Abstract

The recent availability of a wide range of additively manufactured materials has facilitated the translation from prototype-limited to application-ready 3D printed components. As such, additively manufactured materials deployed in dynamic environments require extensive characterization to elucidate and optimize performance. This research evaluates the dynamic response of fused filament fabrication and vat photopolymerization printed polymers as a function of temperature. Dynamic mechanical analysis is used to extract the viscoelastic properties of several generations of samples exhibiting a range of thermomechanical behavior, highlighting the stiffness and dam** characteristics. A modified stiffness–temperature model supports the experimental characterization and provides additional insight concerning the molecular motion occurring over each thermal transition. The insights from the analysis were collated into a case study that leverages their dynamic characteristics in a multimaterial application. The outcomes from this research assimilate a framework that defines the temperature operating range and broadens the design envelope for these additive manufacturing materials.

Similar content being viewed by others

Data Availability

Data will be made available upon request to the corresponding author.

References

Adibeig, M.R., et al.: Quasi-static simulation and fatigue life estimation of fused filament fabrication of polylactic acid specimens using finite element method. J. Manuf. Process. 106, 202–213 (2023)

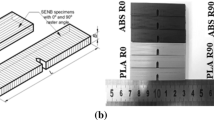

Ahn, S.H., et al.: Anisotropic material properties of fused deposition modeling ABS. Rapid Prototy** J. 8(4), 248–257 (2002)

Alarifi, I.M.: Investigation of the dynamic mechanical analysis and mechanical response of 3D printed nylon carbon fiber composites with different build orientation. Polym. Compos. 43(8), 5353–5363 (2022)

Alasfar, R.H., et al.: A review on the modeling of the elastic modulus and yield stress of polymers and polymer nanocomposites: effect of temperature, loading rate and porosity. Polymers 14(3), 360 (2022)

Anandhan, S., et al.: Novel thermoplastic elastomers based on acrylonitrile-butadiene-styrene terpolymer (ABS) from waste computer equipment and nitrile rubber. Rubber Chem. Technol. 76(5), 1145–1163 (2003)

Anastasio, R., et al.: Characterization of ultraviolet-cured methacrylate networks: from photopolymerization to ultimate mechanical properties. Macromolecules 52(23), 9220–9231 (2019)

Andrady, A.L., et al.: Effects of increased solar ultraviolet radiation on materials. J. Photochem. Photobiol. B, Biol. 46(1), 96–103 (1998)

Andrady, A., et al.: Effects of UV radiation on natural and synthetic materials. Photochem. Photobiol. Sci. 22, 1–26 (2023)

Ashby, M.F., Jones, D.R.H.: An Introduction to Microstructures, Processing and Design. No Title (1986)

Bakhtiari, H., Aamir, M., Tolouei-Rad, M.: Effect of 3D printing parameters on the fatigue properties of parts manufactured by fused filament fabrication: a review. Appl. Sci. 13(2), 904 (2023)

Boyer, R.F.: The relation of transition temperatures to chemical structure in high polymers. Rubber Chem. Technol. 36(5), 1303–1421 (1963)

Brans, K.: 3D printing, a maturing technology. In: IFAC Proceedings Volumes, vol. 46, pp. 468–472 (2013)

Brighenti, R., et al.: Mechanical characterization of additively manufactured photopolymerized polymers. Mech. Adv. Mat. Struct. 30(9), 1853–1864 (2023)

Camelio, P., et al.: Glass transition temperature calculations for styrene derivatives using the energy, volume, and mass model. Macromolecules 31(7), 2305–2311 (1998)

Casado, J., et al.: 3D printable hybrid acrylate-epoxy dynamic networks. Eur. Polym. J. 173, 111256 (2022)

Chantarapanich, N., et al.: Study of the mechanical properties of photo-cured epoxy resin fabricated by stereolithography process. Songklanakarin J. Sci. Technol. 35(1) (2013)

Chhikara, K., et al.: Development and effectiveness testing of a novel 3D-printed multi-material orthosis in nurses with plantar foot pain. Prosthesis 5(1), 73–87 (2023)

Christensen, R., Waals, F.: Effective stiffness of randomly oriented fibre composites. J. Compos. Mater. 6(4), 518–532 (1972)

Cotten, G., Schneider, W.: Transition temperatures in copolymers of acrylonitrile. Kolloid-Z. Z. Polym. 192, 16–21 (1963)

Cuan-Urquizo, E., et al.: Characterization of the mechanical properties of FFF structures and materials: a review on the experimental, computational and theoretical approaches. Materials 12(6), 895 (2019)

Curtis, P., Bader, M., Bailey, J.: The stiffness and strength of a polyamide thermoplastic reinforced with glass and carbon fibres. J. Mater. Sci. 13, 377–390 (1978)

Dakshinamurthy, D., Gupta, S.: A study on the influence of process parameters on the viscoelastic properties of ABS components manufactured by FDM process. J. Inst. Eng. (India), Ser. C 99(2), 133–138 (2018)

Deng, X., et al.: Mechanical properties optimization of poly-ether-ether-ketone via fused deposition modeling. Materials 11(2), 216 (2018)

Desai, S.M., Sonawane, R.Y., More, A.P.: Thermoplastic polyurethane for three-dimensional printing applications: a review. Polym. Adv. Technol. 34(7), 2061–2082 (2023)

Dizon, J.R.C., et al.: Mechanical characterization of 3D-printed polymers. Addit. Manuf. 20, 44–67 (2018)

Dulieu-Barton, J., Fulton, M.: Mechanical properties of a typical stereolithography resin. Strain 36(2), 81–87 (2000)

Feng, J., et al.: Revealing molecular mechanisms of colorless transparent polyimide films under photo-oxidation. Polym. Degrad. Stab. 210, 110294 (2023)

Forster, M.J.: Glass transition temperature of Nylon 6. Tex. Res. J. 38(5), 474–480 (1968)

Frick, A., Rochman, A.: Characterization of TPU-elastomers by thermal analysis (DSC). Polym. Test. 23(4), 413–417 (2004)

Gómez-García, D., et al.: Machinability of 3D printed peek reinforced with short carbon fiber. Comp. Part C Open Access 12, 100387 (2023)

Gordon, G.A.: Glass transition in nylons. J. Polym. Sci., Part A-2, Polym. Phys. 9(9), 1693–1702 (1971)

Greco, R., Nicolais, L.: Glass transition temperature in nylons. Polymer 17(12), 1049–1053 (1976)

Gunter, E.: Designing with Plastics. Hanser Verlag, Munich (2006)

Gurjar, D., Sharma, S., Sarkar, M.: A review on testing methods of recycled acrylonitrile butadiene-styrene. In: Materials Today: Proceedings, vol. 5, pp. 28296–28304 (2018)

Hague, R., et al.: Materials analysis of stereolithography resins for use in rapid manufacturing. J. Mater. Sci. 39(7), 2457–2464 (2004)

Huynh, N.U., et al.: Property-map of epoxy-treated and as-printed polymeric additively manufactured materials. Int. J. Mech. Sci. 181, 105767 (2020)

Kim, D.S., Seo, W.H.: Ultraviolet-curing behavior and mechanical properties of a polyester acrylate resin. J. Appl. Polym. Sci. 92(6), 3921–3928 (2004)

Kim, K., et al.: 3D printing of multiaxial force sensors using carbon nanotube (CNT)/thermoplastic polyurethane (TPU) filaments. Sens. Actuators A, Phys. 263, 493–500 (2017)

Kraus, G., Childers, C., Gruver, J.: Properties of random and block copolymers of butadiene and styrene. I. Dynamic properties and glassy transition temperatures. J. Appl. Polym. Sci. 11(8), 1581–1591 (1967)

Kuenstler, A.S., et al.: Vat photopolymerization additive manufacturing of tough, fully recyclable thermosets. ACS Appl. Mater. Interfaces 15(8), 11111–11121 (2023)

Kumar, S., et al.: Fused filament fabrication: a comprehensive review. J. Thermoplast. Compos. Mater. 36(2), 794–814 (2023)

Lakes, R.S.: Viscoelastic Solids (1998). CRC Press, Boca Raton (2017)

Lantean, S., et al.: Magnetoresponsive devices with programmable behavior using a customized commercial stereolithographic 3D printer. Adv. Mater. Technol. 7(11), 2200288 (2022)

Laureto, J.J., Pearce, J.M.: Anisotropic mechanical property variance between ASTM D638-14 type I and type IV fused filament fabricated specimens. Polym. Test. 68, 294–301 (2018)

Ligon, S.C., et al.: Polymers for 3D printing and customized additive manufacturing. Chem. Rev. 117(15), 10212–10290 (2017)

Mahieux, C.A., Reifsnider, K.L.: Property modeling across transition temperatures in polymers: a robust stiffness–temperature model. Polymer 42(7), 3281–3291 (2001)

Malley, S., Newacheck, S., Youssef, G.: Additively manufactured multifunctional materials with magnetoelectric properties. Addit. Manuf. 47, 102239 (2021)

Menard, K.P., Menard, N.: Dynamic Mechanical Analysis. CRC Press, Boca Raton (2020)

Miller, M.L.: The structure of polymers (1966). (No Title)

Naik, D.L., Kiran, R.: On anisotropy, strain rate and size effects in vat photopolymerization based specimens. Additive Manufacturing 23, 181–196 (2018)

Namvar, N., et al.: Bio-inspired design, modeling, and 3D printing of lattice-based scale model scooter decks. Int. J. Adv. Manuf. Technol. 126(7), 2887–2903 (2023)

Naveen, R., et al.: An investigation on effect of ultraviolet (UV) rays on mechanical properties of epoxy laminates. Mater. Today Proc. (2023)

Nugraha, A.D., Syahril, M., Muflikhun, M.A.: Excellent performance of hybrid model manufactured via additive manufacturing process reinforced with GFRP for sport climbing equipment. Heliyon 9(3), e14706 (2023)

Onwubolu, G.C., Rayegani, F.: Characterization and optimization of mechanical properties of ABS parts manufactured by the fused deposition modelling process. Int. J. Manuf. Eng. 2014, 1–13 (2014)

Pachauri, S., Gupta, N.K., Gupta, A.: Influence of 3D printing process parameters on the mechanical properties of polylactic acid (PLA) printed with fused filament fabrication: experimental and statistical analysis. Int. J. Interact. Des. Manuf., 1–19 (2023)

Patterson, A.E., et al.: Fracture testing of polymer materials processed via fused filament fabrication: a survey of materials, methods, and design applications. Prog. Addit. Manuf. 6(4), 765–780 (2021)

Platzer, N.: Progress in polymer engineering. Ind. Eng. Chem. 61(5), 10–30 (1969)

Prashar, G., Vasudev, H., Bhuddhi, D.: Additive manufacturing: expanding 3D printing horizon in industry 4.0. Int. J. Interact. Des. Manuf. 17(5), 2221–2235 (2023)

Ramya, A., Vanapalli, S.L.: 3D printing technologies in various applications. Int. J. Mech. Eng. Technol. 7(3), 396–409 (2016)

Randhawa, K.S., Patel, A.: The effect of environmental humidity/water absorption on tribo-mechanical performance of polymers and polymer composites–a review. Ind. Lubr. Tribol. 73(9), 1146–1158 (2021)

Reich, M.J., et al.: Mechanical properties and applications of recycled polycarbonate particle material extrusion-based additive manufacturing. Materials 12(10), 1642 (2019)

Riechert, V., et al.: Rheological properties and UV photo-oxidation of montmorillonite-filled random propylene–ethylene copolymers. Polym. Bull. 80(4), 3981–4004 (2023)

Rodríguez, J.F., Thomas, J.P., Renaud, J.E.: Mechanical behavior of acrylonitrile butadiene styrene (ABS) fused deposition materials. Experimental investigation. Rapid Prototy** J. 7(3), 148–158 (2001)

Sabatini, F., et al.: A thermal analytical study of LEGO® bricks for investigating light-stability of ABS. Polymers 15(15), 3267 (2023)

Sărăndan, S.O.: Contributions regarding the development of cellular structures destined for sports equipment (2022)

Schwaar, C.: 3D Printed Shoes: The Cream of the Crop of 2023 (2023)

Senna, S.: Design, 3D printing and characterisation of bending-dominated lattice structures for energy absorption in sports equipment (2019)

Shojib Hossain, M., et al.: Improving tensile mechanical properties of FDM-manufactured specimens via modifying build parameters. In: 2013 International Solid Freeform Fabrication Symposium (2013). University of Texas at Austin

Shojib Hossain, M., et al.: Improved mechanical properties of fused deposition modeling-manufactured parts through build parameter modifications. J. Manuf. Sci. Eng. 136(6), 061002 (2014)

Silver, F.H., Gonzalez-Mercedes, M., Mesica, A.: A rapid method to noninvasively measure the viscoelastic properties of synthetic polymers using mechanical vibrations and photonics. Photonics 9(12), 925 (2022)

Sola, A., et al.: Open challenges in tensile testing of additively manufactured polymers: a literature survey and a case study in fused filament fabrication. Polym. Test. 117, 107859 (2023)

Song, Y., et al.: An overview of selective laser sintering 3D printing technology for biomedical and sports device applications: processes, materials, and applications. Opt. Laser Technol. 171, 110459 (2024)

Sood, A.K., Ohdar, R.K., Mahapatra, S.S.: Experimental investigation and empirical modelling of FDM process for compressive strength improvement. J. Adv. Res. 3(1), 81–90 (2012)

Stribeck, N., et al.: Structure and mechanical properties of an injection-molded thermoplastic polyurethane as a function of melt temperature. Macromol. Chem. Phys. 212(20), 2234–2248 (2011)

Svetlana, T., et al.: Flexural quasi-static and fatigue behaviours of fused filament deposited PA6 and PA12 polymers. Int. J. Adv. Manuf. Technol. 117(7), 2041–2048 (2021)

Tan, L.J., Zhu, W., Zhou, K.: Recent progress on polymer materials for additive manufacturing. Adv. Funct. Mater. 30(43), 2003062 (2020)

Uddin, M.S., et al.: Evaluating mechanical properties and failure mechanisms of fused deposition modeling acrylonitrile butadiene styrene parts. J. Manuf. Sci. Eng. 139(8), 081018 (2017)

Uddin, K.Z., et al.: Gradient optimization of multi-layered density-graded foam laminates for footwear material design. J. Biomech. 109, 109950 (2020)

Vidakis, N., Petousis, M., Kechagias, J.: A comprehensive investigation of the 3D printing parameters’ effects on the mechanical response of polycarbonate in fused filament fabrication. Prog. Addit. Manuf. 7(4), 713–722 (2022)

Wang, Y., et al.: Acoustic-assisted 3D printing based on acoustofluidic microparticles patterning for conductive polymer composites fabrication. Addit. Manuf. 60, 103247 (2022)

Wineman, A.S., Rajagopal, K.R.: Mechanical Response of Polymers: An Introduction. Cambridge University Press, Cambridge (2000)

Wittbrodt, B., Pearce, J.M.: The effects of PLA color on material properties of 3-D printed components. Addit. Manuf. 8, 110–116 (2015)

**ang, Y., et al.: Mechanical characterization and constitutive modeling of visco-hyperelasticity of photocured polymers. Addit. Manuf. 36, 101511 (2020)

Yadav, A., et al.: Fused filament fabrication: a state-of-the-art review of the technology, materials, properties and defects. Int. J. Interact. Des. Manuf. 17(6), 2867–2889 (2023)

Yanagihara, Y., et al.: Relationship between modulus and structure of annealed thermoplastic polyurethane. Mater. Today Commun. 2, e9–e15 (2015)

Yankin, A., et al.: Optimization of printing parameters to enhance tensile properties of ABS and nylon produced by fused filament fabrication. Polymers 15(14), 3043 (2023)

Yin, Z.N., Fan, L.F., Wang, T.J.: Experimental investigation of the viscoelastic deformation of PC, ABS and PC/ABS alloys. Mater. Lett. 62(17), 2750–2753 (2008)

Yousif, E., et al.: Photo-physical and morphological study of polymers: a review. Phys. Chem. Res. 11(2), 409–424 (2023)

Youssef, G.: Applied Mechanics of Polymers: Properties, Processing, and Behavior. Elsevier, Amsterdam (2021)

Youssef, G., et al.: Multifunctional fused deposition modeled acrylonitrile butadiene styrene-based structures with embedded conductive channels. J. Eng. Mater. Technol. 143(1), 011001 (2021)

Zahir Uddin, K., et al.: In-plane Density Gradation of Shoe Midsoles for Optimized Cushioning Performance (2024). e-prints, ar**v:2401.06940

Zaldivar, R., et al.: Influence of processing and orientation print effects on the mechanical and thermal behavior of 3D-printed ULTEM® 9085 material. Addit. Manuf. 13, 71–80 (2017)

Zolfagharian, A., et al.: Custom shoe sole design and modeling toward 3D printing. Int. J. Bioprinting 7(4) (2021)

Acknowledgements

The authors acknowledge the support by the National Science Foundation under Grant No. 2035663. The authors are also grateful for internal funding from San Diego State University. Funding from the Department of Defense (W911NF1410039, W911NF1810477, and W911NF2210199) is also acknowledged. Support from San Diego State University is also acknowledged.

Funding

The research leading to these results is funded by the National Science Foundation under Grant No. 2035663 and from the Department of Defense (W911NF1410039, W911NF1810477, and W911NF2210199). The authors are also grateful for internal funding and support from San Diego State University. The authors have no competing interests to declare.

Author information

Authors and Affiliations

Contributions

All authors were responsible for writing (review and editing), data curation, formal analysis, investigation, visualization, figure preparation, and methodology. G.Y. is responsible for writing the original draft, conceptualization, project administration, resources, and funding acquisition.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Singh, A., Chen, M. & Youssef, G. Comparative characterization of the viscoelastic properties of additive manufacturing polymers. Mech Time-Depend Mater (2024). https://doi.org/10.1007/s11043-024-09710-7

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s11043-024-09710-7