Abstract

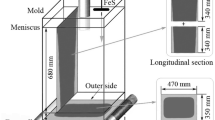

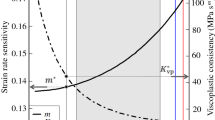

Non-uniform solidification of shell in continuous casting mold is the main cause of the high incidence of surface cracks of ultra-large beam blank (ULBB). To investigate the behaviors of the shell non-uniform heat transfer and its micro-structure growth, a thermomechanical model (TMM) of shell solidification in mold with the consideration of the mold flux and air gap dynamically filling in the shell-mold interface and a cellular automata-finite element (CAFE) model to describe the micro-structure growth of the shell were developed. In the models, the interfacial heat flux between the ULBB surface and mold calculated from the TMM was loaded on the CAFE model, and therefore, the cross-scale simulation of the shell solidification and the micro-structure growth were coupled. The results show that the air gap would not form at the positions of the web, fillet, and the center area of narrow face of the ULBB during the whole solidification in the mold. The thick air gap forms and concentrates in the flange tip, inner and outer corners of the flange as well as theirs surrounding areas. The thick mold flux mainly distributes in the areas of the flange outer corner, and the flange tip and the narrow face that are 0 to 45 mm and 0 to 31 mm away from the two edges of the flange outer corner. The maximum thicknesses of the air gap and mold flux appear at the positions of the inner and outer corners of the flange to the joints of the flange tip at the mold exit, which are about 0.75 mm and 0.99 mm, respectively. The maximum differences of the thickness of air gap and mold flux along the circumference of the mold are about 0.75 mm and 0.67 mm at the mold exit. The highest and lowest temperatures of the shell with a difference of 215 K appear at the flange tip and the flange inner corner. The maximum and minimum thickness of the shell appear at the center of the flange inner corner and the fillet of 617 mm from the center of the web, which are about 27.0 mm and 16.3 mm, with a difference of 10.7 mm. The maximum and minimum average grain sizes of the shell appear at the fillet and the flange inner corner, which are about 507.1 μm and 474.5 μm, with a difference of 32.6 μm.

Similar content being viewed by others

References

J.K. Park, I.V. Samarasekera, B.G. Thomas, and U.S. Yoon: Metall. Mater. Trans. B, 2002, vol. 33, pp. 425–36.

J. Wei, X. Wang, L. Cai, and M. Yao: Metall. Mater. Trans. B, 2022, vol. 53, pp. 1–11.

Z. Cai and M. Zhu: Int. J. Min. Metall. Mater., 2014, vol. 21, pp. 240–50.

Z. Cai and M. Zhu: ISIJ Int., 2013, vol. 53, pp. 1818–27.

Y. Meng and B.G. Thomas: Metall. Mater. Trans. B, 2003, vol. 34B, pp. 685–705.

C. Li and B.G. Thomas: Metall. Mater. Trans. B, 2004, vol. 35, pp. 1151–72.

Z. Cai and M. Zhu: Acta Metall. Sin., 2011, vol. 47, pp. 671–77.

Z. Cai and M. Zhu: Acta Metall. Sin., 2011, vol. 47, pp. 678–87.

R. Saraswat, D.M. Maijer, P.D. Lee, and K.C. Mills: ISIJ Int., 2007, vol. 47, pp. 95–104.

M. Rappaz and C.A. Gandin: Acta Metall. Mater., 1993, vol. 41, pp. 345–60.

C.A. Gandin and M. Rappaz: Acta Metall. Mater., 1994, vol. 42, pp. 2233–246.

L. Nastac and D.M. Stefanescu: Model. Simul. Mater. Sci. Eng., 1997, vol. 5, p. 391.

L. Nastac: Acta Mater., 1999, vol. 47, pp. 4253–62.

M. Zhu and C. Hong: ISIJ Int., 2001, vol. 41, pp. 436–45.

Z. Hou, F. Jiang, and G. Cheng: ISIJ Int., 2012, vol. 52, pp. 1301–09.

Y. Luo, J. Zhang, X. Wei, C. **ao, Z. Hu, Y. Yuan, and S. Chen: Ironmak. Steelmak., 2012, vol. 39, pp. 26–30.

MSC Marc: Theory and User Information, MSC Software Corporation, Newport Beach, 2016.

Z. Niu, Z. Cai, and M. Zhu: Metall. Mater. Trans. B, 2021, vol. 52, pp. 1556–73.

H. Nakada, M. Susa, Y. Seko, M. Hayashi, and K. Nagata: ISIJ Int., 2008, vol. 48, pp. 446–53.

A. Yamauchi, T. Emi, and S. Seetharaman: ISIJ Int., 2002, vol. 42, pp. 1084–093.

H. Xu, G. Wen, W. Sun, K. Wang, B. Yan, and W. Luo: Ironmak. Steelmak., 2010, vol. 37, pp. 380–86.

P.F. Kozlowski, B.G. Thomas, J.A. Azzi, and H. Wang: Metall. Trans. A, 1992, vol. 23, pp. 903–18.

H.N. Han, J.E. Lee, T. Yeo, Y.M. Won, K. Kim, K.H. Oh, and J.K. Yoon: ISIJ Int., 1999, vol. 39, pp. 445–54.

H. Mizukami, K. Murakami, and Y. Miyashita: Tetsu-to-Hagane, 1977, vol. 63, p. 652.

M. Uehara, I.V. Samarasekera, and J.K. Brimacombe: Ironmak. Steelmak., 1986, vol. 13, pp. 138–53.

P. Xu, S. Wang, Y. Zhou, D. Chen, M. Long, and H. Duan: Front. Mater., 2022, vol. 9, p. 841961.

X. Liu and M. Zhu: ISIJ Int., 2006, vol. 46, pp. 1652–659.

D.M. Stefanescu: ISIJ Int., 1995, vol. 35, pp. 637–50.

W. Kurz, B. Giovanola, and R. Trivedi: Acta Metall., 1986, vol. 34, pp. 823–30.

W. Kurz and D.J. Fisher: Fundaments of Solidification, 4th ed. Trans Tech Publishers, Aedermannsdorf, 1998, p. 77.

Acknowledgment

The present study was supported by the National Key Research and Development Program (2021YFB3401001), Liao Ning Revitalization Talents Program (XLYC2203196), and Fundamental Research Funds for the Central Universities of China (N2425008). The authors greatly appreciate their support.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

No potential conflict of interest was reported by the authors.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Wang, Sb., Cai, Zz. & Zhu, My. Non-uniform Solidification Behavior of Shell in Ultra-Large Beam Blank Mold. Metall Mater Trans B (2024). https://doi.org/10.1007/s11663-024-03169-0

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s11663-024-03169-0