Abstract

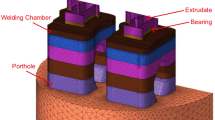

The industrial use of 6000-series Al alloys is increasing owing to their high formability and recyclability. Structural control of these alloys can be achieved based on the stress applied during extrusion to improve their mechanical properties and recyclability. In this study, three dies were fabricated with different mold lengths and taper angles. The results of finite element analysis (FEA) showed that the die with a short and straight mold had a smaller distribution of von Mises stresses (σvM) than other dies, measuring over 40 MPa around the section in contact with the mold-forming area. The FEA results of this extruded profile represented relative trends of the measured residual stress distribution effectively; i.e., the depth corresponding to the maximum σvM decreased with the processing stress in the dies. This profile showed improved bendability relative to the other dies owing to its thinner 〈110〉//extrusion direction surface layer and finer crystal grains. Improvements in mechanical properties based on the structural state could be predicted in advance using FEA owing to the correlation between the stress distributions simulated using FEA and the measured structural and stress distributions.

Similar content being viewed by others

References

W.S. Miller, L. Zhuang, J. Bottema, A.J. Wittebrood, P. De Smet, A. Haszler, and A. Vieregge: Mater. Sci. Eng. A, 2000, vol. 280, pp. 37–49. https://doi.org/10.1016/S0921-5093(99)00653-X.

J. Hirsch: Mater. Trans., 2011, vol. 52, pp. 818–24. https://doi.org/10.2320/matertrans.L-MZ201132.

Y. Liu, Y.X. Lai, Z.Q. Chen, S.L. Chen, P. Gao, and J.H. Chen: J. Alloys Compd., 2021, vol. 885, p. 160942. https://doi.org/10.1016/j.jallcom.2021.160942.

G. Mao, G. Tong, W. Gao, S. Liu, and L. Zhong: Mater. Lett., 2021, vol. 302, p. 130428. https://doi.org/10.1016/j.matlet.2021.130428.

J. Nakamura, K. Matsuda, T. Kawabata, T. Sato, Y. Nakamura, and S. Ikeno: Mater. Trans., 2010, vol. 51, pp. 310–16. https://doi.org/10.2320/matertrans.MC200911.

Y. Koshino, M. Kozuka, S. Hirosawa, and Y. Aruga: J. Alloys Compd., 2015, vol. 622, pp. 765–70. https://doi.org/10.1016/j.jallcom.2014.10.199.

E.A. Mørtsell, C.D. Marioara, S.J. Andersen, I.G. Ringdalen, J. Friis, S. Wenner, J. Røyset, O. Reiso, and R. Holmestad: J. Alloys Compd., 2017, vol. 699, pp. 235–42. https://doi.org/10.1016/j.jallcom.2016.12.273.

T. Watari, K. Nansai, and K. Nakajima: Resour. Conserv. Recycl., 2021, vol. 164, p. 105107. https://doi.org/10.1016/j.resconrec.2020.105107.

K. Nakajima, O. Takeda, T. Miki, K. Matsubae, S. Nakamura, and T. Nagasaka: Environ. Sci. Technol., 2010, vol. 44, pp. 5594–5600. https://doi.org/10.1021/es9038769.

T. Hiraki and T. Nagasaka: J. Mater. Cycles Waste Manag., 2015, vol. 17, pp. 566–73. https://doi.org/10.1007/s10163-014-0283-5.

S. Wronski and B. Bacroix: Acta Mater., 2014, vol. 76, pp. 404–12. https://doi.org/10.1016/j.actamat.2014.05.034.

H. Utsunomiya, T. Ueno, and T. Sakai: Scr. Mater., 2007, vol. 57, pp. 1109–12. https://doi.org/10.1016/j.scriptamat.2007.08.024.

T. Obata, Y. Tang, H. Iwaoka, S. Hirosawa, K. Mouri, and M. Shimoda: Keikinzoku/J. Jpn. Inst. Light Met., 2018, vol. 68, pp. 65–72. https://doi.org/10.2464/jilm.68.65.

J. Huot: Appl. Sci. Technol., 2016, pp. 19–26. https://doi.org/10.1007/978-3-319-35107-0_5.

K. Zhang, K. Marthinsen, B. Holmedal, T. Aukrust, and A. Segatori: Mater. Sci. Eng. A, 2018, vol. 722, pp. 20–29. https://doi.org/10.1016/j.msea.2018.02.081.

H. Inoue: Keikinzoku/J. Jpn. Inst. Light Met., 2002, vol. 52, pp. 524–29. https://doi.org/10.2464/jilm.52.524.

K.V. Gow and R.W. Cahn: Acta Metall., 1953, vol. 1, pp. 238–41. https://doi.org/10.1016/0001-6160(53)90066-2.

S. Kaneko, K. Murakami, and T. Sakai: Mater. Sci. Eng. A, 2009, vol. 500, pp. 8–15. https://doi.org/10.1016/j.msea.2008.09.057.

S. Oda and S.-I. Tanaka: IOP Conf. Ser., 2021, vol. 1121, p. 012042. https://doi.org/10.1088/1757-899x/1121/1/012042.

S. Oda and S.-I. Tanaka: Mater. Sci. Eng. A, 2022, vol. 829, p. 142167. https://doi.org/10.1016/j.msea.2021.142167.

S. Oda and S.-I. Tanaka: Mater. Sci. Eng. A, 2022, vol. 834, p. 142630. https://doi.org/10.1016/j.msea.2022.142630.

B. Reggiani, A. Segatori, L. Donati, and L. Tomesani: Int. J. Adv. Manuf. Technol., 2013, vol. 69, pp. 1855–72. https://doi.org/10.1007/s00170-013-5143-2.

C.M. Sellars and W.J.M. Tegart: Int. Metall. Rev., 1972, vol. 17, pp. 1–24. https://doi.org/10.1179/imtlr.1972.17.1.1.

S. Taira and K. Tanaka: Trans. Iron Steel Inst. Jpn., 1979, vol. 19, pp. 411–18. https://doi.org/10.2355/isi**ternational1966.19.411.

T. Sasaki, Y. Hirose, K. Sasaki, and Yasukawa: Adv. X-Ray Anal., 1997, vol. 40. https://www.icdd.com/axa-login/?article=9464d39308f2c4.

T. Sasaki and Y. Hirose: J. Soc. Mater. Sci. Jpn., 1995, vol. 44, pp. 1138–43. https://doi.org/10.2472/jsms.44.1138.

S.-I. Tanaka: Bull. Jpn. Inst. Met., 1990, vol. 29, pp. 924–30. https://doi.org/10.2320/materia1962.29.924.

S.-I. Tanaka and Y. Takahashi: ISIJ Int., 1990, vol. 30, pp. 1086–91. https://doi.org/10.2355/isi**ternational.30.1086.

M. Araki and K. Matsuda: Mater. Trans., 2020, vol. 61, pp. 104–10. https://doi.org/10.2320/matertrans.MT-M2019226.

M. Araki, K. Matsuda, S. Lee, T. Tsuchiya, and S. Ikeno: Keikinzoku/J. Jpn. Inst. Light Met., 2019, vol. 69, pp. 327–31. https://doi.org/10.2464/jilm.69.327.

K. Ihara and T. Shikama: Proceedings of the 12th International Conference on Aluminium Alloys, 2012, pp. 2012–17. http://www.icaa-conference.net/ICAA12/pdf/P073.pdf.

H. Takeda, A. Hibino, and K. Takata: Mater. Trans., 2010, vol. 51, pp. 614–19. https://doi.org/10.2320/matertrans.L-MG200951.

S. Ikawa, M. Asano, M. Kuroda, and K. Yoshida: Mater. Sci. Eng. A, 2011, vol. 528, pp. 4050–54. https://doi.org/10.1016/j.msea.2011.01.048.

Acknowledgments

We would like to thank Assistant Professor Funazuka (Toyama University) for facilitating experiments with the 200-ton extrusion device. We would also like to thank Daichi Terada and Yasuaki Tanaka (YKK Corp. Simulation Group, Technology and Innovation Center) for facilitating FEA using the HyperXtrude software.

Funding

This research did not receive any specific grant from funding agencies in the public, commercial, or not-for-profit sectors.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Oda, S., Tanaka, SI. Structure Optimization of Die for 6000-Series Aluminum Alloy Extrusion from Numerical Analysis, Stress Measurement, and Microstructure Observation Perspective. Metall Mater Trans A 53, 4509–4518 (2022). https://doi.org/10.1007/s11661-022-06851-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11661-022-06851-7