Abstract

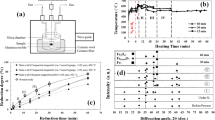

The microstructure mechanism and kinetics of magnetite powder reduction in the H2 atmosphere were studied by both microwave heating and conventional heating methods. Cross-sectional morphologies of the reduction products obtained through these two heating methods were compared. In both cases, the reduction occurred layer by layer and with the formation of irregular pores in the iron layer. The difference between the two methods was the occurrence of cracks in the particles during conventional heating. The macroscopic kinetics of magnetite reduction was analyzed by measuring the water content with a hygrometer. In a reducing atmosphere comprising 60 pct H2-Ar at 1173–1373 K, the reduction of magnetite took place in two stages: from Fe3O4 to FeO and from FeO to Fe. Microwave radiation increased the atomic diffusion coefficient, thereby enhancing diffusion and reaction rate. The reduction rate at 1173 K under microwave was nearly equal to that of 1373 K under conventional conditions, despite a temperature difference of 200 K. Compared to conventional heating, microwave heating reduced the reaction activation energy.

Similar content being viewed by others

References

P. **, Z.Y. Jiang, and C. Bao: Steel Res. Int., 2015, vol. 37(4), pp. 499–508. https://doi.org/10.1002/srin.201500054.

K. He, Z. Zheng, and Z. Chen: Int J Hydrogen Energ, 2021, vol. 46(5), pp. 4592–4605. https://doi.org/10.1016/j.ijhydene.2020.10.263.

A. Pineau, N. Kanari, and I. Gaballah: Thermochim Acta, 2007, vol. 456(2), pp. 75–88. https://doi.org/10.1016/j.tca.2007.01.014.

K.C. Sabat and R.K. Paramguru: Plasma Chem Plasma Process, 2014, vol. 34(1), pp. 1–23. https://doi.org/10.1007/s11090-013-9484-2.

P. Rajput, K.C. Sabat, et al.: Ironmak & Steelmak, 2014, vol. 41(10), pp. 721–31. https://doi.org/10.1179/1743281214Y.0000000186.

H.Y. Sohn and M. Olivas-Martinez: JOM, 2014, vol. 66(9), pp. 1557–64. https://doi.org/10.1007/s11837-014-1120-y.

W. Liu, J.Y. Lim, M.A. Saudedu, A.N. Hayhurst, S.A. Scott, and J.S. Dennis: Chem. Eng. Sci., 2014, vol. 120, pp. 149–66. https://doi.org/10.1016/j.ces.2014.08.010.

M. Elzohiery, H.Y. Sohn, and Y. Mohassab: Steel Res Int, 2017, vol. 88(2), p. 1600133. https://doi.org/10.1002/srin.201600133.

A. Ferrari, J. Hunt, A. Lita, B. Ashley, and A.E. Stiegman: Indian J Chem A, 2014, vol. 118(18), pp. 9346–56. https://doi.org/10.1021/jp501206n.

J. Hunt, A. Ferrari, A. Lita, M. Crosswhite, B. Ashley, and A.E. Stiegman: Indian J Chem A, 2013, vol. 117, pp. 26871–80. https://doi.org/10.1021/jp4076965.

J. Zhou, W. Xu, Z. You, Z. Wang, Y. Luo, and L. Gao: Sci Rep, 2016, vol. 6, p. 25149. https://doi.org/10.1038/srep25149.

H. Hinrikus, J. Lass, and D. Karai: Electromagn. Biol. Med., 2015, vol. 34(4), pp. 327–33. https://doi.org/10.3109/15368378.2014.921195.

S.I. Ayvaz and I. Aydin: Trans Indian I Metals, 2020, vol. 73(10), pp. 2635–44. https://doi.org/10.1007/s12666-020-02072-x.

M.A. Janney, H.D. Kimrey, and W.R. Allen: J. Mater. Sci., 1997, vol. 32(5), pp. 1347–55.

P.K. Loharkar, A. Ingle, and S. Jhavar: J Mater Res Technol, 2019, vol. 8(3), pp. 3306–26. https://doi.org/10.1016/j.jmrt.2019.04.004.

D.J. Skamser and D.L. Johnson: MRS Online Proc Library (OPL)., 1994, vol. 347, pp. 325–30. https://doi.org/10.1557/PROC-347-325.

J.G.P. Binner and I.A.H. Al-Dawery: Supercond Sci Tech, 1998, vol. 11(11), pp. 1230–6. https://doi.org/10.1088/0953-2048/11/11/006.

J. Chen, L. Liu, and J.Q. Zeng: Steel., 2004, vol. 39(6), pp. 1–5.

N. Standish and H. Worncr: J Microwave Power EE, 1990, vol. 25(3), pp. 177–9. https://doi.org/10.1080/08327823.1990.11688126.

Y.X. Hua and C.P. Liu: Acta Metall Sinical (English Lett)., 1996, vol. 9(3), pp. 164–5.

N.A. Hassine: Int J Refrac Metals Hard Mater, 1995, vol. 6, pp. 353–8. https://doi.org/10.1016/0263-4368(95)00035-H.

A.B. Yu, N. Standish, R.P. Zou: 6th AusMM Extractive Metallurgy Conference Metall. (1994), pp. 225-32.

W.L.E. Wong, S. Karthik, and M. Gupta: J. Mater. Sci., 2005, vol. 40, pp. 3395–402. https://doi.org/10.1007/s10853-005-0419-z.

K. Kashimura, M. Sato, M. Hotta, D. Kumar, K. Agrawal, and M. Nagata: Mater. Sci. Eng. A, 2012, vol. 556, pp. 977–9. https://doi.org/10.1016/j.msea.2012.07.049.

S. Agrawal and N. Dhawan: J Sustain Metall, 2020, vol. 6, pp. 355–66. https://doi.org/10.1007/s40831-020-00279-2.

P.C. Harrison: Fundamental study of the heating effect of 2.45 GHz microwave radiation on minerals, University of Birmingham, 1997.

S. Zhong and H.E. Geotzman: Mining Metall Explor, 1996, vol. 13, pp. 174–8. https://doi.org/10.1007/BF03402742.

A. Amini, K. Ohno, T. Maeda, and K. Kunitomo: Chem. Eng. J., 2019, vol. 374, pp. 648–57. https://doi.org/10.1016/j.cej.2019.05.226.

Y. Mohassab and H.Y. Sohn: Steel Res. Int., 2015, vol. 86(7), pp. 740–52. https://doi.org/10.1002/srin.201400186.

C.J. Sun, L.Q. Ai, L.K. Hong, and Y.Q. Li: Ironmak Steelmak., 2019, vol. 47, pp. 1015–21. https://doi.org/10.1080/03019233.2019.1659657.

J. Pang, P. Guo, and Z. Pei: J. Iron. Steel Res. Int., 2009, vol. 16(5), pp. 07–11. https://doi.org/10.1016/S1006-706X(10)60002-7.

S.H. Kim, X. Zhang, and Y. Ma: Acta Mater., 2021, vol. 212, 116933https://doi.org/10.1016/j.actamat.2021.116933.

B. Abolpoura, M.M. Afsahia, and M. Azizkarimi: Miner Process Extr M, 2018, vol. 127(1), pp. 29–39. https://doi.org/10.1080/03719553.2016.1277094.

M. Stir, K. Ishizaki, S. Vaucher, and R. Nicula: J. Appl. Phys., 2009, vol. 105(12), p. 124901. https://doi.org/10.1063/1.3148264.

B. Janković: Chem. Eng. J., 2008, vol. 139(1), pp. 128–35. https://doi.org/10.1016/j.cej.2007.07.085.

A.A. Barde, J.F. Klausner, and R. Mei: Int J Hydrogen Energ, 2016, vol. 41(24), pp. 10103–19. https://doi.org/10.1016/j.ijhydene.2015.12.129.

J.D. Hancock and J.H. Sharp: J Am Ceram Soc, 1972, vol. 55(2), pp. 74–7. https://doi.org/10.1111/J.1151-2916.1972.TB11213.X.

X.Y. Hua: Acta Metall Sin, 2023, https://doi.org/10.1016/j.jallcom.2005.0.4.009.

G. Martin and P. Bellon: Adv. Res. App., 1996, vol. 50, pp. 189–331. https://doi.org/10.1016/S0081-1947(08)60605-0.

S.K. Kuila, R. Chatterjee, and D. Ghosh: Int J Hydrogen Energy, 2016, vol. 41(22), pp. 9256–66. https://doi.org/10.1016/j.ijhydene.2016.04.075.

Funding

This study was supported by the Natural science foundation of Hebei Province (E2021209101; E2022209112); Science and Technology Research Projects of Higher Education Institutions in Hebei Province (ZD2022125); Tangshan Talent funding Project (A20220212)

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

On behalf of all authors, the corresponding author states that there is no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Zhou, M., Ai, L., Hong, L. et al. Comparison Between Microwave Heating and Conventional Heating of Magnetite During Hydrogen Reduction. Metall Mater Trans B 55, 114–127 (2024). https://doi.org/10.1007/s11663-023-02944-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11663-023-02944-9