Abstract

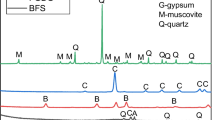

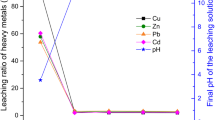

Phosphogypsum (PG) is an industrial waste residue produced during the production of phosphoric acid through the wet process. With strong acidity and a large amount of toxic impurities, PG is difficult to reuse. In this study, the solidified body (PG-S) was made by mechanical compression of the mixture of PG, copper smelting slag (CSS), CaO, NaOH, and water. Results indicate that the composition of the material phases in the PG-S samples changed with hydrated calcium silicate and amorphous silicate derivatives were formed during the reaction; Fe and Ca in the material were transformed; and the prepared geopolymer material had a dense internal structure with the materials being cemented to each other. The highest compressive strength of PG-S cured for 28 days could reach 21.3 MPa with a fixation efficiency of PO43-and F-reaching 99.81 and 94.10%, respectively. The leaching concentration of heavy metals of the PG-S cured for 28 days met the requirements of the Comprehensive Wastewater Discharge Standard (GB 8978-1996). The simulation results of the geochemical model verified the feasibility of the whole immobilization process from the thermodynamic point of view. This work directly uses copper smelting slag and phosphogypsum for coupled immobilization/stabilization treatment not only to achieve the immobilization of pollutants in both solid wastes but also to obtain colloidal masses with certain compressive strength, which also provides a new option for resource utilization of phosphogypsum and copper smelting slag. This work also shows great potential in turning the actual mine backfill into cementitious material.

Graphical Abstract

Similar content being viewed by others

Data availability

All data generated or analyzed during this study are included in this published article.

References

Akihiko Y, Takashi Y (1996): Study of utilization of copper slag as fine aggregate for concrete.

Al-Jabri KS, Hisada M, Al-Oraimi SK, Al-Saidy AH (2009) Copper slag as sand replacement for high performance concrete. Cement Concrete Composites 31:483–488

Ambily PS, Umarani C, Ravisankar K, Prem PR, Bharatkumar BH, Iyer NR (2015) Studies on ultra high performance concrete incorporating copper slag as fine aggregate. Construction Build Mater 77:233–240

Aminul Haque M, Chen B, Liu Y, Farasat Ali Shah S, Ahmad MR (2020) Improvement of physico-mechanical and microstructural properties of magnesium phosphate cement composites comprising with phosphogypsum. J Clean Prod 261:121268

Azouazi M, Ouahidi Y, Fakhi S, Andres Y, Abbe JC, Benmansour M (2001) Natural radioactivity in phosphates, phosphogypsum and natural waters in Morocco. J Environ Radioact 54:231–242

Ben Haha M, Le Saout G, Winnefeld F, Lothenbach B (2011) Influence of activator type on hydration kinetics, hydrate assemblage and microstructural development of alkali activated blast-furnace slags. Cement Concrete Res 41:301–310

Cánovas CR, Macías F, Pérez-López R, Basallote MD, Millán-Becerro R (2018) Valorization of wastes from the fertilizer industry: current status and future trends. J Clean Prod 174:678–690

Chen Q, Zhang Q, Qi C, Fourie A, **ao C (2018) Recycling phosphogypsum and construction demolition waste for cemented paste backfill and its environmental impact. J Clean Prod 186:418–429

Criado M, Fernández-Jiménez A, de la Torre AG, Aranda MAG, Palomo A (2007) An XRD study of the effect of the SiO2/Na2O ratio on the alkali activation of fly ash. Cement Concrete Res 37:671–679

GB/T5085.3-2007 (2007) Identification standards for hazardous wastes—identification for extraction toxicity

Gordon RB (2002) Production residues in copper technological cycles. Resour Conserv Recycling 36:87–106

Gracioli B, Angulski da Luz C, Beutler CS, Pereira Filho JI, Frare A, Rocha JC, Cheriaf M, Hooton RD (2020) Influence of the calcination temperature of phosphogypsum on the performance of supersulfated cements. Construction Build Mater 262:119961

Hagiri M, Honda K (2021) Preparation and evaluation of gypsum plaster composited with copper smelter slag. Clean Eng Technol 2:100084

HJ/T 299-2007. Solid waste - extraction procedure for leaching toxicity

Jalali J, Gaudin P, Capiaux H, Ammar E, Lebeau T (2019) Fate and transport of metal trace elements from phosphogypsum piles in Tunisia and their impact on soil bacteria and wild plants. Ecotoxicol Environ Saf 174:12–25

Kim MS, Jun Y, Lee C, Oh JE (2013) Use of CaO as an activator for producing a price-competitive non-cement structural binder using ground granulated blast furnace slag. Cement Concrete Res 54:208–214

Ku J, Zhang L, Fu W, Wang S, Yin W, Chen H (2021) Mechanistic study on calcium ion diffusion into fayalite: a step toward sustainable management of copper slag. J Hazard Mater 410:124630

Li X, Du J, Gao L, He S, Gan L, Sun C, Shi Y (2017) Immobilization of phosphogypsum for cemented paste backfill and its environmental effect. J Clean Prod 156:137–146

Li J, Sun P, Li J, Lv Y, Ye H, Shao L, Du D (2020) Synthesis of electrolytic manganese residue-fly ash based geopolymers with high compressive strength. Construction Build Mater 248:118489

Liu J, Dong F, Tan H, Zhang H, Zhou L, He P, Zhou L, Feng C, Li R (2020) Facile preparation of high-strength α-CaSO4·0.5H2O regulated by maleic acid from phosphogypsum: experimental and molecular dynamics simulation studies. SN. Appl Sci 2:1645

Lütke SF, Oliveira MLS, Silva LFO, Cadaval TRS, Dotto GL (2020) Nanominerals assemblages and hazardous elements assessment in phosphogypsum from an abandoned phosphate fertilizer industry. Chemosphere 256:127138

Mandal PK, Mandal TK (2002) Anion water in gypsum (CaSO4·2H2O) and hemihydrate (CaSO4·1/2H2O). Cement Concrete Res 32:313–316

Meng X, Li Y, Wang H, Yang Y, McLean A (2020) Effects of Na2O additions to copper slag on iron recovery and the generation of ceramics from the non-magnetic residue. J Hazard Mater 399:122845

Meskini S, Samdi A, Ejjaouani H, Remmal T (2021) Valorization of phosphogypsum as a road material: stabilizing effect of fly ash and lime additives on strength and durability. J Clean Prod 323:129161

Nazer A, Payá J, Borrachero MV, Monzó J (2016) Use of ancient copper slags in Portland cement and alkali activated cement matrices. J Environ Manage 167:115–123

Papaslioti E-M, Pérez-López R, Parviainen A, Sarmiento AM, Nieto JM, Marchesi C, Delgado-Huertas A, Garrido CJ (2018) Effects of seawater mixing on the mobility of trace elements in acid phosphogypsum leachates. Mar Pollut Bull 127:695–703

Piatak NM, Parsons MB, Seal RR (2015) Characteristics and environmental aspects of slag: a review. Appl Geochem 57:236–266

Rutherford PM, Dudas MJ, Samek RA (1994) Environmental impacts of phosphogypsum. Sci Total Environ 149:1–38

Shen W, Zhou M, Zhao Q (2007) Study on lime–fly ash–phosphogypsum binder. Construction Build Mater 21:1480–1485

Shen W, Zhou M, Ma W, Hu J, Cai Z (2009) Investigation on the application of steel slag–fly ash–phosphogypsum solidified material as road base material. J Hazard Mater 164:99–104

Shen Y, Qian J, Chai J, Fan Y (2014) Calcium sulphoaluminate cements made with phosphogypsum: production issues and material properties. Cement Concrete Composites 48:67–74

Singh J, Singh SP (2019) Development of alkali-activated cementitious material using copper slag. Construction Build Mater 211:73–79

Tayibi H, Choura M, López FA, Alguacil FJ, López-Delgado A (2009) Environmental impact and management of phosphogypsum. J Environ Manage 90:2377–2386

Tian T, Yan Y, Hu Z, Xu Y, Chen Y, Shi J (2016) Utilization of original phosphogypsum for the preparation of foam concrete. Construction Build Mater 115:143–152

Tian H, Guo Z, Pan J, Zhu D, Yang C, Xue Y, Li S, Wang D (2021) Comprehensive review on metallurgical recycling and cleaning of copper slag. Resour Conserv Recycling 168:105366

Wang L, Yu K, Li J-S, Tsang DCW, Poon CS, Yoo J-C, Baek K, Ding S, Hou D, Dai J-G (2018) Low-carbon and low-alkalinity stabilization/solidification of high-Pb contaminated soil. Chem Eng J 351:418–427

Wang XqX W (2021) Efficient synergistic stabilization /solidification of phosphogypsum and copper smelter slag. Bull Chin Ceramic Soc 40(05):1601–1609

Zhang S, Zhu N, Mao F, Zhang J, Huang X, Li F, Li X, Wu P, Dang Z (2021) A novel strategy for harmlessness and reduction of copper smelting slags by alkali disaggregation of fayalite (Fe2SiO4) coupling with acid leaching. J Hazard Mater 402:123791

Zhou J, Li X, Zhao Y, Shu Z, Wang Y, Zhang Y, Shen X (2020) Preparation of paper-free and fiber-free plasterboard with high strength using phosphogypsum. Construction Build Mater 243:118091

Zou Q, Da L, Jiang J, Aihemaiti A, Gao Y, Liu N, Liu J (2019) Geochemical simulation of the stabilization process of vanadium-contaminated soil remediated with calcium oxide and ferrous sulfate. Ecotoxicol Environ Saf 174:498–505

Acknowledgements

The study was supported by the Major Innovation Projects of Hubei Province of China (2019ACA156) and Dajiang Co,LTD (HZY21040, China).

Funding

The study was funded by the Major Innovation Projects of Hubei Province (2019ACA156) and the Dajiang Co, LTD (HZY21040, China).

Author information

Authors and Affiliations

Contributions

All authors contributed to the study’s conception and design. Material preparation, data collection, and analysis were performed by **angqun Xu. The first draft of the manuscript was written by **angqun Xu, and all authors commented on previous versions of the manuscript. All authors read and approved the final manuscript.

Corresponding author

Ethics declarations

Ethics approval

Not applicable.

Consent to participate

Not applicable.

Consent for publication

Not applicable.

Competing interests

The authors declare no competing interests.

Additional information

Responsible Editor: Guilherme L. Dotto

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Xu, X., Wang, W., Lv, C. et al. Preparation of phosphogypsum-copper smelting slag-based consolidating body with high compressive strength. Environ Sci Pollut Res 30, 42075–42086 (2023). https://doi.org/10.1007/s11356-023-25241-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11356-023-25241-z