Abstract

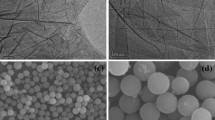

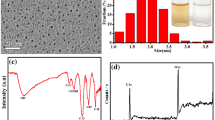

The tribological properties of graphene oxide (GO) nanosheets and modified diamond (MD) nanoparticles with excellent water-solubility were investigated. GO nanosheets were synthesized using carbon fibers with a regular and uniform size, the lateral size being around 30 nm and the thickness being 2 or 3 nm, while MD nanoparticles were about 30 nm in the three dimensions. The friction properties of ceramics were improved by GO nanosheets or MD nanoparticles used as additives in water-based lubrication, though the effects of two nanoparticles were quite different. For GO nanosheets, the friction coefficient at the beginning decreased sharply from 0.6 to 0.1, as compared with the dionized water lubrication. At the same time, the running-in period was shortened from 2000 s to 250 s. A steady state characterized by ultralow friction (friction coefficient=0.01) was obtained after the running-in period. In the case of MD nanoparticles, the friction coefficient stayed at 0.1 without further decrease during the whole experiment. Based on the observation of wear scar and characterization of remains on the wear track, the positive effect of GO nanosheets was attributed to their lamellar structure and geometric size. MD nanoparticles reduced friction by forming the regularly grained surface on the mating surfaces, and prevented further reduction in steady-state friction coefficient owing to their larger size and hardness. In conclusion, GO nanosheets exhibited favorable potential as an effective additive for water-based lubrication.

Similar content being viewed by others

References

Balazs A C, Emrick T. Nanoparticle polymer composites: Where two small worlds meet. Science, 2006, 314(17): 1107–1110

Yu C, Kim Y S, Kim D, et al. Thermoelectric behavior of segregated-network polymer nanocomposites. Nano Lett, 2008, 8(12): 4428–4432

Prasher R, Bhattacharya P, Phelan P. Thermal conductivity of nanoscale colloidal solutions (nanofluids). Phys Rev Lett, 2005, 94: 025901

Li W, Zheng S H, Cao B Q, et al. Friction and wear properties of ZrO2/SiO2 composite nanoparticles. J Nanopart Res, 2010, 13(5): 2129–2137

Bakunin V N, Suslov A Y, Kuzmina G N. Synthesis and application of inorganic nanoparticles as lubricant components — A review. J Nanopart Res, 2004, 6(2-3): 273–284

Lee K, Hwang Y, Cheong S, et al. Understanding the role of nanoparticles in nano-oil lubrication. Tribol Lett, 2009, 35(2): 127–131

Lee K, Hwang Y, Cheong S, et al. Performance evaluation of nano-lubricants of fullerene nanoparticles in refrigeration mineral oil. Current Appl Phys, 2009, 9(2): e128–e131

Yu H L, Xu Y, Shi P J, et al. Tribological behaviors of surface-coated serpentine ultrafine powders as lubricant additive. Tribol Int, 2010, 43(3): 667–675

Qi X W, Jia Z N, Yang Y L, et al. Characterization and auto-restoration mechanism of nanoscale serpentine powder as lubricating oil additive under high temperature. Tribol Int, 2011, 44(7–8): 805–810

Bandyopadhyaya R, Kumar R. Modelling of CaCO3 nanoparticle formation during overbasing of lubricating oil additives. Langmuir, 2001, 17(4): 1015–1029

Ji X B, Chen Y, Zhao G Q, et al. Tribological Properties of CaCO3 nanoparticles as an additive in lithium grease. Tribol Lett, 2010, 41(1): 113–119

Huang H D, Tu J P, Gan L P, et al. An investigation on tribological properties of graphite nanosheets as oil additive. Wear, 2006, 261(2): 140–144

Rosentsveig R, Gorodnev A, Feuerstein N, et al. Fullerene-like MoS2 nanoparticles and their tribological behavior. Tribol Lett, 2009, 36(2): 175–182

Hu K H, Liu M, Wang Q J, et al. Tribological properties of molybdenum disulfide nanosheets by monolayer restacking process as additive in liquid paraffin. Tribol Int, 2009, 42(1): 33–39

Kolodziejczyk L, Martínez-Martínez D, Rojas T C, et al. Surface-modified Pd nanoparticles as a superior additive for lubrication. J Nanopart Res, 2006, 9(4): 639–645

Sánchez-López J C, Abad M D, Kolodziejczyk L, et al. Surface-modified Pd and Au nanoparticles for anti-wear applications. Tribol Int, 2011, 44(6): 720–726

Tarasov S, Kolubaev A, Belyaev S, et al. Study of friction reduction by nanocopper additives to motor oil. Wear, 2002, 252(1–2): 63–69

Kang X, Wang B, Zhu L, et al. Synthesis and tribological property study of oleic acid-modified copper sulfide nanoparticles. Wear, 2008, 265(1–2): 150–154

Sulek M W, Wasilewski T. Antiseizure properties of aqueous solutions of compounds forming liquid crystalline structures. Tribol Lett, 2005, 18(2): 197–205

Sulek M W, Wasilewski T, KurzydŁowski K J. The effect of concentration on lubricating properties of aqueous solutions of sodium lauryl sulfate and ethoxylated sodium lauryl sulfate. Tribol Lett, 2010, 40(3): 337–345

Tomala A, Karpinska A, Werner W S M, et al. Tribological properties of additives for water-based lubricants. Wear, 2010, 269(11–12): 804–810

Zhang C H, Zhao Y C, Björling M, et al. EHL properties of polyalkylene glycols and their aqueous solutions. Tribol Lett, 2011, 45(3): 379–385

Novoselov K S, Geim A K, Morozov S V, et al. Electric field effect in atomically thin carbon film. Science, 2004, 306(5696): 666–669

Lee C, Wei X D, Kysar J W, et al. Measurement of the elastic properties and intrinsic strength of monolayer graphene. Science, 2008, 321(5887): 385–388

Ou J F, Wang J Q, Liu S, et al. Tribology study of reduced graphene oxide sheets on silicon substrate synthesized via covalent assembly. Langmuir, 2010, 26(20): 15830–15836

Pu J B, Wan S H, Zhao W J, et al. Preparation and Tribological study of functionalized graphene-IL nanocomposite ultrathin lubrication films on Si substrates. J Phys Chem C, 2011, 115(27): 13275–13284

Ou J F, Wang Y, Wang J Q, et al. Self-assembly of octadecyltrichlorosilane on graphene oxide and the tribological performances of the resultant film. J Phys Chem C, 2011, 115(20): 10080–10086

Liu S, Ou J F, Li Z P, et al. Layer-by-layer assembly and tribological property of multilayer ultrathin films constructed by modified graphene sheets and polyethyleneimine. Appl Surf Sci, 2012, 258(7): 2231–2236

Luo J Y, Cote L J, Tung V C, et al. Graphene oxide nanocolloids. J Am Chem Soc, 2010, 132(50): 17667–17669

Hummers W S, Offeman R E. Preparation of graphitic oxide. J Amer Chem, 1958, 80(6): 1339–1339

Kim F, Luo J Y, Cruz-Silva R, et al. Self-propagating domino-like reactions in oxidized graphite. Adv Funct Mater, 2010, 20(17): 2867–2873

Tomizawa H, Fischer T E. Friction and wear of silicon nitride and silicon carbide in water: Hydrodynamic lubrication at low sliding speed obtained by tribochemical wear. ASLE Trans, 1987, 30(1): 41–46

Xu J G, Kato K. Formation of tribochemical layer of ceramics sliding in water and its role for low friction. Wear, 2000, 245(1–2): 61–75

Jahanmir S, Ozmen Y, Ives L K. Water lubrication of silicon nitride in sliding. Tribol Lett, 2004, 17(3): 409–417

Gates R S, Hsu S M. Tribochemistry between water and Si3N4 and SiC: Induction time analysis. Tribol Lett, 2004, 17(3): 399–407

Author information

Authors and Affiliations

Corresponding author

Additional information

These two authors contribute equally to this paper

Rights and permissions

About this article

Cite this article

Liu, Y., Wang, X., Pan, G. et al. A comparative study between graphene oxide and diamond nanoparticles as water-based lubricating additives. Sci. China Technol. Sci. 56, 152–157 (2013). https://doi.org/10.1007/s11431-012-5026-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11431-012-5026-z