Abstract

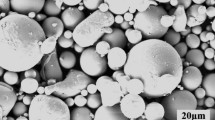

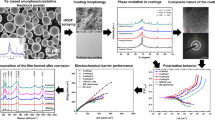

To improve the corrosion resistance of Q235 carbon steel in 3.5 wt.% NaCl solution, an Fe-based amorphous coating was deposited on the surface of Q235 carbon steel by detonation gun (D-gun) spraying method. It was found that the coating showed a typical amorphous phase with hardness of about 850 Hv. The morphology of the microdomains showed that the coating was dense, contained no visible defects, and its porosity was about 0.7%. The micro-regional element analysis indicates the formation of Cr7C3 during the spraying process. Compared with Q235 carbon steel, electrochemical tests show that the coating has higher pitting corrosion potential (− 296 versus − 914 mV for Q235 carbon steel), and lower corrosion current density (1.7 versus 24.6 μA/cm2 for Q235 carbon steel), and larger polarisation resistance (11,306.8 versus 1,821.1 Ω cm2 for Q235 carbon steel), indicating that the coating is more resistant to corrosion. XPS analysis shows that the coating forms a passivation film, rich in Cr and Mo, in the 3.5 wt.% NaCl solution. It exhibits excellent corrosion resistance, and limits the severity of corrosion, of carbon steel.

Similar content being viewed by others

References

J.C. Qiao, Q. Wang, J.M. Pelletier, H. Kato, R. Gasalini, D. Grespo, E. Pineda, Y. Yao, and Y. Yang, Structural Heterogeneities and Mechanical Behavior of Amorphous Alloys, Prog. Mater. Sci., 2019, 104, p 250-329

H.M. Zhai, Y.H. Xu, Y. Du, H.F. Wang, and F. Liu, Strain Rate Sensitivity and Deformation Behavior in a Ti-based Bulk Metallic Glass Composite, J. Non-Cryst. Solids., 2017, 471, p 128-136

J.C. Qiao, Y. Yao, J.M. Pelletier, and L.M. Keer, Understanding of Micro-alloying on Plasticity in Cu46Zr47-xAl7Dyx (0≤ x ≤ 8) Bulk Metallic Glasses Under Compression: Based on Mechanical Relaxations and Theoretical Analysis, Int. J. Plasticity, 2016, 82, p 62-75

H.M. Zhai, H.F. Wang, and F. Liu, A Strategy for Designing Bulk Metallic Glass Composites with Excellent Work-hardening and Large Tensile Ductility, J. Alloy. Compd., 2016, 685, p 322-330

C.L. Zhao, C.C. Dun, Q.K. Man, and B.L. Shen, Enhancement of Plastic Deformation in FeCoNbB Bulk Metallic Glass with Superhigh Strength, Intermetallics, 2013, 32, p 408-412

B.L. Shen, A. Inoue, and C.T. Chang, Superhigh Strength and Good Soft-magnetic Properties of (Fe, Co)–B–Si–Nb Bulk Glassy Alloys with High Glass-forming Ability, Appl. Phys. Lett., 2004, 85, p 4911

Nilanjan Mahata, A. Banerjee, P. Bijalwan, P.K. Rai, S. Sangal, and K. Mondal, Electrochemical Behavior of HVOF-Sprayed Amorphous and Nanocrystalline Fe-Based Fe73.13Si11.12B10.79Cr2.24C2.72 Composite Coatings, J. Mater. Eng. Perform., 2017, 26, p 5538-5552

E. Sadeghi and S. Joshi, Chlorine-induced High-temperature Corrosion and Erosion-corrosion of HVAF and HVOF-sprayed Amorphous Fe-based Coatings, Surf. Coat. Tech., 2019, 371, p 20-35

Z.H. Chu, F.S. Wei, X.W. Zheng, C.Y. Zhang, and Y. Yang, Microstructure and Properties of TiN/Fe-based Amorphous Composite Coatings Fabricated by Reactive Plasma Spraying, J. Alloy. Compd., 2019, 785, p 206-213

H. Wu, X.D. Lan, Y. Liu, F. Li, W.D. Zhang, Z.J. Chen, X.F. Zai, and H. Zeng, Fabrication, Tribological and Corrosion Behaviors of Detonation Gun Sprayed Fe-based Metallic Glass Coating, T. Nonferr. Metal. Soc., 2016, 26, p 1629-1637

H. Gerengi,, H.I. Sahin, WITHDRAWN: Schinopsis Lorentzii Extract as a Green Corrosion Inhibitor for Low Carbon Steel in 1M HCl Solution, J. Ind. Eng. Chem., 2012

J. Ma, Y.D. He, J. Wang, and B.D. Sun, High Temperature Corrosion Behaviour of Microcrystalline Aluminide Coating on Q235 Steel, Brit. Corros. J., 2009, 44, p 157-160

Q.Y. Wang, S.L. Bai, and Z.D. Liu, Corrosion Behavior of Hastelloy C22 Coating Produced by Laser Cladding in Static and Cavitation Acid Solution, T. Nonferr. Metal. Soc., 2014, 24, p 1610-1618

Q.J. Zhu, K. Wang, and X.H. Wang, Corrosion Behavior of Cold-Spray Aluminum Coating in Marine Environment, Adv. Mater., 2010, 160-162, p 364-368

B.Y. Fu, D.Y. He, L.D. Zhao, and X.Y. Li, Microstructure and Properties of Arc Sprayed Coatings Containing Fe-based Amorphous Phase, Surf. Eng., 2009, 25, p 333-337

M.Q. Wang, Z.H. Zhou, Q.J. Wang, Z.H. Wang, X. Zhang, and Y.Y. Liu, Role of Passive Film in Dominating the Electrochemical Corrosion Behavior of FeCrMoCBY Amorphous Coating, J. Alloy. Compd., 2019, 811

L. Singh, V. Chawla, and J.S. Grewal, A Review on Detonation Gun Sprayed Coatings, J. Miner. Mater. Char. Eng., 2012, 11, p 243-265

Y. Wang, Z. Jiang, Z. Yao, and H. Tang, Microstructure and Corrosion Resistance of Ceramic Coating on Carbon Steel Prepared by Plasma Electrolytic Oxidation, Surf. Coat. Tech., 2010, 204, p 1685-1688

W.P. Tian, H.W. Yang, and S.D. Zhang, Synergistic Effect of Mo, W, Mn and Cr on the Passivation Behavior of a Fe-Based Amorphous Alloy Coating, Acta. Metall. Sin., 2018, 1, p 1-13

Y.S. Tao, T.Y. **ong, C. Sun, L.Y. Kong, X.Y. Cui, T.F. Li, and G.L. Song, Microstructure and Corrosion Performance of A Cold Sprayed Aluminium Coating on AZ91D Magnesium Alloy, Corros. Sci, 2010, 52, p 3191-3197

Q. Jiang, Q. Miao, F. Tong, Y. Xu, B.L. Ren, Z.M. Liu, and Z.J. Yao, Electrochemical Corrosion Behavior of Arc Sprayed Al–Zn–Si–RE Coatings on Mild Steel in 3.5% NaCl Solution, T. Nonferr. Metal. Soc., 2014, 24, p 2713-2722.

M.M. Verdian, K. Raeissi, and M. Salehi, Role of Thickness on Electrochemical Behaviour of Ni2Si Coatings in NaCl Solution, T. IMF, 2015, 93, p 164-168

X.R. Wang, J. Wu, and X.G. Hu, Corrosion Behavior of Electroless Deposited Fe-Zn Coating, Appl. Mech. Mater., 2011, 117, p 81-84

M.A. Zavareh, A.A.D.M. Sarhan, B.B.A. Razak, and W.J. Basirun, The Tribological and Electrochemical Behavior of HVOF-sprayed Cr3C2–NiCr Ceramic Coating on Carbon Steel, Ceram. Int., 2015, 41, p 5387-5396

A. Madhan Kumar, S. Hwan Kwon, H. Chul Jung, Y.H. Park, H.J. Kim, and K.S. Shin, Fabrication and Electrochemical Corrosion Behavior of PEO Coatings on Strip-Cast AZ31Mg Alloy in 3.5% NaCl Solution, Ind. Eng. Chem. Res., 2014, 53, p 9703-9713

J.W. Lee, J.G. Duh, and S.Y. Tsai, Corrosion Resistance and Microstructural Evaluation of the Chromized Coating Process in A Dual Phase Fe-Mn-Al-Cr Alloy, Surf. Coat. Tech., 2002, 153, p 59-66

R. Zeng, J. Chen, J. Kuang, and Y. Wang, Influence of Silane on Corrosion Resistance of Magnesium Alloy AZ31 with Thermally Sprayed Aluminum Coatings, Rare Metals, 2010, 29, p 193-197

M. Stratmann, The Atmospheric Corrosion of Iron-A Discussion of the Physico-Chemical Fundamentals of this Omnipresent Corrosion Process Invited Review, Berichte der Bunsengesellschaft für physikalische Chemie, 1990, 94, p 626-639

Y. Wang, Y.G. Zheng, W. Ke, W.H. Sun, W.L. Hou, X.C. Chang, and J.Q. Wang, Slurry Erosion–corrosion Behaviour of High-velocity Oxy-fuel (HVOF) Sprayed Fe-based Amorphous Metallic Coatings for Marine Pump in Sand-containing NaCl Solutions, Corros. Sci., 2011, 53, p 3177-3185

S. Frangini, A. Masci, and A. Di Bartolomeo, Cr7C3-based Cermet Coating Deposited on Stainless Steel by Electrospark Process: Structural Characteristics and Corrosion Behavior, Surf. Coat. Tech., 2002, 149, p 279-286

X.Q. Li, W.S Li, H.M. Zhai, S. Cui, X.L. Qiu, and W.C. Ning, Dry Sliding Wear Behaviors of Fe-based Amorphous Metallic Coating Synthesized by Detonation Spraying, Journal of Non-Crystalline Solids, 2020, 537:120018

C.P. Jiang, The Microstructure and Properties of Fe-based Amorphous Coatings Fabricated by Plasma Spraying, Changan university, 2015

C.N. C, Principles of Electrochemistry of Corrosion, Chemical Industry Press, 2008

J. Wu, S.D. Zhang, W.H. Sun, Y. Gao, and J.Q. Wang, Enhanced Corrosion Resistance in Fe-based Amorphous Coating through Eliminating Cr-depleted Zones, Corros. Sci., 2018, 136, p 161-173

G.B. Shan, Y.Z. Chen, Y.J. Li, C.Y. Zhang, H. Dong, Y.B. Cong, W.X. Zhang, L.K. Huang, T. Suo, and F. Liu, High Temperature Creep Resistance of Thermally Stable Nanocrystalline Fe-5 at.% Zr Steel, Scripta Mater., 2020, 179, p 1–5

Acknowledgment

Haimin Zhai would like to thank the Natural Science Foundation of China (No. 51901092) and Hongliu Distinguished Young Talent Support Program Project of Lanzhou University of Technology. Wensheng Li is grateful to the Supporting Program of National Natural Science Foundation of China (51674130) and the National High-end Foreign Experts Program of China (GDT20186200331), and the International Science and Technology Correspondent Program of Gansu province (17JR7WA017) and the program of “Science and Technology International Cooperation Demonstrative Base of Metal Surface Engineering along the Silk Road”.

Author information

Authors and Affiliations

Corresponding authors

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Ning, W., Zhai, H., **ao, R. et al. The Corrosion Resistance Mechanism of Fe-Based Amorphous Coatings Synthesised by Detonation Gun Spraying. J. of Materi Eng and Perform 29, 3921–3929 (2020). https://doi.org/10.1007/s11665-020-04876-w

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-020-04876-w