Abstract

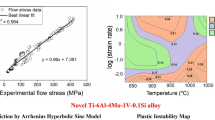

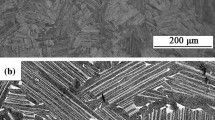

The flow behavior of Ti2AlNb-based alloy is critical to the research of hot forming due to its high sensitivity to the temperature and strain rate. The hot compression tests were conducted by using a Gleeble thermo-mechanical simulator in the temperature range of 950-1080 °C with strain rate from 0.001 to 10 s−1. The flow curves were modified firstly by taking into account the interface friction. In order to neutralize the thermal effect caused by high-speed deformation, the influence of strain rate on the deformation-induced temperature rise was evaluated, and the true temperature was obtained based on the collected stress–strain data. It was found that, under certain strain and strain rate, the true stress varied with the true temperature in an ‘inverted S’ format. Therefore, an ‘inverted S’ relation was adopted to calculate the flow stress at the given temperature. After the correction of flow stress, the constitutive model including the parabolic equation and modified Arrhenius equation in asymptotic form was established, and the discontinuous yielding and normal yielding behaviors were depicted, respectively. The constitutive model was integrated into the software DEFORM, by which the accuracy and predictability were verified.

Similar content being viewed by others

References

M. Peters, J. Kumpfert, C.H. Ward, and C. Leyens, Titanium Alloys for Aerospace Applications, Adv. Eng. Mater., 2003, 5(6), p 419–427

H. Zhang, C. Li, Z. Ma, L. Yu, and Y. Liu, Effect of Dual Aging Treatments on Phase Transformation and Microstructure in a Pre-Deformed Ti2AlNb-Based Alloy Containing O + β/B2 Structures, Vacuum, 2019, 164(February), p 175–180

D. Banerjee, A.K. Gogia, T.K. Nandi, and V.A. Joshi, A New Ordered Orthorhombic Phase in a Ti3Al-Nb Alloy, Acta Metall., 1988, 36(4), p 871–882

W. Chen, J.W. Li, L. Xu, and B. Lu, Development of Ti2AlNb Alloys: Opportunities and Challenges, Adv. Mater. Process., 2014, 172(5), p 23–27

C. Leyens, Advanced Materials and Coatings for Future Gas Turbine Applications, in 24th International Congress of Aeronautical Science, 2004

X. Chen, F.Q. **e, T.J. Ma, W.Y. Li, and X.Q. Wu, Microstructural Evolution and Mechanical Properties of Linear Friction Welded Ti2AlNb Joint during Solution and Aging Treatment, Mater. Sci. Eng. A, 2016, 668, p 125–136

G. Shen, A. Vedhanayagam, E. Kropp, and T. Altan, A Method for Evaluating Friction Using a Backward Extrusion-Type Forging, J. Mater. Process. Technol., 1992, 33(1), p 109–123

R.L. Goetz and S.L. Semiatin, The Adiabatic Correction Factor for Deformation Heating during the Uniaxial Compression Test, J. Mater. Eng. Perform., 2001, 10(6), p 710–717

R.J. Grylls, S. Banerjee, S. Perungulam, R. Wheeler, and H.L. Fraser, On the Discontinuous Yielding Phenomena Observed in a Nb-Ti-Al Alloy, Intermetallics, 1998, 6(7–8), p 749–752

I. Weiss and S.L. Semiatin, Thermomechanical Processing of Alpha Titanium Alloys—An Overview, Mater. Sci. Eng. A, 1999, 263(2), p 243–256

L. Zhu, J. Li, B. Tang, Y. Peng, H. Kou, and X. Xue, Flow Characteristics and Deformation Mechanisms for TiAl/Ti2AlNb Diffusion Bonded Joint, Mater. Chem. Phys., 2018, 220(August), p 216–224

J. Jia, K. Zhang, L. Liu, and F. Wu, Hot Deformation Behavior and Processing Map of a Powder Metallurgy Ti-22Al-25Nb Alloy, J. Alloys Compd., 2014, 600, p 215–221

R. Ebrahimi and A. Najafizadeh, A New Method for Evaluation of Friction in Bulk Metal Forming, J. Mater. Process. Technol., 2004, 152(2), p 136–143

A. Gholamzadeh and A. Karimi Taheri, The Prediction of Hot Flow Behavior of Al-6%Mg Alloy, Mech. Res. Commun., 2009, 36(2), p 252–259

Y.V.R.K. Prasad, D.H. Sastry, and S.C. Deevi, Processing Maps for Hot Working of a P/M Iron Aluminide Alloy, Intermetallics, 2000, 8(9–11), p 1067–1074

G. Krallics, Z. Bézi, and P. Bereczki, Hot Deformation Properties of 8006 Aluminium Alloy, Proc. Manuf., 2019, 37, p 174–181

R. Bobbili and V. Madhu, Physically-Based Constitutive Model for Flow Behavior of a Ti-22Al-25Nb Alloy at High Strain Rates, J. Alloys Compd., 2018, 762, p 842–848

F.J. Zerilli and R.W. Armstrong, Dislocation-Mechanics-Based Constitutive Relations for Material Dynamics Calculations, J. Appl. Phys., 1987, 61(5), p 1816–1825

Y.C. Lin and X.M. Chen, A Critical Review of Experimental Results and Constitutive Descriptions for Metals and Alloys in Hot Working, Mater. Des., 2011, 32(4), p 1733–1759

J. Yang, G. Wang, X. Jiao, Y. Li, and Q. Liu, High-Temperature Deformation Behavior of the Extruded Ti-22Al-25Nb Alloy Fabricated by Powder Metallurgy, Mater. Charact., 2018, 137(September 2017), p 170–179

Y. Sun, H. Zhang, Z. Peng Wan, L. Li Ren, and L. ** Hu, Establishment of a Novel Constitutive Model Considering Dynamic Recrystallization Behavior of Ti-22Al-25Nb Alloy during Hot Deformation, Trans. Nonferrous Met. Soc. China (Engl. Ed.), 2019, 29(3), p 546–557

C.M. Sellars and W.J. McTegart, On the Mechanism of Hot Deformation, Acta Metall., 1966, 14(9), p 1136–1138

D. Samantaray, S. Mandal, M. Jayalakshmi, C.N. Athreya, A.K. Bhaduri, and V. Subramanya Sarma, New Insights into the Relationship between Dynamic Softening Phenomena and Efficiency of Hot Working Domains of a Nitrogen Enhanced 316L(N) Stainless Steel, Mater. Sci. Eng. A, 2014, 598, p 368–375

Y.B. Tan, J.L. Duan, L.H. Yang, W.C. Liu, J.W. Zhang, and R.P. Liu, Hot Deformation Behavior of Ti-20Zr-6.5Al-4V Alloy in the Α + β and Single β Phase Field, Mater. Sci. Eng. A, 2014, 609, p 226–234

D.X. Wei, Y. Koizumi, and A. Chiba, Discontinuous Yielding and Microstructural Evolution of Ti-40 at.% Al Alloy Compressed in Single α-Hcp Phase Region, J. Alloys Compd., 2017, 693, p 1261–1276

L. Ma, M. Wan, W. Li, J. Shao, and X. Bai, Constitutive Modeling and Processing Map for Hot Deformation of Ti–15Mo–3Al-2.7Nb-0.2Si, J. Alloys Compd., 2019, 808, p 151759

A. Shamsolhodaei, A. Zarei-Hanzaki, M. Ghambari, and S. Moemeni, The High Temperature Flow Behavior Modeling of NiTi Shape Memory Alloy Employing Phenomenological and Physical Based Constitutive Models: A Comparative Study, Intermetallics, 2014, 53, p 140–149

Acknowledgments

The financial support by China National Science and Technology Major Project (Grant No. 2017-VI-0004-0075) is gratefully acknowledged by the authors.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Lv, M., Fu, Y., Yang, Z. et al. A Two-Stage Constitutive Model for Ti2AlNb Alloy Based on Asymptote Approach and Temperature-Corrected Stress. J. of Materi Eng and Perform 30, 1957–1969 (2021). https://doi.org/10.1007/s11665-021-05465-1

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-021-05465-1