect of lubricating oil, solid lubricants and bionic curved microchannel reduces the friction coefficient and wear rate. The vibration acceleration along the reciprocating direction is also reduced.

Similar content being viewed by others

References

J.F. Li, H.P. Zhao, H.J. Shi and X.Q. Feng, Effects of Surface Defects on the Rolling Contact Fatigue Behaviors of Cr4Mo4V Steel, J, Aeronautical Mater., 2005, 25(6), p 5–10.

J. Nygaard, M. Rawson, P. Danson and H. Bhadeshia, Bearing Steel Microstructures After Aircraft Gas Turbine Engine Service, J. Mater. Sci. Technol., 2014, 30(15), p 1911–1918.

F. Michael, G. Peter, H. Markus, M. Matthias, C. Francois and P. Dimitra, Experimental and Numerical Investigation of the Outer ring Cooling Concept in a Hybrid and in an all-Steel Ball Bearing Used in Aero-Engines by the Introduction of a Helical Duct, Aerospace, 2018, 5(1), p 23.

D.T. Gerardi, H.K. Trivedi and L. Rosado, Evaluation of Fatigue and Wear Characteristics of m50 Steel Using MIL-L-7808k, Int. J. of Fatigue., 1996, 18(3), p 191–196.

J.H. Xue, W. Li and C. Qin, The Scuffing Load Capacity of Involute Spur Gear Systems Based on Dynamic Loads and Transient Thermal Elastohydrodynamic Lubrication, Tribol. Int., 2014, 79, p 74–83.

C. Gachot, A. Rosenkranz, S.M. Hsu and H.L. Costa, A Critical Assessment of Surface Texturing for Friction and Wear Improvement, Wear, 2017, 372, p 21–41.

K. Holmberg, A. Matthews and H. Ronkainen, Coatings Tribology—Contact Mechanisms and Surface Design, Tribol. Int., 1998, 31, p 107–120.

L. Rapoport, A. Moshkovich, V. Perfilyev, I. Lapsker, G. Halperin, Y. Itovich and I. Etsion, Friction and wear of MoS2 films on laser textured steel surfaces, Surf. Coat. Technol., 2008, 202, p 3332–3340.

A. Moshkovith, V. Perfiliev, D. Gindin, N. Parkansky, R. Boxman and L. Rapoport, Surface Texturing using Pulsed Air Arc Treatment, Wear, 2007, 263, p 1467–1469.

X.Y. Liu, X.L. Shi, G.C. Lu, X.B. Deng, H.Y. Zhou, Z. Yan, Y. Chen and B. Xue, The Synergistic Lubricating Mechanism of Sn-Ag-Cu and C60 on the Worn Surface of M50 Self-Lubricating Material at Elevated Loads, J. Alloy. Compd., 2019, 777, p 271–284.

G.C. Lu, X.L. Shi, J. Zhang, H.Y. Zhou, Y.W. Xue and A. Ibrahim, Effects of Surface Composite Structure with Micro-Grooves and Sn-Ag-Cu on Reducing Friction and Wear of Ni3Al Alloys, Surf. Coat. Tech., 2020, 387, p 125540.

J. Zhang, G.C. Lu, X.L. Shi, Z.Y. Yang, Y.W. Xue and H.Y. Zhou, Improving Tribological Performance of Inconel 625 by Combining Groove-Textured Surfaces with Sn-Ag-Cu Solid Lubricant, J. Mater. Eng. Perform., 2021, 30, p 154–164.

X.Y. Liu, X.L. Shi, Y.C. Huang, X.B. Deng, G.C. Lu, Z. Yan and B. Xue, Tribological Behavior and Self-Healing Functionality of M50 Material Covered with Surface Micropores Filled with Sn-Ag-Cu, Tribol. Int., 2018, 128, p 365–375.

A. Mm, C. Gui, W.B. Bo, C. Vmf, D. Sk and D. Bm, Effective Usage of 2D Mxene Nanosheets as Solid Lubricant: Influence of Contact Pressure and Relative Humidity, Appl. Surf. Sci., 2020, 531, p 147311.

M. Marian, S. Tremmel, S. Wartzack, G. Song, B. Wang, Yu. Ji and A. Rosenkranz, Mxene Nanosheets as an Emerging Solid Lubricant for Machine Elements–Towards Increased Energy Efficiency and Service Life, Appl. Surf. Sci., 2020, 523, p 146503.

J.F. Chen and W.J. Zhao, Simple Method for Preparing Nanometer Thick Ti3C2TX Sheets Towards Highly Efficient Lubrication and Wear Resistance, Tribol. Int., 2021, 153, p 106598.

J. Hu, S.B. Li, J. Zhang, Q.Y. Chang, W.B. Yu and Y. Zhou, Mechanical Properties and Frictional Resistance of Al Composites Reinforced with Ti3C2Tx MXene, Chin. Chem. Lett., 2020, 31, p 996–999.

H. Yan, M. Cai, W. Li, X.Q. Fan and M.H. Zhu, Amino-Functionalized Ti3C2Tx with Anti-Corrosive/Wear Function for Waterborne Epoxy Coating, J. Mater. Sci. Technol., 2020, 54, p 144–159.

P. Chen, X. **ang, T.M. Shao, Y.Q. La and J.L. Li, Effect of Triangular Texture on the Tribological Performance of Die Steel with TiN Coatings Under Lubricated Sliding Condition, Appl. Surf. Sci., 2016, 389, p 361–368.

Y. Ando and T. Sumiya, Friction Properties of Micro/Nanogroove Patterns in Lubricating Conditions, Tribol. Int., 2020, 151, p 106428.

Y.W. Xue, X.L. Shi, Q.P. Huang, K.P. Zhang and C.H. Wu, Effects of Groove-Textured Surfaces with Sn-Ag-Cu and MXene-Ti3C2 on Tribological Performance of CSS-42L Bearing Steel in Solid-Liquid Composite Lubrication System, Tribol. Int., 2021, 161, p 107099.

D.Y. Zhang, F.F. Zhao, X. Wei, F. Gao, P.Y. Li and G.N. Dong, Effect of Texture Parameters on the Tribological Properties of Spheroidal Graphite Cast Iron Groove-Textured Surface Under Sand-Containing Oil Lubrication Conditions, Wear, 2019, 428, p 470–480.

X.F. Jiang, J.J. Song, S.N. Chen, Y.F. Su, H.Z. Fan, Y.S. Zhang and L.T. Hu, In-Situ Fabricated Bulk Metallic Glass/Graphite Composites with a 3D lubricating layer: Tribological Properties Under Dry Sliding and in Seawater, Tribol. Int., 2020, 148, p 106301.

W. Tillmann, D. Stangier, N.F. Lopes-Dias, D. Biermann and E. Krebs, Adjustment of Friction by Duplex-Treated, Bionic Structures for Sheet-Bulk Metal Forming, Tribol. Int., 2017, 111, p 9–17.

C.J. Su, Z.Y. Fu, H. Sun and X. Shen, Research on the Friction Performance of Bionic Surface Based on the Clamber Animal Foot Pad, Appl. Mech. Mater., 2013, 427–429, p 298–301.

F. Kairi, O. Masayuki, H. Hiromu and K. Shinpei, Bearing Characteristic of Journal Bearing Applied Biomimetics, Tribol. Int, 2020, 150, p 106345.

Z. Long, J. Wu, Z. Si, S. Sun, Z. Zhang, L. Song, Z. Liu and L. Ren, Bionic Coupling of Hardness Gradient to Surface Texture for Improved Anti-wear Properties, J. Bionic. Eng., 2016, 13(3), p 406–415.

W. Wang, X.Y. Wei, K. Meng, L.H. Zhong, Y. Wang and X.H. Yu, Bio-Tribology Properties of Bionic Carp Scale Morphology on Ti6A14V Surface, Adv. Mater. Sci. Eng., 2017, 281, p 012060.

Y. J. Wang, Study on Fabrication, Characterization and Tribological Properties of High Temperature Self-lubrication Metal Ceramics with Sweat gland Structure, Ph.D. Thesis, Wuhan University of Technology, 2008 (in Chinese)

T. Lv and X. Wang, Snake-Cree** Locomotion Experiment and Dynamic Imitation of Snake-Like Curves in Movement, J. Shanghai Jiaotong Univ., 1998, 32(1), p 132–135. (in Chinese)

American Society for Testing and Materials, Standard Test Method for Vickers hardness of Metallic Materials. ASTM E92-82e2, 2003

American Society for Testing and Materials, Standard Test Method for Wear Testing with a Pin-on-Disk Apparatus. ASTM G99-95, 1995

W.Q. Lian, Y.J. Mai, C.S. Liu, L.Y. Zhang, S.L. Li and X.H. Jie, Two-Dimensional Ti3C2 Coating as an Emerging Protective Solid-Lubricant for Tribology, Ceram. Int., 2018, 44(16), p 20154–20162.

Acknowledgments

This work was supported by the Guangdong Basic and Applied Basic Research Foundation (2021A1515010624). Authors are also grateful to X.L. Nie, Y.M. Li, M.J. Yang, W.T. Zhu, S.L. Zhao and L.Q. Qin in Material Research and Test Center of WUT for their kind help with SEM, EPMA and FESEM.

Author information

Authors and Affiliations

Corresponding authors

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Peng, F., Shi, X., Wu, C. et al. Effects of Curved Microchannel Surfaces with Sn-Ag-Cu and MXene-Ti3C2 on Tribological Performance of M50 Bearing Steel in Solid–Liquid Composite Lubrication System. J. of Materi Eng and Perform 31, 5837–5850 (2022). https://doi.org/10.1007/s11665-022-06611-z

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-022-06611-z