Abstract

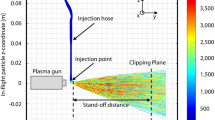

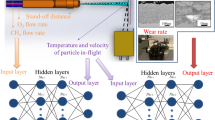

During plasma spray process, many intrinsic operating parameters allow tailoring in-flight particle characteristics (temperature and velocity) by controlling the plasma jet properties, thus affecting the final coating characteristics. Among them, plasma flow mass enthalpy, flow thermal conductivity, momentum density, etc. result from the selection of extrinsic operating parameters such as the plasma torch nozzle geometry, the composition and flow rate of plasma forming gases, the arc current intensity, beside the coupled relationships between those operating parameters make difficult in a full prediction of their effects on coating properties. Moreover, temporal fluctuations (anode wear for example) require “real time” corrections to maintain particle characteristic to targeted values. An expert system is built to optimize and control some of the main extrinsic operating parameters. This expert system includes two parts: (1) an artificial neural network (ANN) which predicts an extrinsic operating window and (2) a fuzzy logic controller (FLC) to control it. The paper details the general architecture of the system, discusses its limits and the typical characteristic times. The result shows that ANN can predict the characteristics of particles in-flight from coating porosity within maximal error 3 and 2 % in temperature and velocity respectively. And ANN also can predict the operating parameters from in-flight particle characteristics with maximal error 2.34, 4.80 and 8.66 % in current intensity, argon flow rate, and hydrogen flow rate respectively.

Similar content being viewed by others

References

Fauchais P, Vardelle M, Vardelle A, Bianchi L (1996) Plasma spray: study of the coating generation. Ceram Int 22(4):295–303

Coudert JF, Planche MP, Fauchais P (1996) Characterization of dc plasma torch voltage fluctuations. Plasma Chem Plasma Process 16(1):211S–227S

Bisson JF, Gauthier B, Moreau C (2003) Effect of plasma fluctuations on in-flight particle parameters. ASM Int 12(1):38–43

Heberlein JV (2002) Electrode phenomena in DC arcs and their influence on plasma torch design. High Temp Mater Process (New York) 6(3):321–338

Szente RN, Munz RJ, Drouet MG (1992) Electrode erosion in plasma troches. Plasma Chem Plasma Process 12(3):327–343

Rigot D, Delluc G, Pateyron B, Coudert JF, Fauchais P, Wigren J (2003) Transient evolution and shifts of signals emitted by a DC plasma gun (type PTF4). High Temp Mater Process (New York) 7(2):175–185

Guessasma S, Montavon G, Coddet C (2004) Neural computation to predict in-flight particle characteristic dependences from processing parameters in the APS process. ASM International 13(4):570–585

Kanta AF, Montavon G, Berndt CC, Planche MP, Coddet C (2011) Intelligent system for prediction and control: application in plasma spray process. Expert Syst Appl 38(1):260–271

Bhadeshia HKDH (1999) Neural networks in materials science. Iron Steel Inst Jpn Int 39(10):966–979

Guessasma S, Montavon G, Gougeon P, Coddet C (2003) Designing expert system using neural computation in view of the control of plasma spray processes. Mater Des 24(7):497–502

Kanta AF, Montavon G, Planche MP, Coddet C (2009) Artificial neural networks implementation in plasma spray process: prediction of power parameters and in-flight particle characteristics vs. desired coating structural attributes. Surf Coat Technol 203(22):3361–3369

Kanta AF, Montavon G, Planche MP, Coddet C (2008) In-flight particle characteristics control by implementing a fuzzy logic controller. Surf Coat Technol 202(18):4479–4482

Jean MD, Lin BT, Chou JH (2006) Design of a fuzzy logic approach for optimization reinforced zirconia depositions using plasma sprayings. Surf Coat Technol 201(6):3129–3138

Jean MD, Lin BT, Chou JH (2008) Application of an artificial neural network for simulating robust plasma sprayed zirconia coatings. J Am Ceram Soc 91(5):1539–1547

Datta S, Pratihar DK, Bandyopadhyay PP (2012) Modeling of input-output relationships for a plasma spray coating process using soft computing tools. Appl Soft Comput 12(11):3356–3368

Wang L, Fang JC, Zhao ZY, Zeng HP (2007) Application of backward propagation network for forecasting hardness and porosity of coatings by plasma spraying. Surf Coat Technol 201(9–11):5085–5089

Syed AA, Denoirjean A, Hannoyer B, Fauchais P, Denoirjean P, Khan AA, Labbe JC (2005) Influence of substrate surface conditions on the plasma sprayed ceramic and metallic particles flattening. Surf Coat Technol 200(7):2317–2331

Choudhury TA, Hosseinzadeh N, Berndt CC (2011) Artificial neural network application for predicting in-flight particle characteristics of atmospheric plasma spray process. Surf Coat Technol 205(21–22):4886–4895

Monicka JG, Sekhar NO, Kumar KR (2011) Performance evaluation of membership functions on fuzzy logic controlled AC voltage controller for speed control of induction motor drive. Int J Comput Appl 13(5):8–12

Mamdani EH (1974) Application of fuzzy algorithms for control of simple dynamic plant. Proc Inst Electr Eng 121(12):1585–1588

Jean MD, Lin BT, Chou JH (2007) Design of a fuzzy logic approach based on genetic algorithms for robust plasma-sprayed zirconia depositions. Acta Mater 55(6):1985–1997

Sarikaya O (2005) Effect of the substrate temperature on properties of plasma sprayed Al2O3 coatings. Mater Des 26(1):53–57

Acknowledgments

Authors give a great thank to the support from the program Marie-Curie for IPACTS (International Partnership for Advanced Coatings by Thermal Spraying) under Grant # 268696.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Liu, T., Planche, M.P., Kanta, A.F. et al. Plasma Spray Process Operating Parameters Optimization Based on Artificial Intelligence. Plasma Chem Plasma Process 33, 1025–1041 (2013). https://doi.org/10.1007/s11090-013-9475-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11090-013-9475-3