Abstract

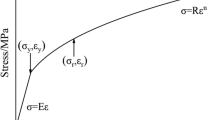

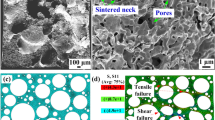

In this paper, the elastoplastic and creep constitutive behaviors of sintered silver with varying amounts of nickel-modified multiwall carbon nanotubes are studied through a systematic investigation of the nanoindentation test. Elastoplastic stress–strain curves for the sintered silver with different additive content are obtained based on reverse analysis. The addition of nickel-modified multiwall carbon nanotubes reduced the yielding stress from 110.68 MPa to 61.61 MPa and generally increased the strain-hardening exponent from 0.26 to 0.41. The initial and steady-state creep stress exponent remained almost unchanged. However, the creep coefficient increased remarkably. Otherwise, the yielding stress was confirmed to agree well with the Hall–Petch relation, and the hardening exponent was found to follow Morrison’s law. The creep exponents and creep coefficients were also obtained and shown to be highly related to the particle size and positively correlated with porosity. The creep regime at room temperature was confirmed to obey Sherby’s model. This investigation shows the effect of additive content on sintered silver. The study given in this paper could deepen the understanding of the strengthening effect of nickel-modified multiwall carbon nanotubes on the mechanical performance of sintered silver at room temperature.

Similar content being viewed by others

References

T.F. Chen and K.S. Siow, Comparing the mechanical and thermal-electrical properties of sintered copper (Cu) and sintered silver (Ag) joints. J. Alloys Compd. 866, 158783 (2021).

J. Dai, J. Li, P. Agyakwa, M. Corfield, and C.M. Johnson, Comparative thermal and structural characterization of sintered nano-silver and high-lead solder die attachments during power cycling. IEEE Trans. Device Mater. Reliab. 18(2), 256 (2018).

H. Zhang, Z. Zhao, G. Zou, W. Wang, L. Liu, G. Zhang, and Y. Zhou, Failure analysis and reliability evaluation of silver-sintered die attachment for high-temperature applications. Microelectron. Reliab. 94, 46 (2019).

F. Khodabakhshi, M. Zareghomsheh, and G. Khatibi, Nanoindentation creep properties of lead-free nanocomposite solders reinforced by modified carbon nanotubes. Mater. Sci. Eng. A 797, 140203 (2020).

Y.D. Han, Y. Gao, S.T. Zhang, H.Y. **g, J. Wei, L. Zhao, and L.Y. Xu, Study of mechanical properties of Ag nanoparticle-modified graphene/Sn-Ag-Cu solders by nanoindentation. Mater. Sci. Eng. A 761, 138051 (2019).

Y. Huang, Z. **u, G. Wu, Y. Tian, and P. He, Sn-3.0 Ag-0.5 Cu nanocomposite solders reinforced by graphene nanosheets. J. Mater. Sci. Mater. Electron. 27(7), 6809 (2016).

F. Khodabakhshi, R. Sayyadi, and N.S. Javid, Lead free Sn-Ag-Cu solders reinforced by Ni-coated graphene nanosheets prepared by mechanical alloying: microstructural evolution and mechanical durability. Mater. Sci. Eng. A 702, 371 (2017).

A. Sharma, H.R. Sohn, and J.P. Jung, Effect of graphene nanoplatelets on wetting, microstructure, and tensile characteristics of Sn-3.0 Ag-0.5 Cu (SAC) alloy. Metall. Mater. Trans. A 47, 494 (2016).

S. Xu, Y.C. Chan, K. Zhang, and K.C. Yung, Interfacial intermetallic growth and mechanical properties of carbon nanotubes reinforced Sn3.5Ag0.5Cu solder joint under current stressing. J. Alloys Compd. 595, 92 (2014).

Z. Zhu, Y.C. Chan, Z. Chen, C.L. Gan, and F. Wu, Effect of the size of carbon nanotubes (CNTs) on the microstructure and mechanical strength of CNTs-doped composite Sn0.3Ag0.7Cu-CNTs solder. Mater. Sci. Eng. A 727, 160 (2018).

S.M.L. Nai, J. Wei, and M. Gupta, Effect of carbon nanotubes on the shear strength and electrical resistivity of a lead-free solder. J. Electron. Mater. 37(4), 515 (2008).

Y.D. Han, H.Y. **g, S.M.L. Nai, L.Y. Xu, C.M. Tan, and J. Wei, Interfacial reaction and shear strength of Ni-coated carbon nanotubes reinforced Sn-Ag-Cu solder joints during thermal cycling. Intermetallics 31, 72 (2012).

H. Sun, Y.C. Chan, and F. Wu, Effect of CNTs and Ni coated CNTs on the mechanical performance of Sn57.6Bi0.4Ag BGA solder joints. Mater. Sci. Eng. A 656, 249 (2016).

Z. Yang, W. Zhou, and P. Wu, Effects of Ni-coated carbon nanotubes addition on the electromigration of Sn-Ag-Cu solder joints. J. Alloys Compd. 581, 202 (2013).

K.K. Xu, L. Zhang, and N. Jiang, Effect of CNTs on the intermetallic compound growth between Sn solder and Cu substrate during aging and reflowing. J. Mater. Sci. Mater. Electron. 32(3), 2655 (2021).

H. Wang, X. Hu, and X. Jiang, Effects of Ni modified MWCNTs on the microstructural evolution and shear strength of Sn-3.0 Ag-0.5 Cu composite solder joints. Mater Charact 163, 110287 (2020).

M.A. Hanim, A.B. Dasan, T.T. Dele-Afolabi, T. Ariga, and K. Vidyatharran, Influence of porous Cu interlayer on the intermetallic compound layer and shear strength of MWCNT-reinforced SAC 305 composite solder joints. J. Mater. Sci. Mater. Electron. 32(4), 4515 (2021).

T.T. Dele-Afolabi, M.A. Hanim, O.J. Ojo-Kupoluyi, and R. Calin, Impact of different isothermal aging conditions on the IMC layer growth and shear strength of MWCNT-reinforced Sn-5Sb solder composites on Cu substrate. J. Alloys Compd. 808, 151714 (2019).

N.S. Javid, R. Sayyadi, and F. Khodabakhshi, Lead-free Sn-based/MW-CNTs nanocomposite soldering: effects of reinforcing content, Ni-coating modification, and isothermal ageing treatment. J. Mater. Sci. Mater. Electron. 30(5), 4737 (2019).

T.T. Dele-Afolabi, M.A. Hanim, K. Vidyatharran, K.A. Matori, O.S. Azlina, and R. Calin, Interfacial microstructure evolution and shear strength of MWCNTs-reinforced Sn-1.0 Ag-0.5 Cu (SAC105) composite solder interconnects on plain Cu and ENIAg surface finish. J. Mater. Sci. Mater. Electron. 33, 8233–8246 (2022).

H. Wang, X. Hu, and X. Jiang, Effects of Ni modified MWCNTs on the microstructural evolution and shear strength of Sn-3.0Ag-0.5 Cu composite solder joints. Mater Charact 163, 110287 (2020).

X. Long, Z. Li, X. Lu, H. Guo, C. Chang, Q. Zhang, and J. Liu, Mechanical behaviour of sintered silver nanoparticles reinforced by SiC microparticles. Mater. Sci. Eng. A 744, 406 (2019).

B. Hu, F. Yang, Y. Peng, C. Hang, H. Chen, C. Lee, and M. Li, Effect of SiC reinforcement on the reliability of Ag nanoparticle paste for high-temperature applications. J. Mater. Sci. Mater. Electron. 30(3), 2413 (2019).

J. Szałapak, K. Kiełbasiński, Ł Dybowska-Sarapuk, J. Krzeminski, M. Teodorczyk, T. Kowaluk, and M. Jakubowska, Influence of carbon nanoparticles additives on nanosilver joints in LTJT technology. ASME. J. Electron. Packag. 143(3), 034501 (2021).

Y. Dai, Z. Zan, S. Zhao, Y. Li, and F. Qin, Shearing fracture toughness enhancement for sintered silver with nickel coated multiwall carbon nanotubes additive. Eng. Fract. Mech. 260, 108181 (2022).

S.R. Bakshi, D. Lahiri, and A. Agarwal, Carbon nanotube reinforced metal matrix composites: a review. Int. Mater. Rev. 55(1), 41 (2010).

A. Patil, M.S.K.K.Y. Nartu, F. Ozdemir, R. Banerjee, R.K. Gupta, and T. Borkar, Strengthening effects of multi-walled carbon nanotubes reinforced nickel matrix nanocomposites. J. Alloys Compd. 876, 159981 (2021).

S. Kim, S. Park, D. Kim, and C. **, Thermal diffusivity of Ag/CNT-Added Ag nanocomposites prepared by spark plasma sintering. Int. Cast Met. J. Precis. Eng. Manuf. 21(7), 1357 (2020).

A. Oluwalowo, N. Nguyen, S. Zhang, J.G. Park, and R. Liang, Electrical and thermal conductivity improvement of carbon nanotube and silver composites. Carbon 146, 224 (2019).

F. Wang, Z. Chen, H. He, and N. Nie, Study on the effect of CNT on the improved mechanical performance of flexible Ag NPs/CNT based electronics. AIP Adv. 9(4), 045318 (2019).

V. Gopee, O. Thomas, C. Hunt, V. Stolojan, J. Allam, and S.R.P. Silva, Carbon nanotube interconnects realized through functionalization and sintered silver attachment. ACS Appl. Mater. Interfaces 8(8), 5563 (2016).

D. Jia, J. Ma, X. Gan, J. Tao, M. **e, J. Yi, and Y. Liu, A Comparison study of Ag composites prepared by spark plasma sintering and hot pressing with silver-coated CNTs as the reinforcements. Materials 12(12), 1949 (2019).

X. Li, G. Chen, L. Wang, Y.H. Mei, X. Chen, and G.Q. Lu, Creep properties of low-temperature sintered nano-silver lap shear joints. Mater. Sci. Eng. A 579, 108 (2013).

G. Chen, X.H. Sun, P. Nie, Y.H. Mei, G.Q. Lu, and X. Chen, High-temperature creep behavior of low-temperature-sintered nano-silver paste films. J. Electron. Mater. 41(4), 782 (2012).

D. Leslie, A. Dasgupta, and C. Morillo, Viscoplastic properties of pressure-less sintered silver materials using indentation. Microelectron. Reliab. 74, 121 (2017).

X. Long, B. Hu, Y. Feng, C. Chang, and M. Li, Correlation of microstructure and constitutive behaviour of sintered silver particles via nanoindentation. Int. J. Mech. Sci. 161, 105020 (2019).

X. Long, Q. Jia, Z. Shen, M. Liu, and C. Guan, Strain rate shift for constitutive behaviour of sintered silver nanoparticles under nanoindentation. Mech. Mater. 158, 103881 (2021).

H. Zhang, Y. Liu, L. Wang, F. Sun, X. Fan, and G. Zhang, Indentation hardness, plasticity and initial creep properties of nanosilver sintered joint. Results Phys. 12, 712 (2019).

E. Kolbinger, S. Kuttler, S. Wagner, and M. Schneider-Ramelow, Investigation of the mechanical properties of corroded sintered silver layers by using Nanoindentation. Microelectron. Reliab. 114, 113889 (2020).

G. He, W. Hongcheng, and Y. Yao, Creep of sintered porous micron-silver: nanoindentation experiment and theoretical analysis. J. Mater. Sci. 56(32), 18281 (2021).

F. Qin, S. Zhao, Y. Dai, L. Liu, T. An, P. Chen, and Y. Gong, Indentation tests for sintered silver in die-attach interconnection after thermal cycling. J. Electron. Packag. 144, 3 (2022).

D. Tabor, The hardness of metals. Published in the Oxford Classics series (New York: Oxford Univ. Press, 2000).

K.L. Johnson, Contact mechanics (London: Cambridge Univ. Press, 1985).

J.M. Antunes, J.V. Fernandes, L.F. Menezes, and B.M. Chaparro, A new approach for reverse analyses in depth-sensing indentation using numerical simulation. Acta Mater. 55(1), 69 (2007).

U. Landman, W.D. Luedtke, N.A. Burnham, and R.J. Colton, Atomistic mechanisms and dynamics of adhesion, nanoindentation, and fracture. Science 248(4954), 454 (1990).

M.E. Kassner, P. Kumar, and W. Blum, Harper–Dorn creep. Int. J. Plast. 23(6), 980 (2007).

A.C. Fischer-Cripps, A simple phenomenological approach to nanoindentation creep. Mater. Sci. Eng. A 385(1–2), 74 (2004).

L. Shen, P. Septiwerdani, and Z. Chen, Elastic modulus, hardness and creep performance of SnBi alloys using nanoindentation. Mater. Sci. Eng. A 558, 253 (2012).

Y. Li, X. Fang, S. Lu, Q. Yu, G. Hou, and X. Feng, Effects of creep and oxidation on reduced modulus in high-temperature nanoindentation. Mater. Sci. Eng. A 678, 65 (2016).

P.S. Singh, Z. Liang, G.M. Pharr, and M.P. de Boer, Creep of a thermally stable nanocrystalline nickel tungsten alloy as measured by high temperature nanoindentation. Mater. Sci. Eng. A 784, 139309 (2020).

B.N. Lucas and W.C. Oliver, Indentation power-law creep of high-purity indium. Metall. Mater. Trans. A 30(3), 601 (1999).

M.J. Mayo and W.D. Nix, A micro-indentation study of superplasticity in Pb, Sn, and Sn-38 wt% Pb. Acta Metall. 36(8), 2183 (1988).

B. Merle, W.H. Higgins, and G.M. Pharr, Critical issues in conducting constant strain rate nanoindentation tests at higher strain rates. J. Mater. Res. 34(20), 3495 (2019).

W.C. Oliver and G.M. Pharr, Measurement of hardness and elastic modulus by instrumented indentation: advances in understanding and refinements to methodology. J. Mater. Res. 19(1), 3 (2004).

H. Li and A.H.W. Ngan, Size effects of nanoindentation creep. J. Mater. Res. 19(2), 513 (2004).

G. **ao, Y. Ma, X. Ji, T. Wang, X. Shu, and E. Liu, Effective acquisition of elastoplastic and creep parameters of lead-free solder alloy from high-temperature micro-indentation eliminating the size effect. Mech. Mater. 160, 103985 (2021).

M. Dao, N.V. Chollacoop, K.J. Van Vliet, T.A. Venkatesh, and S. Suresh, Computational modeling of the forward and reverse problems in instrumented sharp indentation. Acta Mater. 49(19), 3899 (2001).

Y. Choi, H. Lee, and D. Kwon, Analysis of sharp-tip-indentation load-depth curve for contact area determination taking into account pile-up and sink-in effects. J. Mater. Res. 19(11), 3307 (2004).

A.A. Wereszczak, D.J. Vuono, H. Wang, M.K. Ferber, Z. Liang, Properties of bulk sintered silver as a function of porosity. Oak Ridge Natl. Lab., ORNL, Oak Ridge, TN (U. S.), (2012).

W.B. Morrison, The effect of grain size on the stress–strain relationship in low-carbon steel. ASM Trans. Q. 59(4), 824 (1966).

L. Thébaud, P. Villechaise, C. Crozet, A. Devaux, D. Béchet, J.M. Franchet, and J. Cormier, Is there an optimal grain size for creep resistance in Ni-based disk superalloys? Mater. Sci. Eng. A 716, 274 (2018).

T. Sakthivel, G. Sasikala, and M. Vasudevan, Role of microstructures on heterogeneous creep behaviour across P91 steel weld joint assessed by impression creep testing. Mater Charact 159, 109988 (2020).

O.D. Sherby, Factors affecting the high temperature strength of polcyrystalline solids. Acta Metall. 10(2), 135 (1962).

Y. Dai, Z. Zan, S. Zhao, and F. Qin, Mode II cohesive zone law of porous sintered silver joints with nickel coated multiwall carbon nanotube additive under ENF test. Theor. Appl. Fract. Mech. 121, 103498 (2022).

Acknowledgments

The authors acknowledge the support from the National Natural Science Foundation of China (12272012) and the Bei**g Municipal Natural Science Foundation (2204074).

Author information

Authors and Affiliations

Corresponding authors

Ethics declarations

Conflict of interest

We declare that we have no financial and personal relationships with other people or organizations that can inappropriately influence our work, there is no professional or other personal interest of any nature or kind in any product, service or company that could be construed as influencing the position presented in, or the review of, this manuscript.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Dai, Y., Zan, Z., Zhao, L. et al. Nanoindentation Elastoplastic and Creep Behaviors of Sintered Nano-Silver Doped with Nickel-Modified Multiwall Carbon Nanotube Filler. J. Electron. Mater. 53, 1035–1057 (2024). https://doi.org/10.1007/s11664-023-10871-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11664-023-10871-3