Abstract

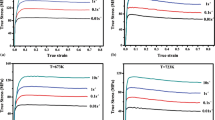

In this paper, the hot deformation behavior of A357 alloy was investigated by hot compression tests. Isothermal hot compression simulation tests for A357 alloy were carried out at the conditions of deformation temperature of 350-470 °C, strain rate of 0.001-10 s−1 and engineering strain of 50%. Based on the Prasad instability criterion and dynamic material model, the hot processing maps of A357 alloy were constructed. The microstructure of compressed samples at different areas of the hot processing map was characterized by metallographic and scanning electron microscope and transmission electron microscope. The experimental results showed that the unstable processing zone of A357 alloy was mainly distributed in the high strain rate (10 s−1) and low-temperature (350, 380 °C) region. With an increase in the strain, the unstable zone expanded from low temperature to high temperature (470 °C). The ideal deformation conditions were deformation temperatures of 380-410 °C and strain rates of 0.001-0.01 s−1, and deformation temperatures of 440-470 °C and strain rates of 0.01-1 s−1. When the A357 alloy was extruded with the optimal hot processing parameters, the results suggested that hot extrusion could make the microstructure uniform and fine, thereby improving mechanical properties, especially when the elongation was up to 19.5% higher than the as-cast A357 alloy.

Similar content being viewed by others

References

N.D. Alexopoulos and G. Pantelakis Sp, Quality Evaluation of A357 Cast Aluminum Alloy Specimens Subjected to Different Artificial Aging Treatment, Mater. Des., 2004, 25(5), p 419–430

O.S. Es-Said, D. Lee, W.D. Pfost, D.L. Thompson, M. Patterson, J. Foyos, and R. Marloth, Alternative Heat Treatments for A357-T6 Aluminum Alloy, Eng. Fail. Anal., 2002, 9(1), p 99–107

Z.W. Chen, P. Chen, and L. Fan, Effects of Melt Treatment on Dendrite Coherency of A357 Alloy, Adv. Mater. Res., 2011, 189-193, p 3886–3890

P.Y. Li, J. Jia, J.J. Guo, P.J. Li, and G.L. Shao, Effect of Melt Superheating on Microstructure and Mechanical Properties of A357 Alloy, T. Nonferr. Metal Soc., 1997, 7(3), p 94–98

M. Mostafaei, M. Ghobadi, G.B. Eisaabadi, M. Uludağ, and M. Tiryakioğlu, Evaluation of the Effects Of Rotary Degassing Processing Variables on the Quality of A357 Aluminum Alloy Castings, Metall. Mater. Trans. B, 2016, 47(6), p 3469–3475

K.N. Prabhu and P. Hemanna, Heat Transfer During Quenching of Modified and Unmodified Gravity Die-Cast A357 Cylindrical Bars, J. Mater. Eng. Perform., 2006, 15(3), p 311–315

Y.Z. Zou, Z.B. Xu, and J.M. Zeng, Effects of Secondary Dendrite Arm Spacing on Microporosity of A357 Alloy, Adv. Mater. Res., 2010, 97-101, p 781–784

J.W. Yeh and W.P. Liu, Cracking Mechanisms of Silicon Particles in an A357 Aluminum Alloy, Metall. Mater. Trans. A, 1996, 27(11), p 3558–3568

Y.C. Tzeng, V.S. Chengn, J.K. Nieh, H.Y. Bor, and S.L. Lee, Microstructure and Thermal Stability of A357 Alloy with and Without the Addition of Zr, J. Mater. Eng. Perform., 2017, 26(11), p 5511–5518

A. Saboori, M. Pavese, C. Badini, and A.R. Eivani, Studying the Age Hardening Kinetics of A357 Aluminum Alloys Through the Johnson-Mehl-Avrami Theory, Met. Powder Rep., 2017, 72(6), p 420–424

A. Bloyce and J.C. Summers, Static and Dynamic Properties of Squeeze-Cast A357-SiC Particulate Duralcan Metal Matrix Composite, Mater. Sci. Eng., A, 1991, 135(1-2), p 231–236

S. Dezecot and M. Brochu, Microstructural Characterization and High Cycle Fatigue Behavior of Investment Cast A357 Aluminum Alloy, Int. J. Fatigue, 2015, 77, p 154–159

W. Chen, Y.P. Guan, and Z.H. Wang, Hot Deformation Behavior of High Ti 6061 Al Alloy, T Nonferr. Metal Soc., 2016, 26(2), p 369–377

J. Peng, Y.J. Wang, L.P. Zhong, L.F. Peng, and F.S. Pan, Hot Deformation Behavior of Homogenized Al-32 Mg-04Er Aluminum Alloy, T Nonferr. Metal. Soc., 2016, 26(4), p 945–955

Q.G. Wang, Plastic Deformation Behavior of Aluminum Casting Alloys A356/357, Metall. Mater. Trans. A Phys. Metall. Mater. Sci., 2004, 35A(9), p 2707–2718

X.W. Yang, Z.H. Lai, J.C. Zhu, Y. Liu, and D. He, Hot Compressive Deformation Behavior of the As-Quenched A357 Aluminum Alloy, Mater. Sci. Eng., B, 2012, 177(19), p 1721–1725

M. Haghshenas, A. Zareihanzaki, and M. Jahazi, An Investigation to the Effect of Deformation-Heat Treatment Cycle on the Eutectic Morphology and Mechanical Properties of a Thixocast A356 Alloy, Mater. Charact., 2009, 60(8), p 817–823

A. Abbasi-Bani, A. Zarei-Hanzaki, M.H. Pishbin, and N. Haghdadi, A Comparative Study on the Capability of Johnson-Cook and Arrhenius-Type Constitutive Equations to Describe the Flow Behavior of Mg-6Al-1Zn Alloy, Mech. Mater., 2014, 71, p 52–61

A. Yanagida and J. Yanagimoto, A Novel Approach to Determine the Kinetics for Dynamic Recrystallization by Using the Flow Curve, J. Mater. Process. Tech., 2004, 151(1-3), p 33–38

Y. Prasad and S. Sasidhara, Hot Working Guide: A Compendium of Processing Maps, ASM International, Materials Park, 1997, p 25–177

Y. Prasad, H.L. Gegel, and S.M. Doraivelu, Modeling of Dynamic Material Behavior in Hot Deformation: Forging of Ti-6242, Metall. Trans. A, 1984, 15(10), p 1883–1892

H. Mirzadeh, A. Najafizadeh, and M. Moazeny, Flow Curve Analysis of 17-4 PH Stainless Steel Under Hot Compression Test, Metall. Mater. Trans. A, 2009, 40(12), p 2950–2958

T.K. Ha, W.J. Park, S.G. Ahn, and Y.W. Chang, Fabrication of Spray-Formed Hypereutectic Al-25Si Alloy and its Deformation Behavior, J. Mater. Process. Tech., 2002, 130, p 691–695

H.Z. Wang, K. Zhang, X.G. Li, and Y.J. Li, Effects of Homogenization on Hot Deformation Behaviors of AZ80 Magnesium Alloys with Processing Map, T. Nonferr. Metal Soc., 2010, 20(9), p 1671–1679

H.Z. Zhao, L. **ao, P. Ge, J. Sun, and Z.P. **, Hot Deformation Behavior and Processing Maps of Ti-1300 Alloy, Mater. Sci. Eng., A, 2014, 604, p 111–116

J.Z. Xu, X.J. Gao, Z.Y. Jiang, and D.B. Wei, A Comparison of Hot Deformation Behavior of High-Cr-White Cast Iron and High-Cr White Cast Iron/Low Carbon Steel Laminate, Steel Res. Int., 2016, 87(6), p 780–788

F.W. Kang, J.F. Sun, G.Q. Zhang, Z. Li, and J. Shen, Characteristics of Hot Compression Deformation and Microstructure Evolution of Spray Formed Nickel Base Superalloy, Acta. Metall. Sinica., 2007, 43(10), p 1053–1058

X. Yang and W. Li, Flow Behavior and Processing Maps of A Low-Carbon Steel During Hot Deformation[J], Metall. Mater. Trans. A, 2015, 46(12), p 6052–6064

B.L. **ao, J.Z. Fan, and X.F. Tian, Hot deformation and processing map of 15%SiCp/2009 Al composite, J. Mater. Sci., 2005, 40, p 5757–5762

B.L. **ao, J.Z. Fan, X.F. Tian et al., Hot Deformation and Processing Map of 15% SiC p/2009 Al Composite, J. Mater. Sci., 2005, 40(21), p 5757–5762

R.K.W. Marceau, G. Sha, and R.N. Lumley, Evolution of Solute Clustering in Al-Cu-Mg Alloys During Secondary Ageing, Acta Mater., 2010, 58(5), p 1795–1805

N. Chobaut, D. Carron, and J.M. Drezet, Characterisation of Precipitation Upon Cooling of an AA2618 Al-Cu-Mg Alloy, J. Alloys Compd., 2016, 654, p 56–62

Y. Prasad and T. Seshacharyulu, Modelling of hot deformation for microstructural control, Int. Meter. Rev., 1998, 43(6), p 243–258

G. Ganesan, K. Raghukandan, and R. Karthikeyan, Development of Processing Maps for 6061 Al/15% SiCp Composite Material, Mater. Sci. Eng., A, 2014, 369(1), p 230–235

S. Banerjee, P.S. Robi, and A. Srinivasan, Deformation Processing Maps for Control of Microstructure in Al-Cu-Mg Alloys Microalloyed with Sn, Metall. Mater. Trans. A, 2012, 43(10), p 3834–3849

A.K. Maheshwari, Prediction of flow Stress for Hot Deformation Processing, Comp. Mater. Sci., 2013, 69, p 350–358

M. Haghshenas, A. Zarei-Hanzaki, S.M. Fatemi-Varzaneh, and H. Abedi, Hot Deformation Behaviour of Thixocast A356 Aluminum Alloy During Compression at Elevated Temperature, Int. J. Mater. Form., 2008, 1(1), p 1001–1005

Acknowledgments

This study was funded by the National Natural Science Foundation of China (Grant No. 51901058)

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Kang, F., Wei, S., Zhang, J. et al. Hot Processing Maps and Microstructural Characteristics of A357 Alloy. J. of Materi Eng and Perform 29, 7352–7360 (2020). https://doi.org/10.1007/s11665-020-05210-0

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-020-05210-0