Abstract

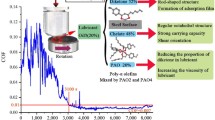

In this article, 1-(4-ethylphenyl)-nonane-1,3-dione (0206) was prepared by Claisen condensation. By mixing 0206, chelate, and base oil in a ratio of 3.2:4.8:2, a diketone lubricant (PAO=14 (20%)) that can achieve superlubricity was prepared and applied to bearing lubrication experiments. The experimental results show that when the bearing was lubricated by base oil, the friction coefficient (COF) and temperature rise decreased with the decrease of the viscosity of PAO. When PAO=14 (20%) was used as the lubricant, the COF of the bearing was the lowest (0.001), and the wear morphology was comparable to that of the bearing lubricated with commercial lubricant. Compared with the base oil with the same viscosity, it is found that the COF and temperature rise of the bearing lubricated by PAO=14 (20%) were lower under any experimental conditions. And when the amount of lubricant added was 10 µL, the COF of the bearing lubricated by PAO=14 (20%) reached a very low value (0.0004). Bearing ball surface analysis identified the formation of diketone adsorption films. Combined with the previous PAO=14 (20%) superlubricity mechanism, it was considered that the occurrence of tribochemical reaction and the bearing effect of chelates were the main reasons for the existence of ultra-low friction coefficient and low wear. In addition, when there were polar molecules in the lubricant, they were adsorbed on the metal surface through tribochemical reactions, resulting in many irregular pits on the surface.

Similar content being viewed by others

References

Dhanola A, Garg H C. Tribological challenges and advancements in wind turbine bearings: A review. Eng Fail Anal, 2020, 118: 104885

Wei Y, Li Y, Xu M, et al. A review of early fault diagnosis approaches and their applications in rotating machinery. Entropy, 2019, 21: 409

Sadabadi H, Sanati Nezhad A. Nanofluids for performance improvement of heavy machinery journal bearings: A simulation study. Nanomaterials, 2020, 10: 2120

Alves D S, Machado T H, Cavalca K L, et al. Characteristics of oil film nonlinearity in bearings and its effects in rotor balancing. J Sound Vib, 2019, 459: 114854

**e Z L, Jiao J, Yang K, et al. Investigation on the stability and anti-eccentric load margin of a novel structure bearing lubricated by low viscosity medium. Sci China Tech Sci, 2022, 65: 1613–1633

Santos N D S A, Roso V R, Faria M T C. Review of engine journal bearing tribology in start-stop applications. Eng Fail Anal, 2020, 108: 104344

Zhang Z, Zhang H, Wang J, et al. Study on mechanics and high temperature tribological properties of porous bearing cage material. J Reinforced Plasts Compos, 2023, 07316844231201479

Kumar N, Satapathy R K. Bearings in aerospace, application, distress, and life: A review. J Fail Anal Preven, 2023, 23: 915–947

Gupta P K, Gibson H G. Real-time dynamics modeling of cryogenic ball bearings with thermal coupling. J Tribol, 2021, 143: 031201

Rejith R, Kesavan D, Chakravarthy P, et al. Bearings for aerospace applications. Tribol Int, 2023, 181: 108312

Nicholas G, Howard T, Long H, et al. Measurement of roller load, load variation, and lubrication in a wind turbine gearbox high speed shaft bearing in the field. Tribol Int, 2020, 148: 106322

Berman D, Erdemir A, Sumant A V. Graphene: A new emerging lubricant. Mater Today, 2014, 17: 31–42

Pimenov D Y, Mia M, Gupta M K, et al. Resource saving by optimization and machining environments for sustainable manufacturing: A review and future prospects. Renew Sustain Energy Rev, 2022, 166: 112660

Said Z, Rahman S M A, Sohail M A, et al. Nano-refrigerants and nano-lubricants in refrigeration: Synthesis, mechanisms, applications, and challenges. Appl Therm Eng, 2023, 233: 121211

Wu C, **e Y, Zhao H, et al. Effects of hBN and CaCO3 nanoparticles on tribological and vibration properties of polyurea grease on rolling bearing. Tribol Lett, 2022, 70: 95

Dokshanin S G, Tynchenko V S, Bukhtoyarov V V, et al. Investigation of the tribological properties of ultrafine diamond-graphite powder as an additive to greases. IOP Conf Ser-Mater Sci Eng, 2019, 560: 012192

Liñeira del Río J M, López E R, Gonçalves D E P, et al. Tribological properties of hexagonal boron nitride nanoparticles or graphene nanoplatelets blended with an ionic liquid as additives of an ester base oil. Lubrication Sci, 2021, 33: 269–278

Hirano M, Shinjo K, Kaneko R. Observation of superlubricity by scanning tunneling microscopy. Phys Rev Lett, 1997, 78: 14481451

Chen X, Li J. Superlubricity of carbon nanostructures. Carbon, 2020, 158: 1–23

Matta C, Joly-Pottuz L, De Barros Bouchet M I, et al. Superlubricity and tribochemistry of polyhydric alcohols. Phys Rev B, 2008, 78: 085436

Li J, Zhang C, Deng M, et al. Superlubricity of silicone oil achieved between two surfaces by running-in with acid solution. RSC Adv, 2015, 5: 30861–30868

Zeng Q, Dong G. Influence of load and sliding speed on super-low friction of Nitinol 60 alloy under castor oil lubrication. Tribol Lett, 2013, 52: 47–55

Ge X, Halmans T, Li J, et al. Molecular behaviors in thin film lubrication—Part three: Superlubricity attained by polar and nonpolar molecules. Friction, 2019, 7: 625–636

Amann T, Kailer A, Beyer-Faiß S, et al. Development of sintered bearings with minimal friction losses and maximum life time using infiltrated liquid crystalline lubricants. Tribol Int, 2016, 98: 282–291

Amann T, Kailer A. Ultralow friction of mesogenic fluid mixtures in tribological reciprocating systems. Tribol Lett, 2010, 37: 343–352

Amann T, Kailer A. Analysis of the ultralow friction behavior of a mesogenic fluid in a reciprocating contact. Wear, 2011, 271: 1701–1706

Li K, Zhang S, Liu D, et al. Superlubricity of 1,3-diketone based on autonomous viscosity control at various velocities. Tribol Int, 2018, 126: 127–132

Du S, Zhang C, Luo Z. The synergistic effect of diketone and its chelate enables macroscale superlubricity for a steel/steel contact. Tribol Int, 2022, 173: 107610

Zhang S, Zhang C, Li K, et al. Investigation of ultra-low friction on steel surfaces with diketone lubricants. RSC Adv, 2018, 8: 9402–9408

Du S, Zhang C, Luo Z. Combination ofdiketone and PAO to achieve macroscale oil-based superlubricity at relative high contact pressures. Friction, 2024, 12: 869–883

Li K, Jiang J, Amann T, et al. Evaluation of 1,3-diketone as a novel friction modifier for lubricating oils. Wear, 2020, 452–453: 203299

Olaru D N, Bălan M R D, Tufescu A, et al. Influence of the cage on the friction torque in low loaded thrust ball bearings operating in lubricated conditions. Tribol Int, 2017, 107: 294–305

Wikstrom V, Hoglund E. Starting and steady-state friction torque of grease-lubricated rolling element bearings at low temperatures-Part H: Correlation with less-complex test methods. Tribol T, 2008, 25: 684–690

Houpert L. Ball bearing and tapered roller bearing torque: Analytical, numerical and experimental results. Tribol Trans, 2002, 45: 345–353

Sia S Y, Sarhan A A D. Morphology investigation of worn bearing surfaces using SiO2 nanolubrication system. Int J Adv Manuf Technol, 2014, 70: 1063–1071

Schöfer J, Rehbein P, Stolz U, et al. Formation of tribochemical films and white layers on self-mated bearing steel surfaces in boundary lubricated sliding contact. Wear, 2001, 248: 7–15

Baskar S, Sriram G, Arumugam S. Tribological analysis of a hydrodynamic journal bearing under the influence of synthetic and biolubricants. Tribol Trans, 2017, 60: 428–436

Ren Z, Li B, Zhou Q. Rolling contact fatigue crack propagation on contact surface and subsurface in mixed mode I+II+III fracture. Wear, 2022, 506–507: 204459

Zhang Y, Zeng X, Wu H, et al. The tribological chemistry of a novel borate ester additive and its interaction with ZDDP using XANES and XPS. Tribol Lett, 2014, 53: 533–542

Author information

Authors and Affiliations

Corresponding author

Additional information

This work was supported by the National Key R&D Program of China (Grant No. 2020YFA0711003), the National Natural Science Foundation of China (Grant No. 51925506), and the National Natural Science Foundation of China Youth Science Foundation (Grant No. 52305178).

Rights and permissions

About this article

Cite this article

Du, S., Zhang, C. & Luo, Z. Study on the tribological properties of metal rolling bearing under lubrication with diketone lubricants. Sci. China Technol. Sci. (2024). https://doi.org/10.1007/s11431-024-2719-y

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s11431-024-2719-y