Abstract

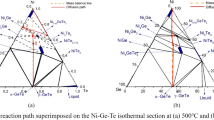

SnSe-, SnTe- and Se-Sn-Te-based alloys are important materials for thermoelectric and optical recording applications and Ni is highly recommended as barrier layer material. In this study, the interfacial reactions in Ni/SnSe, Ni/SexTe1−x, Ni/SnTe, and Ni/SnTe0.9Se0.1 are systematically investigated to provide fundamental understanding. The substrates are prepared with pure constituent elements and electroplated with a layer of Ni. The reaction couples are heat-treated, and their reaction phases are determined. Based on assessment of the literature results, the phase equilibria isothermal sections of the related material systems are proposed. The reaction paths in these couples are determined and illustrated with the proposed isothermal sections. The reaction paths in the Ni/SnSe couple reacted at 250°C and 300°C are both Ni/Ni3Sn/Ni3Sn2/NiSe/Ni5.62SnSe2/Ni3SnSe/ NiSnSe/SnSe. Both NiSnSe and Ni3SnSe are likely metastable ternary phases formed by rapid diffusion of Ni atoms into the SnSe substrate. The reaction path in the Ni/SexTe1−x couples reacted at 200°C is Ni/Ni3Te2/τ/SexTe1−x and in the Ni/SnTe couples reacted at 400°C is Ni/Ni3Sn/Ni3Sn2/Ni5.78SnTe2/Ni3SnTe2/SnTe. In the Ni/SnTe0.9Se0.1 couple reacted at 400°C, the reaction path is the same as that of Ni/SnTe. The reaction rates decrease with lower reaction temperatures, and the reaction zone grows thicker with longer reaction time. Based on the morphology and reaction phase sequences, it is concluded Ni is the fastest diffusion species in the diffusion couples among Ni, Se, Sn and Te.

Similar content being viewed by others

References

S.M. Lélé, World Dev. (1991). https://doi.org/10.1016/0305-750x(91)90197-p

B. Prindle, M. Eldridge, M. Eckhardt, A. Frederick, The Twin Pillars of Sustainable Energy: Synergies between Energy Efficiency and Renewable Energy Technology and Policy, ACEEE Rep. #E074, (2007).

D. Beretta, N. Neophytou, J.M. Hodges, M.G. Kanatzidis, D. Narducci, M. Martin- Gonzalez, M. Beekman, B. Balke, G. Cerretti, W. Tremel, A. Zevalkink, A.I. Hofmann, C. Müller, B. Dörling, M. Campoy-Quiles, and M. Caironi, Thermoelectrics: from history: a window to the future. Mater: Sci. Eng. R (2019). https://doi.org/10.1016/j.mser.2018.09.001

X.F. Zheng, C.X. Liu, Y.Y. Yan, and Q. Wang, Renew. Sustain. Energy Rev. (2014). https://doi.org/10.1016/j.rser.2013.12.053

M. Zebarjadi, K. Esfarjani, M.S. Dresselhaus, Z.F. Ren, and G. Chen, Energy Environ. Sci. (2012). https://doi.org/10.1039/C1EE02497C

W. Shi, M. Gao, J. Wei, J. Gao, C. Fan, E. Ashalley, H. Li, and Z. Wang, Adv. Sci. (2018). https://doi.org/10.1002/advs.201700602

V.Q. Nguyen, J. Kim, and S. Cho, J. Korean Phys. Soc. (2018). https://doi.org/10.3938/jkps.72.841

R. Moshwan, L. Yang, J. Zou, and Z.-G. Chen, Adv. Funct. Mater. (2017). https://doi.org/10.1002/adfm.201703278

J.-Y. Cho, M. Siyar, W.C. **, E. Hwang, S.-H. Bae, S.-H. Hong, M. Kim, and C. Park, Mater. (2019). https://doi.org/10.3390/ma12233854

M. Hong, Z.-G. Chen, L. Yang, T.C. Chasapis, S.-D. Kang, Y. Zou, G.J. Auchterlonie, M.G. Kanatzidis, G.J. Snyder, and J. Zou, J. Mater. Chem. A (2017). https://doi.org/10.1039/C7TA02677C

H. Ju, D. Park, K. Kim, and J. Kim, Org. Electron. (2019). https://doi.org/10.1016/j.orgel.2019.05.017

S. Chen, K. Cai, and W. Zhao, Phys. B (2012). https://doi.org/10.1016/j.physb.2012.06.041

M. Terao, T. Nishida, Y. Miyauchi, T. Kaku, S. Horigome, and Y. Sugita, Jpn. J. Appl. Phys. (1989). https://doi.org/10.1143/JJAP.28.804

F. Abdel-Wahab, Physica (2011). https://doi.org/10.1016/j.physb.2010.09.048

H.-X. Mi, M.-X. Wu, S. Cao, Z.-Y. Huang, L. Han, and J. Xu, Effect of solder and barrier layer elements on the thermoelectric properties of Bi0.5Sb1.5Te3 (Mater: Res. Express, 2019). https://doi.org/10.1088/2053-1591/ab3cd5

G. Tan, M. Ohta, and M.G. Kanatzidis, Philos. Trans. R. Soc. A (2019). https://doi.org/10.1098/rsta.2018.0450

J. Yoon, S. Bae, H.-S. Sohn, I. Son, K. Kim, T. Kyung, and Y.-W. Ju, J. Nanosci. Nanotechnol. (2018). https://doi.org/10.1166/jnn.2018.15676

S.W. Chen, T.R. Yang, C.Y. Wu, H.W. Hsiao, H.S. Chu, J.D. Huang, and T.W. Liou, J. Alloys Compd. (2016). https://doi.org/10.1016/j.jallcom.2016.06.207

T.Y. Lin, C.N. Liao, and A.T. Wu, J. Electron. Mater. (2012). https://doi.org/10.1007/s11664-011-1740-8

H.-J. Wu, A.-T. Wu, P.-C. Wei, and S.-W. Chen, Mater. Res. Lett. 6, 244 (2018). https://doi.org/10.1080/21663831.2018.1436092

S.W. Chen, Z.W. Liu, H.S. Chu, and Z.Y. Huang, J. Alloys Compd. (2018). https://doi.org/10.1016/j.jallcom.2017.09.261

B. Predel, Ni-Se, Phase Equilibria (Springer, Berlin: Crystallographic and Thermodynamic Data of Binary Alloys, 1998).

S.W. Chen, Z.-W. Liu, H.S. Chu, and Z.Y. Huang, J. Alloys Compd. (2018). https://doi.org/10.1016/j.jallcom.2017.09.261

J. Liua, C. Guoa, C. Lia, and Z. Dua, Int. J. Mater. Res. (2013). https://doi.org/10.3139/146.110827

Y. Qiu, Y. Luo, X. Hu, Y. Li, and X. Jiang, Trans. Indian Inst. Met. (2019). https://doi.org/10.1007/s12666-018-1515-5

C.-M. Arvhult, C. Guéneau, S. Gossé, and M. Selleby, J. Mater. Sci. (2019). https://doi.org/10.1007/s10853-019-03689-0

S.-W. Chen, T.-R. Yang, H.-W. Hsiao, P.-H. Lin, J.-H. Huang, and J.-D. Huang, Mater. Chem. Phys. (2016). https://doi.org/10.1016/j.matchemphys.2016.06.023

Y. Feutelais, M. Majid, B. Legendre, and S.G. Fries, J. Phase Equilib. (1996). https://doi.org/10.1007/BF02648368

G. Ghosh, H.L. Lukas, and L. Delaey, Calphad (1988). https://doi.org/10.1016/0364-5916(88)90010-7

Y. Liu, D. Liang, and L. Zhang, J. Electron. Mater. (2010). https://doi.org/10.1007/s11664-009-0985-y

S.-W. Chen, and C.-N. Chiu, Scr. Mater. (2007). https://doi.org/10.1016/j.scriptamat.2006.09.018

A.I. Baranov, A.A. Isaeva, L. Kloo, V.A. Kulbachinskii, R.A. Lunin, V.N. Nikiforov, and B.A. Popovkin, J. Solid State Chem. (2004). https://doi.org/10.1016/j.jssc.2004.05.061

International Centre for Diffraction Data Powder Diffraction FileTM: SnSe (PDF# 48-1224).

E. Røst, and E. Vestersjø, Acta Chem. Scand. (1968). https://doi.org/10.3891/acta.chem.scand.22-2118

A.L.N. Stevels, and F. Jellinek, Monatsh. Chem. (1971). https://doi.org/10.1007/BF00905641

I. Jandal, F. Boero, H. Ipser, and K.W. Richer, Intermetallics (2014). https://doi.org/10.1016/j.intermet.2013.11.018

International Centre for Diffraction Data Powder Diffraction FileTM: SnTe (PDF# 46-1210).

Acknowledgments

The authors acknowledge the financial support of Ministry of Science and Technology, Taiwan (MOST-107-2923-E-007 -005 -MY3).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Musa, A.F., Chen, Sw. Interfacial Reactions in Ni/Se-Sn, Ni/Se-Te, Ni/Sn-Te and Ni/Se-Sn-Te Couples. Journal of Elec Materi 50, 4346–4357 (2021). https://doi.org/10.1007/s11664-021-08843-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11664-021-08843-6