Abstract

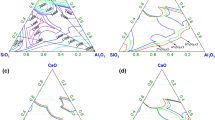

Desulfurization of molten iron by molten slag is an electrochemical reaction. Previous investigations confirmed that applying electricity could enhance the desulfurization of molten iron, but a quantitative relation between the electricity and the desulfurization was not fully elucidated. The present study attempted to correlate the extent of the electrochemical desulfurization with the applied electricity via a series of high-temperature desulfurization experiments and thermodynamic analyses. A molten iron containing C and S was allowed to react with CaO–\(\hbox {Al}_{{2}}\hbox {O}_{{3}}\)–\(\hbox {MgO}_{\text {sat.}}\) slag at 1673 K (1400 \(^\circ \)C), with and without the electricity of constant current. S distribution coefficients (\(L_{\text {S}}\) = (pct S)/[pct S]) were obtained after the normal and the electrochemical equilibria, respectively. The obtained results were interpreted by employing the Nernst equation in order to extract the potential difference (\(\varDelta \phi _{\text {S}}\)) for the electrochemical desulfurization. It was found that applying electric current (I) increased the \(L_{\text {S}}\) after the electrochemical desulfurization, which resulted in the increase of \(\varDelta \phi _{\text {S}}\). A resistance, \(R_{\text {DeS}} = \varDelta \phi _{\text {S}}\)/I, or a specific resistivity, \(\rho _{\text {DeS}} = \varDelta \phi _{\text {S}}\)/(I/A), where A is the cathodic area, for the electrochemical desulfurization was defined, which can be used to characterize the susceptibility to the electrochemical desulfurization. It was found that \(R_{\text {DeS}}\) was independent of the I within the range of this investigation, decreased as (pct CaO)/(pct \(\hbox {Al}_{{2}}\hbox {O}_{{3}}\)) increased and was proportional to the resistance of the slag (\(R_{\text {slag}}\)). A favorable condition for the electrochemical desulfurization is not the same as that for the normal desulfurization condition. The \(\varDelta \phi _{\text {S}}\), which is an indicator of the extent of electrochemical desulfurization, was independently predicted by employing a thermodynamic model for the oxysulfide slag. The model prediction was in a good agreement with the experimental data. The model was used to predict necessary current level for a desired electrochemical desulfurization.

Similar content being viewed by others

References

G. Derge, W.O. Philbrook, and K.M. Goldman: JOM, 1950, vol. 2, pp. 1111-19.

S. Ramachandran, T.B. King, and N.J. Grant: JOM, 1956, vol. 8, pp. 1549–88.

T.B. King and S. Ramachandran: in Physical Chemistry of Steelmaking, J.F. Elliott, ed., Wiley, New York, 1958, pp. 125–35.

M. Tokuda and M. Ohtani: in Chemical Metallurgy of Iron and Steel, B.B. Argent and M. Davies, eds., Unwin Brothers Ltd., Surrey, 1973, pp. 93–95.

M.G. Frohberg, M.L. Kapoor, and A. Nilas: in Chemical Metallurgy of Iron and Steel, B.B. Argent and M. Davies, eds., Unwin Brothers Ltd., Surrey, 1973, pp. 139–43.

J.R. Wynnyckyj and S. Roy: Can. Metall. Quart., 1973, vol. 12, pp. 303-07.

M. Ohtani, and N.A. Gokcen: in Physical Chemistry of Process Metallurgy, G. St Pierre, ed. Interscience, New York, 1961, pp. 1213–27.

R.G. Ward and K.A. Salmon: J. Iron Steel Inst., 1963, vol. 201,pp. 222–27.

P.M. Bills and R. Littlewood: J. Iron Steel Inst., 1965, vol. 203, pp. 181–82.

T. El-Gammal, B. Yostos, and A. Pakzad: in Chemical Metallurgy of Iron and Steel, B.B. Argent and M. Davies, eds., Unwin Brothers Ltd., Surrey, 1973, pp. 144–47.

A. McLean, I.D. Sommerville, and F.L. Kemeny: Proc. 4th Int. Conf. Molten Slags Fluxes, ed. S. Ban-ya, 1992, pp. 268–73.

I.D. Sommerville, M. Mishea, and A. McLean: in 14th PTD Conference Proceedings, 1995, pp. 25–36.

N. Sen, M. Ghosh, U.K. Banerjee, S. Mazumdar, and H.S. Ray: Scan. J. Met., 1999, vol. 28, pp. 249–53.

D.-H. Kim, W. Kim, and Y.-B. Kang: Metall. Mater. Trans. B, 2018, vol. 49B, pp. 1311-21.

D.-H. Kim, W. Kim, and Y.-B. Kang: J. Electrochem. Soc., 2018, vol. 164, pp. E816-25.

H.L. Han, L.W. Zhou, K. Liu, Z.H. Lu, and N. Luo: Metalurgija, 2020, vol. 59, pp. 295-98.

S.H. Lee, D.J. Min, 236, 116231 (2020)

S.H. Lee and D.J. Min: Materials, 2020, vol. 13, p. 2478.

M.S. Islam, M.A. Rhamdhani, and G.A. Brooks: Metall. Mater. Trans. B, 2014, vol. 45B, pp. 1–5.

Z. Wang, Z. Ge, J. Liu, G. Qian and B. Du: Separation and Purification Technology, 2018, vol. 199, pp. 134-69.

M.A. Rhamdhani: Private Communication (Swinburne University of Technology, 2019)

M.A. Rhamdhani, K.S. Coley, and G.A. Brooks: Metall. Mater. Trans. B, 2005, vol. 36B, pp. 219–27.

M.A. Rhamdhani, K.S. Coley, and G.A. Brooks: Metall. Mater. Trans. B, 2006, vol. 37B, pp. 1087–91.

L. Chang and K.M. Goldman: Trans. AIME, 1948, vol. 176, pp. 309–29.

R.G. Ward and K.A. Salmon: J. Iron Steel Inst., 1963, vol. 201, pp. 222–27.

Y.-B. Kang and F. Tafwidli: ISIJ Int., 2018, vol. 58, pp. 10-16.

P.C. Hayes: Process Principles in Minerals & Materials Production. Hayes Publ. Co., Sherwood, QLD, Australia, 1993, p. 346.

K. Mori and Y. Matsushita: Tetsu-to-Hagane, 1952, vol. 38, pp. 531-36.

A.D. Pelton, P. Chartrand, and G. Eriksson: Metall. Mater. Trans. A, 2001, vol. 32A, pp. 1409-16.

P. Chartrand and A.D. Pelton: Metall. Mater. Trans. A, 2001, vol. 32A, pp.1361-83.

P. Chartrand and A.D. Pelton: Metall. Mater. Trans. A, 2001, vol. 32A, pp.1385-96.

P. Chartrand and A.D. Pelton: Metall. Mater. Trans. A, 2001, vol. 32A, pp.1417-30.

Y.-B. Kang and A. D. Pelton: Metall. Mater. Trans. B, 2009, vol. 40B, pp. 979-994.

Y.-B. Kang, Progress of Thermodynamic Modeling for Sulfide Dissolution in Molten Oxide Slags: Sulfide Capacity and Phase Diagram. Metall. Mater. Trans. B (2021). https://doi.org/10.1007/s11663-021-02224-4

C.W. Bale, E. Bélisle, P. Chartrand, S.A. Decterov, G. Eriksson, K. Hack, I.-H. Jung, Y.-B. Kang, J. Melançon, A.D. Pelton, C. Robelin, and S. Petersen: Calphad, 2009, vol. 33, pp. 295–311.

C.W. Bale, E. Bélisle, P. Chartrand, S.A. Decterov, G. Eriksson, A.E. Gheribi, K. Hack, I.-H. Jung, Y.-B. Kang, J. Melançon, A.D. Pelton, S. Petersen, C. Robelin, J. Sangster, P. Spencer, and M.-A. Van Ende: Calphad, 2016, vol. 54, pp. 35–53.

F. Tafwidli and Y.-B. Kang: ISIJ Int., 2017, vol. 57, pp. 782-90.

Acknowledgments

One of the authors (YBK) thanks Prof. M.A. Rhamdhani, Swinburne University of Technology, Australia, for his kind discussion on the electrochemical reaction.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Manuscript submitted March 29, 2021; accepted July 15, 2021.

Rights and permissions

About this article

Cite this article

Kim, DH., Kang, YB. An Attempt to Correlate Electrochemical Desulfurization of Molten Iron Using CaO–Al2O3–MgOsat. Molten Slag and Applied Electricity at 1673 K (1400 °C). Metall Mater Trans B 52, 2960–2970 (2021). https://doi.org/10.1007/s11663-021-02289-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11663-021-02289-1