Abstract

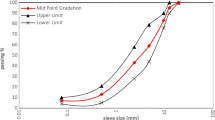

Aiming to analyze the damage mechanism of UTAO from the perspective of meso-mechanical mechanism using discrete element method (DEM), we conducted study of diseases problems of UTAO in several provinces in China, and found that aggregate spalling was one of the main disease types of UTAO. A discrete element model of UTAO pavement structure was constructed to explore the meso-mechanical mechanism of UTAO damage under the influence of layer thickness, gradation, and bonding modulus. The experimental results show that, as the thickness of UTAO decreasing, the maximum value and the mean value of the contact force between all aggregate particles gradually increase, which leads to aggregates more prone to spalling. Compared with OGFC-5 UTAO, AC-5 UTAO presents smaller maximum and average values of all contact forces, and the loading pressure in AC-5 UTAO is fully diffused in the lateral direction. In addition, the increment of pavement modulus strengthens the overall force of aggregate particles inside UTAO, resulting in aggregate particles peeling off more easily. The increase of bonding modulus changes the position where the maximum value of the tangential force appears, whereas has no effect on the normal force.

Similar content being viewed by others

References

Ren JL, Zhang L, Zhao HB, et al. Determination of the Fatigue Equation for the Cement-stabilized Cold Recycled Mixtures with Road Construction Waste Materials Based on Data-driven[J]. International Int. J. Fatigue, 2022, 158: 106765

Gong MY, Zhang HT, Liu ZQ, et al. Study on PQI Standard for ComPrehensive Maintenance of Asphalt Pavement Based on Full-cycle[J]. Int. J. Pavement Eng, 2021: 1–14

Li XL, Ye JH, Badjona Y, et al. Preparation and Performance of Colored Ultra-Thin Overlay for Preventive Maintenance[J]. Constr. Build. Mater., 2020, 249: 118619

Li F, Feng JY, Li YX, et al. Thin Overlay and Ultra-Thin Overlay[M]. Preventive Maintenance Technology for Asphalt Pavement, 2021: 103–127

Zhang HJ, Li H, Zhang Y, et al. Performance Enhancement of Porous Asphalt Pavement Using Red Mud as Alternative Filler[J]. Constr. Build. Mater., 2018, 160: 707–713

Liu ZM, Wang XM, Luo S, et al. Asphalt Mixture Design for Porous Ultra-thin Overlay[J]. Constr. Build. Mater., 2019, 217(2019): 251–264

Ding LT, Wang XC, Zhang KX, et al. Durability Evaluation of Easy Compaction and High-durability Ultra-thin Overlay[J]. Constr. Build. Mater., 2021, 302: 124407

Im S, You T, Kim Y-R, et al. Evaluation of Thin-lift Overlay Pavement Preservation Practice: Mixture Testing, Pavement Performance, and Lifecycle Cost Analysis[J]. Transp. Eng. J., Part B: Pavements, 2018, 144(3): 04018037

Pan YY, Shang Y, Liu GQ, et al. Cost-effectiveness Evaluation of Pavement Maintenance Treatments Using Multiple Regression and Life-cycle Cost Analysis[J]. Constr. Build. Mater., 2021, 292: 123461

Li JS, Zhu Z, Ke L, et al. Rheological Performance Investigation of High Viscosity Liquid Asphalt[J]. Road Mater. Pavement Des., 2020, 22(12): 2 674–2 688

Liu ZM, Luo S, Quan X, et al. Laboratory Evaluation of Performance of Porous Ultra-thin Overlay[J]. Constr. Build. Mater., 2019, 204(2019): 28–40

Yu JM, Chen FD, Deng W, et al. Design and Performance of High-toughness Ultra-thin Friction Course in South China[J]. Constr. Build. Mater., 2020, 246: 118508

Hu MJ, Li LH, Peng FX. Laboratory Investigation of OGFC-5 Porous Asphalt Ultra-thin Wearing Course[J]. Constr. Build. Mater., 2019, 219(2019): 101–110

Zhang JW, Huang WD, Zhang Y, et al. Investigation on the Durability of OGFC-5 Ultra-thin Friction Course with Different Mixes[J]. Constr. Build. Mater., 2021, 288: 123049

Jiang W, Yuan DD, Shan JH, et al. Experimental Study of the Performance of Porous Ultra-thin Asphalt Overlay[J]. Int. J. Pavement Eng., 2020: 1–13

Chen DH, Scullion T. Very Thin Overlays in Texas[J]. Constr. Build. Mater., 2015, 95: 108–116

Labp S, Lamptey G, Konduri S, et al. Analysis of Long-term Effectiveness of Thin Hot-mix Asphaltic Concrete Overlay Treatments[J]. Transport. Res. Rec., 2005, 1940(1): 2–12

Ren JL, Yin C. Investigating Mechanical Characteristics of Aggregate Structure for Road Materials[J]. Int. J. Pavement Eng., 2020, 23(2): 372–386

Xu YS, Jiang YJ, Xue JS, et al. Investigating the Effect of Aggregate Characteristics on the Macroscopic and Microscopic Fracture Mechanisms of Asphalt Concrete at Low-temperature[J]. Mater., 2019, 12(17): 2 675

Yan ZY, Liang JH, Bai YM, et al. Response of Asphalt Pavement Structure Layer and Particle Movement Velocity Based on Particle Flow Theory[J]. J. Constr. Eng. and M., 2021, 147(12): 04021170

Liu GQ, Han DD, Zhao YL, et al. Effects of Asphalt Mixture Structure Types on Force Chains Characteristics Based on Computational Granular Mechanics[J]. Int. J. Pavement Eng., 2020: 1–17

Xu JJ, Li N, Xu T. Temperature Changes of Interlaminar Bonding Layer in Different Seasons and Effects on Mechanical Properties of Asphalt Pavement[J]. Int. J. Pavement Res. Tech., 2022, 15(3): 589–605

Xu J, Kong CW, Xu T. Displacemental and Mesomechanical Responses of Semi-flexible Pavement Based on Discrete Element Method[J]. Int. J. Pavement Res. Tech., 2021: 1–14

Ren JL, Xu YS, Zhao ZD, et al. Fatigue Prediction of Semi-flexible Composite Mixture Based on Damage Evolution[J]. Constr. Build. Mater., 2022, 318: 126004

He DL, Cheng YH. Numerical Simulation for Mechanical Behavior of Asphalt Pavement with Graded Aggregate Base[J]. Adv. Civ. Eng., 2018, 2018: 1–9

Zhu D, Jia XY. Analysis and Simulation of Interlayer Damages in Asphalt Pavement Overlay Cement Concrete Slab[M]. Pavements and Materials: Recent Advances in Design, Testing and Construction, 2011: 192–199

Si CD, Zhou XD, You ZP, et al. Micro-mechanical Analysis of High Modulus Asphalt Concrete Pavement[J]. Constr. Build. Mater., 2019, 220: 128–141

Yan ZY, Chen EH, Wang ZM, et al. Research on Mesoscopic Response of Asphalt Pavement Structure under Vibration Load[J]. Shock and Vibration, 2019, 2019: 1–13

Yan ZY, Wang Z, Chen JX, et al. Micromechanical Response of Asphalt Pavement under Temperature-vehicle Load[J]. Journal of Bei**g Jiaotong University, 2020, 44(3): 118–128

Khavassefat P, Jelagin D, Birgisson B. Dynamic Response of Flexible Pavements at Vehicle-road Interaction[J]. Road Mater. Pavement Des., 2014, 16(2): 256–276

Xu OM, Cao ZF, Li MY, et al. Review of Ultra-thin Overlay Asphalt Concrete Application and Development[J]. China Sciencepaper, 2020, 15(4): 7

Ren JL, Zhao HB, Zhang L, et al. Design Optimization of Cement Grouting Material Based on Adaptive Boosting Algorithm and Simplicial Homology Global Optimization[J]. J. Build. Eng., 2022, 49: 104049

Zhao ZF, Guan X, **ao FP, et al. Applications of Asphalt Concrete Overlay on Portland Cement Concrete Pavement[J]. Constr. Build. Mater., 2020, 264: 120045

Shi K, Zhang YF, Gao YL, et al. Effects of Adhesives on Properties and Mechanism of the Ultra-thin Pavement[J]. Road Mater. Pavement Des., 2021, 22(5): 1 140–1 159

Ministry of Transport of the People’s Republic of China. Technical Standards of the Chinese Technical Specifications for Construction of Highway Asphalt Pavements[S]. JTG F40–2004, China Communications Press, Bei**g, China, 2004

Liu Y, You ZP. Discrete-Element Modeling: Impacts of Aggregate Sphericity, Orientation, and Angularity on Creep Stiffness of Idealized Asphalt Mixtures[J]. J. Eng. Mech., 2011, 137(4): 294–303

Ministry of Transport of the People’s Republic of China. Specifications for Design of Highway Asphalt Pavement[S]. JTG D50–2017, China Communications Press, Bei**g, China, 2017

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

All authors declare that there are no competing interests.

Rights and permissions

About this article

Cite this article

Du, X., Gao, L., Rao, F. et al. Damage Mechanism of Ultra-thin Asphalt Overlay (UTAO) based on Discrete Element Method. J. Wuhan Univ. Technol.-Mat. Sci. Edit. 39, 473–486 (2024). https://doi.org/10.1007/s11595-024-2903-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11595-024-2903-9