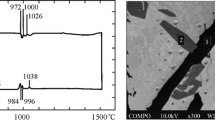

The structurization and phase composition of the alloys produced by in situ thermal synthesis at 1200°C from TiH2–Fe–Ni–B4C powder mixtures were studied. To assess how the mixture composition influenced the structure and properties of the synthesized alloys, five different mixture compositions were prepared. The iron and nickel contents were varied and the content of thermally reacting components (titanium hydride and boron carbide) remained unchanged in all mixtures and was 64 and 16%. Microstructural and X-ray diffraction analyses were conducted for the sintered samples, and the microhardness and particle size distribution were determined for each composition. The resultant composite alloys had a substantially heterophase structure as a basic skeleton consisting of titanium carbide and diboride compounds and a cementing layer consisting of intermetallics and iron and nickel solid solutions. The main alloy phase was titanium carbide, TiCx, whose stoichiometry x varied from 0.43 to 0.54. The introduction of 5% Ni into the mixture somewhat increased the stoichiometry of titanium carbide, but 10% and higher nickel content decreased the stoichiometry. The alloys produced from nickel-containing mixtures had a finer microstructure than the nickel-free alloy did, and all composites in the Fe–Ti–Ni–B4C system were characterized by a significantly finer structure than the boron-free Fe–Ti–Ni–C alloys. The introduction of nickel to the composition also somewhat increased the average microhardness of the synthesized composite.

Similar content being viewed by others

References

Yu.G. Gurevich, V.K. Narva, and N.R. Frage, Carbide Steels [in Russian], Metallurigya, Moscow (1988), p. 144.

J. Kubarsepp, Steel-Bonded Hardmetals [in Russian], Valgus, Tallin Technical University, Tallin (1991).

S.N. Kulkov and S.F. Gnyusov, Carbide Steels Based on Titanium and Tungsten Carbides [in Russian], Izd. NTL, Tomsk (2006), p. 240.

K.I. Parashivamurthy, R.K. Kumar, S. Seetharamu, and M.N. Chandrasekharaiah, “Review on TiC reinforced steel composites,” J. Mater. Sci., 36, 4519–4530 (2001).

Z. Wang, T. Lin, X. He, H. Shao, J. Zheng, and X. Qu, “Microstructure and properties of TiC-high manganese steel cermet prepared by different sintering processes,” J. Alloys Compd., 650, 918–924 (2015).

M. Razavi, M.S. Yaghmaee, M.R. Rahimipour, and S.S. Razavi-Tousi, “The effect of production method on properties of Fe–TiC composite,” Int. J. Miner. Process., 94, 97–100 (2010).

W.C. Zapata, C.E. Da Costa, and J.M. Torralba, “Wear and thermal behavior of M2 high-speed steel reinforced with NbC composite,” J. Mater. Sci., 33, 3219–3225 (1998).

Mi.V. Deshpande, Ma.V. Deshpande, J.P. Saxena, S. Basu, and W. Sebardt, “Toughness cermeted carbide material with iron-rich binder for steel turning,” Int. J. Refract. Met. Hard Mater., 15, No. 1–3, 157–162 (1997).

M. Oliveira and D. Bolton, “Effect of ceramic particles on the mechanical properties of M3/2 high speed steel,” Int. J. Powder Metall., 32, No. 1, 37–49 (1996).

Ye. Kyryliuk, G. Bagliuk, A. Mamonova, and V. Maslyuk, “Synthesis of Fe-based alloy reinforced with chromium carbide via sintering of iron-ferrochrome powder mixture,” Powder Metall. Prog., 21, No. 1, 18–26 (2021).

A. Anal, T.K. Bandyopadhyay, and K. Das, “Synthesis and characterization of TiB2-reinforced iron-based composites,” J. Mater. Proc. Technol., 172, 70–76 (2006).

B. Li, Y. Liu, J. Li, H. Cao, and L. He, “Effect of sintering process on the microstructures and properties of in situ TiB2–TiC reinforced steel matrix composites produced by spark plasma sintering,” J. Mater. Proc. Technol., 210, No. 1, 91–95 (2010).

Z. Zhang, P. Shen, Y. Wang, and Q.-Ch. Jiang, “Fabrication of TiC and TiB2 locally reinforced steel matrix composites using a Fe–Ti–B4C–C system by an SHS-casting route,” J. Mater. Sci., 42(19), 8350–8356 (2007).

A. Biedunkiewicz, W. Biedunkiewicz, P. Figiel, U. Gabriel-Polrolniczak, D. Grzesiak, and M. Krawczyk, “Effect of milling time on thermal treatment of TiC, TiB2/steel powders,” J. Therm. Anal. Calorim., 113, 379–383 (2013).

C.C. Degnan and P.H. Shipway, “A comparison of the reciprocating sliding wear behavior of steel based metal matrix composites processed from self-propagating high-temperature synthesised Fe–TiC and Fe–TiB2 masteralloys,” Wear, 252, 832–841 (2002).

B.S. Terry and O.S. Chinyamakobvu, “Dispersion and reaction of TiB2 in liquid iron alloy,” Mater. Sci. Technol., 8, 491–499 (1992).

C.C. Degnan and P.H. Shipway, “The incorporation of self-propagating, high-temperature synthesis-formed Fe–TiB2 into ferrous melt,” Metall. Mater. Trans. A, 33, 2973–2983 (2002).

Z. Zhang, P. Shen, and Q. Jiang, “Differential thermal analysis (DTA) on the reaction mechanism in Fe–Ti–B4C system,” J. Alloys Compd., 463, 498–502 (2008).

B.H. Li, Y. Liu, J. Li, H. Cao, and L. He, “Fabrication of in situ TiB2–TiC reinforced steel matrix composites by spark plasma sintering,” Powder Metall., 54, No. 3, 222–224 (2011).

G.A. Bagliuk, G.A. Maksimova, A.A. Mamonova, and D.A. Goncharuk, “The structure and phase composition acquired by Fe–Ti–Ni–C alloys in thermal synthesis,” Powder Metall. Met. Ceram., 59, No. 3–4, 171–178 (2020).

O. Іvasishin, G. Bagliuk, O. Stasiuk, and D. Savvakin, “The peculiarities of structure formation upon sintering of TiH2 + TiB2 powder blends,” Phys. Chem. Solid State, 18(1), 15–20 (2017).

G.A. Bagliuk, O.V. Suprun, and A.A. Mamonova, “The influence of the synthesis temperature on phase composition and structure of ternary compounds obtained from the powder mixture of the TiH2–Al–C system,” Phys. Chem. Solid State, 18(4), 438–443 (2017).

G.A. Bagliuk, O.M. Ivasyshyn, O.O. Stasyuk, and D.G. Savvakin, “The effect of charge component composition on the structure and properties of titanium matrix sintered composites with high-modulus compounds,” Powder Metall. Met. Ceram., 56, No. 1–2, 45–52 (2017).

G.V. Samsonov, A.D. Panasyuk, G.K. Kozina, and L.V. Dyakonova, “Contact reaction of refractory compounds with liquid metals,” Powder Metall. Met. Ceram., 11, No. 7, 568–571 (1972).

D.A. Goncharuk and G.A. Baglyuk, “Reaction thermal synthesis of composite sponge from pelletized Fe–Ti–B–C powder mixtures,” Visn. Nats. Tekh. Univ. Ukr. Kyiv Politekh. Inst. Ser. Mashinostr., No. 61, 155–159 (2011).

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated from Poroshkova Metallurgiya, Nos. 3–4 (544), pp. 47–59, 2022.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Bagliuk, G., Maximova, G., Goncharuk, D. et al. The Structurization and Phase Formation of Fe–Ti–Ni–B4C Alloys in Thermal Synthesis. Powder Metall Met Ceram 61, 169–179 (2022). https://doi.org/10.1007/s11106-022-00304-x

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11106-022-00304-x