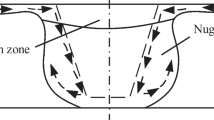

Different morphology and thinning cases of the weld zone of a 7022 aluminum alloy in friction stir welding were analyzed. Metal plastic flow processes in the contact zone for an aerospace friction stir-joint 7022 aluminum alloy were evaluated. The cross section of the contact zon was analyzed by metallographic and tool microscopes. Then, the plastic flow law of the contact zone was established. Theoretical analysis confirmed the validity of the metal plastic flow law and corresponding thinning model of the weld zone. The thinning model for filling due to indirect extrusion–vortex flow can adequately characterize the plastic flow of metals and formation process of thinning in the weld zone.

Similar content being viewed by others

References

G. K. Padhy, C. S. Wu and S. Gao, “Friction stir based welding and processing technologies – processes, parameters, microstructures and applications: A review,” J. Mater. Sci. Tech., 34, No. 4, 1–38 (2018).

M. A. Wahab, M. W. Dewan, D. J. Huggett, et al., “Challenges in the detection of weld-defects in friction-stir-welding (FSW),” Adv. Mater. Process. Technol., 5, No. 2, 258–278 (2019).

M. Guerra, C. Schmidt, J. C. McClure, et al., “Flow patterns during friction stir welding,” Mater. Charact., 49, No. 2, 95–101 (2002).

X. H. Zeng, P. Xue, D. Wang, et al., “Material flow and void defect formation in friction stir welding of aluminium alloys,” Sci. Technol. Weld. Joi., 23, No. 8, 677–686 (2018).

R. Kumar, V. Pancholi, and R. P. Bharti, “Material flow visualization and determination of strain rate during friction stir welding,” J. Mater. Process. Technol., 255, 470–476 (2018).

A. Tongne, C. Desrayaud, M. Jahazi, and E. Feulvarch, “On material flow in Friction Stir Welded Al alloys,” J. Mater. Process. Technol., 239, 284–296 (2017).

L. Shi, C. S. Wu, and H. J. Liu, “Modeling the material flow and heat transfer in reverse dual-rotation friction stir welding,” J. Mater. Eng. Perform., 23, No. 8, 2918–2929 (2014).

S. B. Aziz, M. W. Dewan, D. J. Huggett, et al., “A fully coupled thermomechanical model of friction stir welding (FSW) and numerical studies on process parameters of lightweight aluminum alloy joints,” Acta Metall. Sin.-Engl., 31, No. 1, 1–18 (2018).

A. C. Nunes, Jr., E. L. Bernstrein, and J. C. McClure, “A rotation plug model for friction stir welding,” in: Proc. of the 81st American Welding Society Annual Convention (Chicago: American Welding Society, 2000).

J. A. Schneider and A. C. Nunes, “Characterization of plastic flow and resulting micro- textures in a friction stir weld,” Metall. Mater. Trans. B, 35, No. 4, 777–783 (2004).

J. H. Ouyang and R. Kovacevic, “Material flow and microstructure in the friction stir butt welds of the same and dissimilar aluminum alloys,” J. Mater. Eng. Perform., 11, No. 1, 51–63 (2002).

W. Y. Li, J. F. Li, Z. H. Zhang, et al., “Metal flow during friction stir welding of 7075-T651 aluminum alloy,” Exp. Mech., 53, No. 9, 1573–1582 (2013).

X. J. Wang, C. B. Da, J. Li, and Z. K. Zhong, “Investigation of the technology of friction-stir welding for dissimilar materials of T2 copper to H62 brass,” J. Lanzhou Univ. Technol., 33, No. 1, 29–33 (2007).

K. N. Krishnan, “On the formation of onion rings in friction stir welds,” Mater. Sci. Eng. A, 327, No. 2, 246–251 (2002).

L. M. Ke, L. **ng, and J. E. Indacochea, “Material flow patterns and cavity model in friction-stir welding of aluminum alloys,” Metall. Mater. Trans. B, 35, No. 1, 153–160 (2004).

L. M. Ke, H. L. Pan, and X. Li, “Sucking-extruding theory for the material flow in friction stir welds,” J. Mech. Eng., 45, No. 4, 89–94 (2009).

M. Wang, H. J. Zhang, X. Zhang, et al., “A novel zero-weld-thinning friction sir welding process,” Trans. China Weld. Inst., 37, No. 10, 37–40 (2016).

L. Zhou, R. X. Zhang, X. Y. Hu, et al., “Effects of rotation speed of assisted shoulder on microstructure and mechanical properties of 6061-T6 aluminum alloy by dual-rotation friction stir welding,” Int. J. Adv. Manuf. Technol., 100, Nos. 1–4, 199–208 (2019).

T. Yang, K. S. Wang, W. Wang, et al., “Effect of friction stir processing on microstructure and mechanical properties of AlSi10Mg aluminum alloy produced by selective laser melting,” JOM, 71, No. 5, 1737–1747 (2019).

P. Alvarez, G. Janeiro, and A. A. M. D. Silva, “Material flow and mixing patterns during dissimilar FSW,” Sci. Technol. Weld. Joi., 15, No. 8, 648–653 (2010).

P. Wei, L. **ng, and W. P. Xu, “Influence of plunge depth of shoulder on interface migration of friction stir lap welds,” J. Mater. Eng., 6, 43–47 (2011).

J. R. Xue, Quality Analysis of 2014 Aluminum Alloy Sheet by Friction Stir Welding with High Speed, Jiangsu University of Science and Technology, Zhengjiang (2014).

G. Q. Chen and Q. Y. Shi, “Recent advances in numerical simulation of material flow behavior during frictions stir welding,” J. Mech. Eng., 51, No. 22, 11–20 (2015).

Y. Q. Mao, L. M. Ke, and Z. M. Jiang, “Flow behaviour of plastic metal in extruded zone around tool pin-tip,” Mater. Rep., 32, No. 10, 3612–3617 (2018).

Acknowledgments

This project was supported by the Zhejiang Basic Public Welfare Research Program (Grant No. LGG19E050011), the Public Welfare Projects of Science and Technology Department of Zhejiang Province (Grant No. LGG20E050005), and the Science and Technology Plan Project of Taizhou (Grant No. 1901gy23).

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated from Problemy Prochnosti, No. 4, pp. 70 – 79, July – August, 2020.

Rights and permissions

About this article

Cite this article

Xu, Z.Y., Lin, H.B. Analysis of the Thinning Mechanism of an Aluminum Alloy in Friction Stir Welding Based on the Indirect Extrusion–Vortex Flow Filling Model. Strength Mater 52, 556–564 (2020). https://doi.org/10.1007/s11223-020-00207-5

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11223-020-00207-5