Abstract

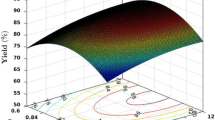

Currently, biodiesel is produced from non-edible oils, which have various poisonous and un-saponifiable components; therefore, it is harmful and unfit for humans. Biodiesel replaces petro-diesel fuel, which can be used as additives or substitutes for diesel engines. The novelty of the present study is to optimize the process parameters of a two-step (esterification and transesterification) process for biodiesel production using high free fatty acid (FFA) containing Karanja oil (Pongamia pinnata oil), with the ultrasound (US) process intensification (PI) technique, which is carried out for the first time. In the first step, a reduction in the initial FFA concentration of 11.06% was achieved through optimization of the esterification process using response surface methodology (RSM)-supported central composite design (CCD) method in which methanol:oil molar ratio of 6:1 and 60 °C reaction temperature kept as fixed parameter, whereas H2SO4 catalyst loading (0.5–1.5 w/w%) and reaction time (15–45 min.) were varied. The FFA value is reduced to 1.56% under the optimal condition (32.8 min reaction time and 1.14 w/w% of catalyst loading). The second step of optimization of the transesterification of esterified oil was performed by applying RSM supported Box-Behnken design (BBD) method with varying independent parameter ranges such as the molar ratio (A), CH3OK catalyst loading (B), and reaction time (C) with the range of 6:1–9:1 (methanol: oil), 0.5–1.5 w/w%, and 10–30 min., respectively. A biodiesel yield of 98.16% was obtained under optimal conditions of a molar ratio of 7.6:1, catalyst loading of 0.98 w/w%, a reaction time of 20.6 min., and a reaction temperature of 60 °C (constant). Superior optimization results were observed than the conventional stirring method. The biodiesel’s estimated characteristics were discovered to be within ASTM criteria and suitable for blending with diesel fuel.

Similar content being viewed by others

Data Availability

All data generated or analyzed during this study are included in this published article.

References

Abdala E, Nur O, Mustafa MA (2020) Efficient biodiesel production from algae oil using Ca-doped ZnO nanocatalyst. Ind Eng Chem Res 59(43):19235–19243. https://doi.org/10.1021/acs.iecr.0c04118

Andreo-Martínez P, Ortiz-Martínez VM, García-Martínez N, delos Ríos AP, Hernández-Fernández FJ, Quesada-Medina J (2020) Production of biodiesel under supercritical conditions: state of the art and bibliometric analysis. Appl Energy 264:114753. https://doi.org/10.1016/j.apenergy.2020.114753

Aziz ARA, Aziz SA (2018) Application of Box Behnken design to optimize the parameters for Kenaf-Epoxy as noise absorber. IOP Conf Ser Mater Sci Eng 454(1):45–62. https://doi.org/10.1088/1757-899X/454/1/012001

Berwal A, Dahiya A (2014) Production of biodiesel from Karanja Oil. J Alt Energy Sour Technol 5(2):43–49. https://www.stmjournals.com. Accessed 17 Nov 2021

Betiku E, Odude VO, Ishola NB, Bamimore A, Osunleke AS, Okeleye AA (2016) Predictive capability evaluation of RSM, ANFIS and ANN: a case of reduction of high free fatty acid of palm kernel oil via esterification process. Energy Convers Manag 124:219–230. https://doi.org/10.1016/j.enconman.2016.07.030

Bharath GK, Kumar S, Rajesh K, Kumar AH, Sharma S, Balachandran PG (2015) Optimization of biodiesel production from Pongamia oil using Taguchi method. Fuel 140(04):90–96. https://doi.org/10.1016/j.fuel.2014.09.103

Bojaraj D, Sai Bharadwaj AVSL, Khadhar Mohamed MSB, Narayanan A (2021). Conversion of Karanja oil to biodiesel using modified heterogeneous base catalyst. Environ Prog Sustain Energy 40(5). https://doi.org/10.1002/ep.13668

Ekeoma MO, Okoye PAC, Ajiwe VIE, Hameed BH (2021) One-Step conversion of high FFA Crude Karanja oil (Pongamia pinnata) to bio-diesel using portland cement as excellent heterogeneous catalyst. J Chem Soc Nigeria 46(1):114–124. https://journals.chemsociety.org.ng/index.php/jcsn/article/view/568. Accessed 17 Nov 2021

Elango RK, Sathiasivan K, Muthukumaran C, Thangavelu V, Rajesh M, Tamilarasan K (2019) Transesterification of castor oil for biodiesel production: process optimization and characterization. Microchem J 145:1162–1168. https://doi.org/10.1016/j.microc.2018.12.039

Gupta H, Thakkar K, Kachhwaha SS, Kodgire P (2021) Biodiesel production from waste cooking oil using sequential process intensification technique (ultrasound and microwave). IOP Conf Ser Mater Sci Eng 1146(1):012005. https://doi.org/10.1088/1757-899x/1146/1/012005

Harreh D, Saleh AA, Reddy ANR, Hamdan S (2018) An experimental investigation of Karanja biodiesel production in Sarawak, Malaysia. J Eng. https://doi.org/10.1155/2018/4174205

Hussain MN, Janajreh I (2018) Acousto-chemical analysis in multi-transducer sonochemical reactors for biodiesel production. Ultrason Sonochemistry 40:184–193. https://doi.org/10.1016/j.ultsonch.2017.07.009

Joshi SM, Gogate PR, Suresh Kumar S (2018) Intensification of esterification of Karanja oil for production of biodiesel using ultrasound assisted approach with optimization using response surface methodology. Chem Eng Process Process Intensif 124:186–198. https://doi.org/10.1016/j.cep.2017.12.010

Karmakar B, Samanta S, Halder G (2020) Delonix regia heterogeneous catalyzed two-step biodiesel production from Pongamia pinnata oil using methanol and 2-propanol. J Clean Prod 255:120313. https://doi.org/10.1016/j.jclepro.2020.120313

Kodgire P, Sharma A, Kachhwaha SS (2022) Biodiesel production with enhanced fuel properties via appropriation of non-edible oil mixture using conjoint ultrasound and microwave reactor: process optimization and kinetic studies. Fuel Process Techn 230(1):107206. https://doi.org/10.1016/j.fuproc.2022.107206

Krishnamurthy KN, Sridhara SN, Ananda Kumar CS (2020) Optimization and kinetic study of biodiesel production from Hydnocarpus wightiana oil and dairy waste scum using snail shell CaO nano catalyst. Renew Energy 146:280–296. https://doi.org/10.1016/j.renene.2019.06.161

Kumar A, Vachan Tirkey J, Kumar Shukla S (2021) Comparative energy and economic analysis of different vegetable oil plants for biodiesel production in India. Renew Energy 169:266–282. https://doi.org/10.1016/j.renene.2020.12.128

Mathew GM, Raina D, Narisetty V, Kumar V, Saran S, Pugazhendi A, Sindhu R, Pandey A, Binod P (2021) Recent advances in biodiesel production: challenges and solutions. Sci Total Environ 794:148751. https://doi.org/10.1016/j.scitotenv.2021.148751

Meher LC, Naik SN, Das LM (2004) Methanolysis of Pongamia pinnata (karanja) oil for production of biodiesel. J Sci Ind Res 63(11):913–918. https://www.semanticscholar.org/paper/a398409dcd9d42d0ad332e2d4e690a8eb06985bc. Accessed 17 Nov 2021

Mohod AV, Subudhi AS, Gogate PR (2017) Intensification of esterification of non edible oil as sustainable feedstock using cavitational reactors. Ultrason Sonochemistry 36:309–318. https://doi.org/10.1016/j.ultsonch.2016.11.040

Muthukumaran C, Sharmila G, Manojkumar N, Gnanaprakasam A, Sivakumar VM (2020) Optimization and kinetic modeling of biodiesel production. Encyc Renew Sustain Mater 52(12):576–589. https://doi.org/10.1016/b978-0-12-803581-8.10578-8

Naveen S, Gopinath KP, Malolan R, Jayaraman RS, Aakriti K, Arun J (2021) A solar reactor for bio-diesel production from Pongamia oil: studies on transesterification process parameters and energy efficiency. Chin J Chem Eng 40:218–224. https://doi.org/10.1016/j.cjche.2020.10.010

Nigam PS, Singh A (2011) Production of liquid biofuels from renewable resources. Prog Energy Combust Sci 37(1):52–68. https://doi.org/10.1016/j.pecs.2010.01.003

Nookaraju BC, Sohail M (2020) Experimental investigation and optimization of process parameters of hybrid wick heat pipe using with RSM historical data design. Mater Today Proc 58(26):31–42. https://doi.org/10.1016/j.matpr.2020.05.634

Outili N, Kerras H, Nekkab C, Merouani R, Meniai AH (2020) Biodiesel production optimization from waste cooking oil using green chemistry metrics. Renew Energy 145:2575–2586. https://doi.org/10.1016/j.renene.2019.07.152

Oza S, Prajapati N, Kodgire P, Kachhwaha SS (2021) An ultrasound-assisted process for the optimization of biodiesel production from waste cottonseed cooking oil using response surface methodology. Water-Energy Nexus 4:187–198. https://doi.org/10.1016/j.wen.2021.11.001

Pascoal CVP, Oliveira ALL, Figueiredo DD, Assunção JCC (2020) Optimization and kinetic study of ultrasonic-mediated in situ transesterification for biodiesel production from the almonds of Syagrus cearensis. Renew Energy 147:1815–1824. https://doi.org/10.1016/j.renene.2019.09.122

Ponnappan VS, Babu MD, Nagappan B, Devarajan Y (2021) Investigation on the effect of ultrasound irradiation on biodiesel properties and transesterification parameters. Environ Sci Pollut Res 28(45):64769–64777. https://doi.org/10.1007/s11356-021-15568-w

Ranjan A, Singh S, Malani RS, Moholkar VS (2016) Ultrasound-assisted bioalcohol synthesis: review and analysis. RSC Adv 6(70):65541–65562. https://doi.org/10.1039/c6ra11580b

Sharma UC, Sachan S (2019) Experimental investigation on thermal stability of karanja biolubricant base oil. Biofuels Biolubricant 7(13):203–211. https://www.researchgate.net/publication/331895308. Accessed 17 Nov 2021

Sharma A, Kodgire P, Kachhwaha SS (2019) Biodiesel production from waste cotton-seed cooking oil using microwave-assisted transesterification: optimization and kinetic modeling. Renew Sust Energy Rev 116:109394. https://doi.org/10.1016/j.rser.2019.109394

Sharma A, Kodgire P, Kachhwaha SS (2020) Investigation of ultrasound-assisted KOH and CaO catalyzed transesterification for biodiesel production from waste cotton-seed cooking oil: Process optimization and conversion rate evaluation. J Clean Prod 259:120982. https://doi.org/10.1016/j.jclepro.2020.120982

Sharma A, Kodgire P, Kachhwaha SS (2021) An experimental investigation of the performance of biodiesel production techniques: optimization, kinetics, and energy analysis. Therm Sci Eng Prog 22:100842. https://doi.org/10.1016/j.tsep.2021.100842

Shokravi Z, Shokravi H, Aziz MA, Shokravi H (2019) The fourth-generation biofuel: a systematic review on nearly two decades of research from 2008 to 2019. Fossil Free Fuels. https://doi.org/10.1201/9780429327773-12

Singh D, Sharma D, Soni SL, Sharma S, Kumar Sharma P, Jhalani A (2020) A review on feedstocks, production processes, and yield for different generations of biodiesel. Fuel 262:116553. https://doi.org/10.1016/j.fuel.2019.116553

Sundaramahalingam MA, Karthikumar S, Shyam Kumar R, Samuel KJ, Shajahan S, Sivasubramanian V, Sivashanmugam P, Varalakshmi P, Syed A, Marraiki N, Elgorban AM, Vinoth Kumar R, Ganesh Moorthy I (2021) An intensified approach for transesterification of biodiesel from Annona squamosa seed oil using ultrasound-assisted homogeneous catalysis reaction and its process optimization. Fuel 291:120195. https://doi.org/10.1016/j.fuel.2021.120195

Tan YH, Abdullah MO, Nolasco-Hipolito C, Ahmad Zauzi NS (2017) Application of RSM and Taguchi methods for optimizing the transesterification of waste cooking oil catalyzed by solid ostrich and chicken-eggshell derived CaO. Renew Energy 114:437–447. https://doi.org/10.1016/j.renene.2017.07.024

Thakkar K, Shah K, Kodgire P, Kachhwaha SS (2019) In-situ reactive extraction of castor seeds for biodiesel production using the coordinated ultrasound– microwave irradiation: Process optimization and kinetic modeling. Ultrason Sonochemistry 50:6–14. https://doi.org/10.1016/j.ultsonch.2018.08.007

Thakkar K, Kachhawaha SS, Kodgire P, Keshav M (2021) Effectiveness of RSM based Central Composite Design for optimization of in-situ biodiesel production process from castor seeds. IOP Conf Ser Mater Sci Eng 1146(1):012008. https://doi.org/10.1088/1757-899x/1146/1/012008

Thakkar K, Kachhwaha SS, Kodgire P (2022) A novel approach for improved in-situ biodiesel production process from gamma-irradiated castor seeds using synergistic ultrasound and microwave irradiation: Process optimization and kinetic study. Ind Crops Prod 181:114750. https://doi.org/10.1016/j.indcrop.2022.114750

Thakur S, Kaurav H, Chaudhary G (2021) Karanja (Pongamia Pinnata)—an ayurvedic and modern overview. Asian J Pharm Clin Res 14(6):86–92. https://doi.org/10.22159/ajpcr.2021v14i6.41367

Thiruvengadaravi KV, Nandagopal J, Baskaralingam P, Sathya Selva Bala V, Sivanesan S (2012) Acid-catalyzed esterification of karanja (Pongamia pinnata) oil with high free fatty acids for biodiesel production. Fuel 98:1–4. https://doi.org/10.1016/j.fuel.2012.02.047

Zeng D, Yang L, Fang T (2017) Process optimization, kinetic and thermodynamic studies on biodiesel production by supercritical methanol transesterification with CH3ONa catalyst. Fuel 203:739–748. https://doi.org/10.1016/j.fuel.2017.05.019

Zore UK, Yedire SG, Pandi N, Manickam S, Sonawane SH (2021) A review on recent advances in hydrogen energy, fuel cell, biofuel and fuel refining via ultrasound process intensification. Ultrason Sonochemistry 73:105536. https://doi.org/10.1016/j.ultsonch.2021.105536

Acknowledgements

The Centre for Biofuels and Bioenergy Studies (CBBS) in PDEU provided laboratory facilities for this project.

Funding

The authors received funding from the Gujarat Energy Development Agency (GEDA), Gujarat, India.

Author information

Authors and Affiliations

Contributions

All authors contributed to the study’s conception and design. Material preparation, data collection, software development, validation, investigation, original draft writing, and analysis were performed by Suvik Oza and Harshil Thakar. Pravin Kodgire and Surendra Singh Kachhwaha were responsible for conceptualization, providing resources, reviewing and editing the manuscript, creating visualizations, supervising the project, and acquiring funding.

Corresponding author

Ethics declarations

Ethics approval and consent to participate

Not applicable.

Consent for publication

Not applicable.

Competing interests

The authors declare no competing interests.

Additional information

Responsible Editor: Ta Yeong Wu

Publisher's note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Oza, S., Thakar, H., Kodgire, P. et al. Utilizing an ultra-sonication process to optimize a two-step biodiesel production from Karanja oil. Environ Sci Pollut Res (2023). https://doi.org/10.1007/s11356-023-28711-6

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s11356-023-28711-6