Abstract

During tunnel construction with tunnel boring machine (TBM), the TBM drivers determine the driving parameters depending only on their own experiences. Inappropriate TBM driving parameters may lead to low construction efficiency, severe disk cutter wear, even tunnel collapse. An assisted driving method for TBM is proposed in this study to assist drivers in determining suitable driving parameters in advance taking into account both the construction safety and efficiency. The proposed method starts with develo** a model to classify the grade of surrounding rock masses and a deep learning model to predict the TBM tunneling parameters (i.e., torque and thrust). Then, the models are used to predict the integrity and drivability of the surrounding rock in the tunneling. Finally, appropriate driving parameters for TBM in different rock grades and drivability classes can be determined automatically. This assisted driving method was examined by the data from Yin-song project in China. Essentially, this study can be helpful for the evaluation of rock mass drivability and the determination of driving parameters, paving the way to a self-driving machine in the harsh tunnel boring environment.

Similar content being viewed by others

References

Alber M (2000) Advance rates of hard rock TBMs and their effects on project economics. Tunn Undergr Space Technol 15(1):55–64

Bastian A, Sujadi H, Febrianto DG (2018) Penerapan algoritma K-means clustering analysis pada aenyakit menular manusia (Studi Kasus Kabupaten Majalengka). Jurnal Sistem Informasi 14(1):28–34

Breiman L (2001) Random forests. Mach Learn 45(1):5–32

Bruland A (1998) Hard rock tunnel boring. D.E. thesis, Norwegian University of Science and Technology

Chen K, Sun ZC, Li T (2018) TBM design and construction. China Communications Press Co. Ltd, Bei**g

Chen ZY, Zhang YP, Li JB et al (2021) Diagnosing tunnel collapse sections based on TBM tunneling big data and deep learning: a case study on the Yinsong Project, China. Tunnel Undergr Space Technol 108:103700

Hassanpour J, Rostami J, Khamehchiyan M et al (2010) TBM performance analysis in pyroclastic rocks: A case history of Karaj water conveyance tunnel. Rock Mech Rock Eng 43:427–455

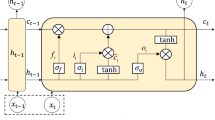

Hochreiter S, Schmidhuber J (1997) Long short-term memory. Neural Comput 9(8):1735–1780

**g LJ, Li JB, Yang C et al (2019) A case study of TBM performance prediction using field tunnelling tests in limestone strata. Tunn Undergr Space Technol 83:364–372

Li JH, Li PX, Guo D et al (2021) Advanced prediction of tunnel boring machine performance based on big data. Geosci Front 12(1):331–338

Liu ZQ, Guo D, Lacasse S et al (2020) Algorithms for intelligent prediction of landslide displacements. J Zhejiang Univ Sci A 21:412–429

Ozdemir L (1977) Development of theoretical equations for predicting tunnel boring ability. D.E. thesis, Colorado School of Mines

Sandri M, Zuccolotto P (2006) Variable selection using random forests. In: Zani S, Cerioli A, Riani M, Vichi M (eds) Data analysis, classification and the forward search. Studies in classification, data analysis, and knowledge organization. Springer, Berlin

Sanio HP (1985) Prediction of the performance of disc cutters in anisotropic rock. Int J Rock Mech Min Sci Geomech Abstr 22(3):153–161

Sapigni M, Berti M, Bethaz E et al (2002) TBM performance estimation using rock mass classifications. Int J Rock Mech Min Sci 39(6):771–788

Yagiz S (2002) Development of rock fracture and brittleness indices to quantify the effects of rock mass features and toughness in the CSM model basic penetration for hard rock tunneling machines. D.E. thesis, Colorado School of Mines

Yagiz S (2008) Utilizing rock mass properties for predicting TBM performance in hard rock condition. Tunn Undergr Space Technol 23(3):326–339

Zhang WG, Zhang RH, Wu CZ et al (2020) State-of-the-art review of soft computing applications in underground excavations. Geosci Front 11(4):1095–1106

Zhu CS, Idemudia CW, Feng WF (2019) Improved logistic regression model for diabetes prediction by integrating PCA and K-means techniques. Inform Med Unlocked 17:100179

Acknowledgements

This work was supported by National Key R&D Program of China (2019YFC1511104), Shenzhen Peacock Technology Innovation Project (KQJSCX20180328165808449) and Shenzhen Key Laboratory Launching Project (ZDSYS20200810113601005). Thanks for the support of China Railway Engineering Equipment Group Corporation for providing the comprehensive database in this study.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Guo, D., Li, J., Jiang, SH. et al. Intelligent assistant driving method for tunnel boring machine based on big data. Acta Geotech. 17, 1019–1030 (2022). https://doi.org/10.1007/s11440-021-01327-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11440-021-01327-1