Abstract

The hybrid manifold micro-pin-fin (MMPF) heat sink combined nozzle jets is an option for large-scale integrated circuits (LSI). The demond for uniform and ultra-high heat flux removal by MMPF heat sink has not been adequately investigated. This work aims to solve the problem of fluid organization. The proposed basic tiling topologies, including square, regular hexagon, 30° rhombus, and 60° rhombus topologies, provide different organized fluid flows and heat transfer patterns. The present study focuses on comparing these topologies according to independent porous medium parameters, such as nozzle pore size DZ, flow pore size DX,Y, and porosity ε. The results show that the square topology achieves the smallest total thermal resistance Rtot value of 0.0975 × 10−4 K m2/W, while the hexagon topology achieved the highest value of COP/ΔT, which was 2033.9 K−1. According to the sensitivity analysis results, the optimal total thermal resistance can be obtained by balancing the influences of nozzle pore size, flow pore size, and porosity. The optimal pressure drop can be obtained by maximizing the porosity.

Similar content being viewed by others

References

Tang H, Tang Y, Zhuang B, et al. Experimental investigation of the thermal performance of heat pipes with double-ended heating and middle-cooling. Energy Convers Manage, 2017, 148: 1332–1345

Chen Y, Li B, Wang X, et al. Investigation of heat transfer and thermal stresses of novel thermal management system integrated with vapour chamber for igbt power module. Thermal Sci Eng Prog, 2019, 10: 73–81

Wen H, Liang Z, Luo Q, et al. Heat transfer performance study of microchannel heat sink with composite secondary channels. Int Commun Heat Mass Transfer, 2023, 143: 106718

Kong L, Liu Z, Jia L, et al. Experimental study on flow and heat transfer characteristics at onset of nucleate boiling in micro pin fin heat sinks. Exp Thermal Fluid Sci, 2020, 115: 109946

Guo Y C, Li Z G, Wang K, et al. A transient multiphysics coupling method based on openfoam for heat pipe cooled reactors. Sci China Tech Sci, 2022, 65: 102–114

Le Q, Shi Q, Liu Q, et al. Numerical investigation on manifold immersion cooling scheme for lithium ion battery thermal management application. Int J Heat Mass Transfer, 2022, 190: 122750

Ju X, Xu C, Liao Z, et al. A review of concentrated photovoltaic-thermal (CPVT) hybrid solar systems with waste heat recovery (WHR). Sci Bull, 2017, 62: 1388–1426

Ju X, Xu C, Han X, et al. A review of the concentrated photovoltaic/thermal (CPVT) hybrid solar systems based on the spectral beam splitting technology. Appl Energy, 2017, 187: 534–563

Colangelo G, Favale E, Milanese M, et al. Cooling of electronic devices: Nanofluids contribution. Appl Thermal Eng, 2017, 127: 421–435

Bandaru S V R, Villanueva W, Konovalenko A, et al. Upward-facing multi-nozzle spray cooling experiments for external cooling of reactor pressure vessels. Int J Heat Mass Transfer, 2020, 163: 120516

Lu Z, Salamon T R, Narayanan S, et al. Design and modeling of membrane-based evaporative cooling devices for thermal management of high heat fluxes. IEEE Trans Compon Packag Manufact Technol, 2016, 6: 1056–1065

Cui X, Yan W, Liu Y, et al. Performance analysis of a hollow fiber membrane-based heat and mass exchanger for evaporative cooling. Appl Energy, 2020, 271: 115238

Muneeshwaran M, Tsai M K, Wang C C. Heat transfer augmentation of natural convection heat sink through notched fin design. Int Commun Heat Mass Transfer, 2023, 142: 106676

Zhou J H, Chen X M, Li Q. Numerical study on two-phase boiling heat transfer performance of interrupted microchannel heat sinks. Sci China Tech Sci, 2022, 65: 679–692

Shao S, Liu H, Zhang H, et al. Experimental investigation on a loop thermosyphon with evaporative condenser for free cooling of data centers. Energy, 2019, 185: 829–836

Tuckerman D B, Pease R F W. High-performance heat sinking for vlsi. IEEE Electron Device Lett, 1981, 2: 126–129

van Erp R, Soleimanzadeh R, Nela L, et al. Co-designing electronics with microfluidics for more sustainable cooling. Nature, 2020, 585: 211–216

Hadipour A, Rajabi Zargarabadi M, Dehghan M. Effect of micro-pin characteristics on flow and heat transfer by a circular jet im**ing to the flat surface. J Therm Anal Calorim, 2020, 140: 943–951

Gil P, Wilk J, Smusz R, et al. Centerline heat transfer coefficient distributions of synthetic jets im**ement cooling. Int J Heat Mass Transfer, 2020, 160: 120147

Tepe A Ü, Uysal Ü, Yetişken Y, et al. Jet im**ement cooling on a rib-roughened surface using extended jet holes. Appl Thermal Eng, 2020, 178: 115601

Tepe A Ü, Yetişken Y, Uysal Ü, et al. Experimental and numerical investigation of jet im**ement cooling using extended jet holes. Int J Heat Mass Transfer, 2020, 158: 119945

Wu R, Fan Y, Hong T, et al. An immersed jet array im**ement cooling device with distributed returns for direct body liquid cooling of high power electronics. Appl Thermal Eng, 2019, 162: 114259

Kim S M, Afzal A, Kim K Y. Optimization of a staggered jet-convex dimple array cooling system. Int J Thermal Sci, 2016, 99: 161–169

Hoberg T B, Onstad A J, Eaton J K. Heat transfer measurements for jet im**ement arrays with local extraction. Int J Heat Fluid Flow, 2010, 31: 460–467

Cui F L, Hong F J, Cheng P. Comparison of normal and distributed jet array im**ement boiling of HFE-7000 on smooth and pin-fin surfaces. Int J Heat Mass Transfer, 2018, 126: 1287–1298

Wang L, **e Z H, Chen L G, et al. Equivalent thermal resistance minimization for a circular disc heat sink with reverting microchannels based on constructal theory and entransy theory. Sci China Tech Sci, 2021, 64: 111–121

Manikanda Kumaran R, Kumaraguruparan G, Sornakumar T. Experimental and numerical studies of header design and inlet/outlet configurations on flow mal-distribution in parallel micro-channels. Appl Thermal Eng, 2013, 58: 205–216

Huang F, Qiu D, Xu Z, et al. Analysis and improvement of flow distribution in manifold for proton exchange membrane fuel cell stacks. Energy, 2021, 226: 120427

He Z, Yan Y, Feng S, et al. Multi-objective optimizations on thermal and hydraulic performance of symmetric and asymmetric bionic y-shaped fractal networks by genetic algorithm coupled with cfd simulation. Int Commun Heat Mass Transfer, 2021, 124: 105261

Chen Y, Cheng P. An experimental investigation on the thermal efficiency of fractal tree-like microchannel nets. Int Commun Heat Mass Transfer, 2005, 32: 931–938

Tan H, Wu L, Wang M, et al. Heat transfer improvement in microchannel heat sink by topology design and optimization for high heat flux chip cooling. Int J Heat Mass Transfer, 2019, 129: 681–689

Ghani I A, Che Sidik N A, Kamaruzzaman N, et al. The effect of manifold zone parameters on hydrothermal performance of microchannel heatsink: A review. Int J Heat Mass Transfer, 2017, 109: 1143–1161

Alihosseini Y, Zabetian Targhi M, Heyhat M M, et al. Effect of a micro heat sink geometric design on thermo-hydraulic performance: A review. Appl Thermal Eng, 2020, 170: 114974

Siddiqui O K, Zubair S M. Efficient energy utilization through proper design of microchannel heat exchanger manifolds: A comprehensive review. Renew Sustain Energy Rev, 2017, 74: 969–1002

He Z, Yan Y, Zhang Z. Thermal management and temperature uniformity enhancement of electronic devices by micro heat sinks: A review. Energy, 2021, 216: 119223

Chen L G, Yang A B, Feng H J, et al. Constructal design progress for eight types of heat sinks. Sci China Tech Sci, 2020, 63: 879–911

Lee J, Kim Y, Lorente S, et al. Constructal design of a comb-like channel network for self-healing and self-cooling. Int J Heat Mass Transfer, 2013, 66: 898–905

Yan Y, Yan H, Yin S, et al. Single/multi-objective optimizations on hydraulic and thermal management in micro-channel heat sink with bionic y-shaped fractal network by genetic algorithm coupled with numerical simulation. Int J Heat Mass Transfer, 2019, 129: 468–479

Bejan A, Lorente S. Design with Constructal Theory. Hoboken: John Wiley & Sons Inc., 2008

Bejan A. Entropy Generation Minimization: The Method of Thermodynamic Optimization of Finite-Size Systems and Finite-Time Processes. Boca Raton: CRC Press, 1995

Tondeur D, Luo L. Design and scaling laws of ramified fluid distributors by the constructal approach. Chem Eng Sci, 2004, 59: 1799–1813

Tondeur D, Fan Y, Commenge J M, et al. Flow and pressure distribution in linear discrete “ladder-type” fluidic circuits: An analytical approach. Chem Eng Sci, 2011, 66: 2568–2586

Guo Z Y, Zhu H Y, Liang X G. Entransy—A physical quantity describing heat transfer ability. Int J Heat Mass Transfer, 2007, 50: 2545–2556

Gilmore N, Timchenko V, Menictas C. Manifold microchannel heat sink topology optimisation. Int J Heat Mass Transfer, 2021, 170: 121025

Wei T, Oprins H, Cherman V, et al. Experimental and numerical investigation of direct liquid jet im**ing cooling using 3D printed manifolds on lidded and lidless packages for 2.5D integrated systems. Appl Thermal Eng, 2020, 164: 114535

He Z, Yan Y, Xu F, et al. Combustion characteristics and thermal enhancement of premixed hydrogen/air in micro combustor with pin fin arrays. Int J Hydrogen Energy, 2020, 45: 5014–5027

Escher W, Michel B, Poulikakos D. A novel high performance, ultra thin heat sink for electronics. Int J Heat Fluid Flow, 2010, 31: 586–598

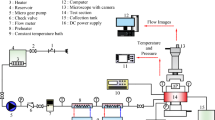

Ju X, Xu C, Zhou Y, et al. Numerical investigation of a novel manifold micro-pin-fin heat sink combining chessboard nozzle-jet concept for ultra-high heat flux removal. Int J Heat Mass Transfer, 2018, 126: 1206–1218

Yao X L, Shi Q L, Liu Q, et al. An investigation on application potentiality of microstructure heat sinks with different flow topological morphology. Sci China Tech Sci, 2022, 65: 2895–2909

Shi Q L, Liu Q, Li K X, et al. Numerical investigation of different nozzle-jet distributions based on chessboard high-topology composite heat sink (in Chinese). Sci Sin Tech, 2021, 51: 699–710

Shi Q, Liu Q, Yao X, et al. Optimal design on irregular polygon topology for the manifold micro-pin-fin heat sink. Int Commun Heat Mass Transfer, 2023, 141: 106574

Huggett S A, Mason L J, Tod K P, et al. The Geometric Universe. London: Oxford University Press, 1998

Kim S J. Methods for thermal optimization of microchannel heat sinks. Heat Transfer Eng, 2004, 25: 37–49

Gong L, Li Y, Bai Z, et al. Thermal performance of micro-channel heat sink with metallic porous/solid compound fin design. Appl Thermal Eng, 2018, 137: 288–295

Arie M A, Shooshtari A H, Dessiatoun S V, et al. Numerical modeling and thermal optimization of a single-phase flow manifold-microchannel plate heat exchanger. Int J Heat Mass Transfer, 2015, 81: 478–489

Qu W, Siu-Ho A. Liquid single-phase flow in an array of micro-pin-fins—Part I: Heat transfer characteristics. J Heat Transfer, 2008, 130: 122402

McNaughton K J, Sinclair C G. Submerged jets in short cylindrical flow vessels. J Fluid Mech, 1966, 25: 367–375

Marzban S, Lahmer T. Conceptual implementation of the variance-based sensitivity analysis for the calculation of the first-order effects. J Statistical Theor Pract, 2016, 10: 589–611

Author information

Authors and Affiliations

Corresponding author

About this article

Cite this article

Shi, Q., Yao, X., Liu, Q. et al. An investigation on topologies of hybrid manifold, im**ing-jet nozzle and micro-pin-fin heat sinks. Sci. China Technol. Sci. 67, 1061–1076 (2024). https://doi.org/10.1007/s11431-023-2428-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11431-023-2428-0