Abstract

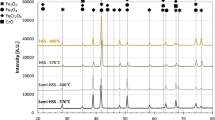

The high temperature isothermal oxidation behaviour of work rolls and the oxide structures resulting from this process are presented. Oxidation of these alloys at 615 °C under various environmental conditions resulted in the formation of oxide crystals of different morphologies, depending on the chemical composition of the alloys and the gases present in the oxidant atmosphere. Particularly, the surface oxidation of high speed steel and high chromium iron for work rolls in hot strip mills included the formation of whiskers, platelets, and crystallites. The composition of the oxidant atmosphere also influenced the oxidation rate of the specimens by promoting the formation of protective or non-protective oxides. The reasons for the development of the different oxide morphologies and the effect that the oxides formed on the surface exert on the behaviour of important tribological variables present in the hot rolling of steel such as friction are discussed.

Similar content being viewed by others

References

N. Bay and T. Wanheim, Real area of contact and friction stress at high pressure sliding contact. Wear 38, 201 (1976).

J. H. Beynon, Tribology of hot metal forming. Tribology International 31, 73 (1998).

O. Kato, H. Yamamoto, M. Ataka, and K. Nakajima, Mechanisms of surface deterioration of roll for hot strip rolling. ISIJ International 32, 1216 (1992).

F. H. Stott and G. C. Wood, Tribology International 11, 211 (1978).

F. H. Stott, The role of oxidation in the wear of alloys. Tribology International 31, 61 (1998).

M. P. Guerrero, C. R. Flores, A. Pérez, and R. Colás, Modelling heat transfer in hot rolling work rolls. Journal of Materials Processing Technology 94, 52 (1999).

A. Molinari, G. Straffelini, A. Tomasi, A. Biggi, and G. Corbo, Influence of microstructure and chromium content on oxidation behaviour of spin cast high speed steels. Materials Science and Technology 17, 425 (2001).

N. F. Garza-Montes-de-Oca, R. Colás, and W. M. Rainforth, High temperature oxidation of a work roll grade high speed steel. Oxidation of Metals 76, 451 (2011).

A. Bedolla-Jacuinde and W. M. Rainforth, The wear behaviour of high-chromium white cast irons as a function of silicon and mischmetal content. Wear 250, 449 (2001).

R. Peraldi and B. A. Pint, Effect of Cr and Ni contents on the oxidation behavior of ferritic and austenitic model alloys in air with water vapor. Oxidation of Metals 61, 463 (2004).

N. K. Othman, J. Zhang, and D. J. Young, Water vapour effects on Fe–Cr alloy oxidation. Oxidation of Metals 73, 337 (2010).

N. Bertrand, C. Desgranges, D. Poquillon, M. C. Lafont, and D. Monceau, Oxidation of Metals 73, 139 (2010).

N. W. Ashcroft and N. D. Mermin, Solid State Physics,Chapter 30, (Brooks/Cole Belmont, CA, 1976), p. 637.

J. Ehlers, D. J. Young, E. J. Smaardijk, A. K. Tyagi, H. J. Penkalla, L. Singheiser, and W. J. Quadakkers, Iron oxidation at low temperature (260–500° C) in air and the effect of water vapor. Corrosion Science 48, 3428 (2006).

D. Laverde, T. Gómez-Acebo, and F. Castro, Continuous and cyclic oxidation of T91 ferritic steel under steam. Corrosion Science 46, 613 (2004).

H. Asteman, J. -E. Svensson, L. -G. Johansson, and M. Norell, Indication of chromium oxide hydroxide evaporation during oxidation of 304 L at 873 K in the presence of 10 % water vapor. Oxidation of Metals 52, 95 (1999).

A. I. Kahveci and G. E. Welsch, Oxidation of Fe-3 %wt Cr alloy. Oxidation of Metals 26, 213 (1986).

Y. Chang and F. Wei, High temperature oxidation of low alloys steels. Materials Science 24, 14 (1989).

R. Tallman and E.Gulbransen, Crystal morphology and mechanisms of growth of α-Fe2O3 whiskers on iron Technical Report No.1, (Office of Naval Research Materials Science Division, Washington, DC, 1966).

C. Santafe′ and C. Borgianni, Oxidation of metals 9(5), 415 (1975).

R. N. Durham, B. Gleeson, and D. J. Young, Factors affecting chromium carbide precipitate dissolution during alloy oxidation. Oxidation of Metals 50, 139 (1998).

C. Rodenburg and W. M. Rainforth, A quantitative analysis of the influence of carbides size distributions on wear behaviour of high speed steel in dry rolling/sliding contact. Acta Materialia 55, 2443 (2007).

N. F. Garza-Montes-de-Oca and W. M. Rainforth, Wear mechanisms experienced by a work roll grade high speed steel under different environmental conditions. Wear 267, 441 (2009).

D. N. Hanlon, W. M. Rainforth, and C. M. Sellars, The rolling/sliding wear response of conventionally processed and spray formed high chromium content cast iron at ambient and elevated temperature. Wear 225, 587 (1999).

Acknowledgments

The authors would like to thank the National Council for Science and Technology in Mexico (CONACyT), the PROMEP program for lecturer development and, Universidad Autónoma de Nuevo Leon (UANL) for the support provided to develop this work.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Garza-Montes-de-Oca, N.F., Ramírez-Ramírez, J.H., Alvarez-Elcoro, I. et al. Oxide Structures Formed During the High Temperature Oxidation of Hot Mill Work Rolls. Oxid Met 80, 191–203 (2013). https://doi.org/10.1007/s11085-013-9404-0

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11085-013-9404-0