Abstract

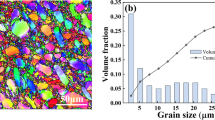

In this study, the solidification microstructure, reconstructed by the method of parent grain crystallographic reconstruction (PGCR), was studied for TC4 titanium alloy welded joint. The investigation focused on the impact of the solidification microstructure on the phase transformation process and grain boundary transformation mechanism in various regions of the welded joint. Additionally, the study explored the influence of phase transformation and grain boundary transformation on the mechanical properties of the joint. The results showed that the microstructure of fusion zone (FZ) and heat affected zone (HAZ) in the joint was transformed from equiaxed primary α and α + β lamellae to complete primary β grains, and then α' phase was precipitated in the primary β grain, and the residual phases were transformed into secondary α phases. The transformation process from β to α' was controlled by the Burgers orientation relationship (OR), mainly from the primary β of {101}{111} crystal plane groups to the α' and α phases of {1000} {11-20} crystal plane groups. The sizes of primary β and α1' phase were both increased with the rise in heat absorption in different regions, and the tensile strength of the joint was at a considerable level than that of the Base, reaching 100.87 pct. Due to the increase of dislocation density and the quantities of high angle grain boundary, the impact energy of the joint reached 31.19 J, which was larger than the 18.51 J of the Base.

Similar content being viewed by others

References

Q. Zhao, Q. Sun, S. **n, Y. Chen, Wu. Cong, H. Wang, Xu. Jianwei, M. Wan, W. Zeng, and Y. Zhao: Mater. Sci. Eng. A, 2022, vol. 845, p. 143260. https://doi.org/10.1016/j.msea.2022.143260.

X.-L. Gao, L.-J. Zhang, J. Liu, and J.-X. Zhang: Mater. Sci. Eng. A, 2013, vol. 559, pp. 14–21. https://doi.org/10.1016/j.msea.2012.06.016.

Bu. Hengchang, Q. Gao, Y. Li, F. Wang, and X. Zhan: Met. Mater. Int., 2021, vol. 27, pp. 3449–61. https://doi.org/10.1007/s12540-020-00683-z.

N. Li, T. Wang, S. Jiang, and L. Zhang: Mater Charact, 2021, vol. 178, p. 111275. https://doi.org/10.1016/j.matchar.2021.111275.

Lu. Wei, X. Li, Y. Lei, and Y. Shi: Mater. Sci. Eng. A, 2012, vol. 540, pp. 135–41. https://doi.org/10.1016/j.msea.2012.01.117.

S. Lathabai, B.L. Jarvis, and K.J. Barton: Mater. Sci. Eng. A, 2001, vol. 299, pp. 81–93. https://doi.org/10.1016/S0921-5093(00)01408-8.

Ou. Peng, Z. Cao, M. Hai, J. Qiang, Y. Wang, J. Wang, G. Zheng, and J. Zhang: Mater Charact, 2023, vol. 196, p. 112644. https://doi.org/10.1016/j.matchar.2023.112644.

S. Cui, Y. Shi, T. Zhu, and W. Liu: J. Manuf. Process., 2019, vol. 37, pp. 418–24. https://doi.org/10.1016/j.jmapro.2018.12.022.

L. Germain, N. Gey, R. Mercier, P. Blaineau, and M. Humbert: Acta Mater., 2012, vol. 60, pp. 4551–62. https://doi.org/10.1016/j.actamat.2012.04.034.

M. Abbasi, M. Dehghani, H.-U. Guim, and D.-I. Kim: Acta Mater., 2016, vol. 117, pp. 262–69. https://doi.org/10.1016/j.actamat.2016.06.064.

N. Stanford and P.S. Bate: Acta Mater., 2004, vol. 52, pp. 5215–24. https://doi.org/10.1016/j.actamat.2004.07.034.

R. Hielscher, T. Nyyssönen, F. Niessen, and A.A. Gazder: Materialia, 2022, vol. 22, p. 101399. https://doi.org/10.1016/j.mtla.2022.101399.

H. Beladi, Qi. Chao, and G.S. Rohrer: Acta Mater., 2014, vol. 80, pp. 478–89. https://doi.org/10.1016/j.actamat.2014.06.064.

D. Sun, Z. Zhou, K. Zhang, X. Yang, X. Liu, Z. Guo, and Gu. Jianfeng: Mater. Des., 2023, vol. 227, p. 111692. https://doi.org/10.1016/j.matdes.2023.111692.

Lu. Yang, S. Ramachandran, A. Bagasol, Q. Guan, W. Wang, D.J. Browne, D. Dowling, and W. Mirihanage: Scripta Mater., 2023, vol. 231, p. 115430. https://doi.org/10.1016/j.scriptamat.2023.115430.

M. Esmaily, S.N. Mortazavi, P. Todehfalah, and M. Rashidi: Mater. Des., 2013, vol. 47, pp. 143–50. https://doi.org/10.1016/j.matdes.2012.12.024.

G.J. Tchein, D. Jacquin, D. Coupard, E. Lacoste, and F.G. Mata: Metall. Mater. Trans. A, 2018, vol. 49A, pp. 2113–23. https://doi.org/10.1007/s11661-018-4568-5.

L. Wang, C. Shen, Y. Zhang, F. Li, W. Zhou, J. **n, Y. Ding, and X. Hua: Mater. Sci. Eng. A, 2022, vol. 856, p. 144028. https://doi.org/10.1016/j.msea.2022.144028.

T. Lin, L. Zhou, Xu. **wei, Y. Guo, H. Luo, Z. Cai, H. Wang, J. Li, Y. Liang, and Yu. Liang: Mater. Des., 2023, vol. 230, p. 111972. https://doi.org/10.1016/j.matdes.2023.111972.

J.-D. Kim: Mater Charact, 2021, vol. 178, p. 111300. https://doi.org/10.1016/j.matchar.2021.111300.

B. Vrancken, L. Thijs, J.-P. Kruth, and J. Van Humbeeck: J. Alloys Compd., 2012, vol. 541, pp. 177–85. https://doi.org/10.1016/j.jallcom.2012.07.022.

S.D. Meshram and T. Mohandas: Mater. Des., 2010, vol. 31, pp. 2245–52. https://doi.org/10.1016/j.matdes.2009.10.012.

X. Li, Q. Zhu, S. Liu, C. Wang, F. Li, F. Chen, L. Feng, H. Wang, J. Cheng, and H. Chang: Mater. Sci. Technol., 2022, vol. 38, pp. 1543–53. https://doi.org/10.1080/02670836.2022.2090668.

F.R. Kaschel, R.K. Vijayaraghavan, A. Shmeliov, E.K. McCarthy, M. Canavan, P.J. McNally, D.P. Dowling, V. Nicolosi, and M. Celikin: Acta Mater., 2020, vol. 188, pp. 720–32. https://doi.org/10.1016/j.actamat.2020.02.056.

Lu. Yu, R. Turner, J. Brooks, and H. Basoalto: J. Mater. Sci. Technol., 2022, vol. 113, pp. 117–27. https://doi.org/10.1016/j.jmst.2021.10.023.

H.M. Hamza, K.M. Deen, and W. Haider: Mater. Sci. Eng. C, 2020, vol. 113, p. 110980. https://doi.org/10.1016/j.msec.2020.110980.

M. Shahsavari: J. Appl. Electrochem., 2022, vol. 52, pp. 1003–19. https://doi.org/10.1007/s10800-022-01683-0.

J. Yang, Yu. Hanchen, J. Yin, M. Gao, Z. Wang, and X. Zeng: Mater. Des., 2016, vol. 108, pp. 308–18. https://doi.org/10.1016/j.matdes.2016.06.117.

N. Yumak and K. Aslantaş: J. Market. Res., 2020, vol. 9, pp. 15360–80. https://doi.org/10.1016/j.jmrt.2020.10.088.

S. Pal, G. Lojen, V. Kokol, and I. Drstvensek: J. Manuf. Process., 2018, vol. 35, pp. 538–46. https://doi.org/10.1016/j.jmapro.2018.09.012.

X. Tan and Y. Kok: Acta Mater., 2015, vol. 97, pp. 1–6. https://doi.org/10.1016/j.actamat.2015.06.036.

W.G. Burgers: Physica, 1934, vol. 1, pp. 561–86. https://doi.org/10.1016/S0031-8914(34)80244-3.

S. Mironov, Y. Zhang, Y.S. Sato, and H. Kokawa: Scripta Mater., 2008, vol. 59, pp. 511–14. https://doi.org/10.1016/j.scriptamat.2008.04.038.

A.I. Saville, B. Ellyson, A. Eres-Castellanos, J.T. Benzing, and A.J. Clarke: Scripta Mater., 2023, vol. 226, p. 115248. https://doi.org/10.1016/j.scriptamat.2022.115248.

A. Bardelcik, C.P. Salisbury, S. Winkler, M.A. Wells, and M.J. Worswick: Int. J. Impact Eng, 2010, vol. 37, pp. 694–702. https://doi.org/10.1016/j.ijimpeng.2009.05.009.

T. Ahmed and H.J. Rack: Mater. Sci. Eng. A, 1998, vol. 243, pp. 206–11. https://doi.org/10.1016/S0921-5093(97)00802-2.

H. Sun, Y. Liang, G. Li, X. Zhang, S. Wang, and C. Huang: J. Alloys Compd., 2021, vol. 868, p. 159155. https://doi.org/10.1016/j.jallcom.2021.159155.

P. Nath, L. Marandi, and I. Sen: J. Alloys Compd., 2022, vol. 927, p. 167039. https://doi.org/10.1016/j.jallcom.2022.167039.

J. Šmilauerová, P. Harcuba, J. Stráská, J. Stráský, M. Janeček, J. Pospíšil, J. Ilavský, and V. Holý: Mater Charact, 2023, vol. 196, p. 112615. https://doi.org/10.1016/j.matchar.2022.112615.

J. Zhang, Xu. Dong, X. Wang, J. Zhao, H. He, and Q. Yang: Measurement, 2023, vol. 211, p. 112670. https://doi.org/10.1016/j.measurement.2023.112670.

S. Mironov, Y.S. Sato, H. Kokawa, S. Hirano, A.L. Pilchak, and S.L. Semiatin: Metals, 2020, https://doi.org/10.3390/met10070976.

P. Kwasniak, H. Garbacz, and K.J. Kurzydlowski: Acta Mater., 2016, vol. 102, pp. 304–14. https://doi.org/10.1016/j.actamat.2015.09.041.

G.M. Ter Haar and T.H. Becker: Materials, 2018, https://doi.org/10.3390/ma11010146.

S. Wroński, J. Tarasiuk, B. Bacroix, A. Baczmański, and C. Braham: Materials, 2012, vol. 73, pp. 52–60. https://doi.org/10.1016/j.matchar.2012.07.016.

S.-W. Cui, Y.-H. Shi, and C.-S. Zhang: Trans. Nonferrous Met. Soc. China, 2021, vol. 31, pp. 416–25. https://doi.org/10.1016/S1003-6326(21)65506-1.

Acknowledgments

This research was supported by Jiangsu Province Science and Technology Achievement Transformation Fund (BA2020068), Zhejiang Key Project of Research and Development Plan (2021C01085), Key Technology Research Project of Beilun District Ningbo City (2021BLG005), and National Natural Science Foundation of China (52005320).

Author information

Authors and Affiliations

Contributions

**hong Du contributed toward conceptualization, investigation, data curation, and writing– original draft. Hongbing Liu contributed toward funding acquisition, writing – review & editing, and supervision. Fei Wang contributed toward writing -review & editing, supervision, and conceptualization. Wen Bao contributed toward writing – review & editing. Huan Li contributed toward writing -review & editing, supervision, project administration, and funding acquisition.

Corresponding authors

Ethics declarations

Competing interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Du, J., Liu, H., Wang, F. et al. Solidification Microstructure Reconstruction and Its Effects on Phase Transformation, Grain Boundary Transformation Mechanism, and Mechanical Properties of TC4 Alloy Welded Joint. Metall Mater Trans A 55, 1193–1206 (2024). https://doi.org/10.1007/s11661-024-07317-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11661-024-07317-8