Abstract

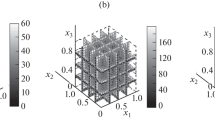

To preheat water for moistening a sinter charge, it is proposed to use a recuperative water heater installed in the gas collector of a sinter machine in the zone of the last wind boxes where the temperature of the exhaust gas reaches the maximum, which allows the maximum effect of water heating. The established dependence of the difference between the final and initial temperature of the charge on its initial temperature indicates that the water heating system in sinter production will be the most efficient at sinter charge temperatures close to 0 °C. Finite-element models for analysis of gas dynamics, heat transfer, and water heating in recuperative water heaters by the exhaust gas in the collector of a sinter machine have been developed. Diagrams of the distribution of the temperature of the fluids and the flow-average temperature of water at the collector outlet in planes located along and across the flow of the exhaust gases are plotted. It is established that the heating of the heat-transfer fluid in the water heater with the tubing parallel to the gas flow from the wind box is more intensive, the outlet water temperature being higher by 12.6 °C compared with the case where the tubing is perpendicular to the gas flow in the collector. The developed method of simulating water heating by the heat of the exhaust gas is intended to determine the rational parameters and design features of the recuperative water heater installed in the collector of a sinter machine.

Similar content being viewed by others

References

Korotich VI, Frolov Bezdezhskii YATN (2003) Agglomeration sintering of ore materials. GOU VPO UGTU-UPI, Ekaterinburg

Seetharaman S (ed) (2014) Industrial processes vol 3. Treatise on Process Metallurgy, Elsevier

Vegman EF et al (2004) Iron metallurgy. Akademkniga, Moscow

Krasnikov KS (2018) Mathematical modeling of slag dynamics on the surface of metalic melt during inert gas blowing. Vestn Kherson Nats Tekhn Univ 2(65):190–194

Yu A (2016) Frolov, agglomeration sintering: technology, thermal engineering, control, ecology. Metallurgizdat, Moscow

Bazilevich SV, Vegman VF (1967) Agglomeration sintering. Metallurgizdat, Moscow

Petrushov SN (2006) Modern agglomeration sintering process. DonGTU, Alchevsk

Smorodinnikov AV, Gubanov VI (1985) Intensification of the pelletizing of iron ore raw materials. Inst. Uralmekhangobr, Sverdlovsk

Toda H, Kato K (1984) Theoretical investigation of sintering process. Trans ISIJ 24:178–186

Saveliev S, Kondratenko M (2020) Analysis and synthesis of factors determining the sintering speed of sinter charge. In: Proc. Int. Conf. on Sustainable Futures: Environmental, Technological, Social and Economic Matters (ICSF 2020), vol 166. https://doi.org/10.1051/e3sconf/202016606010

Frolov YA, Aggarwal N, Polotskii LI (2017) Study of flue-gas recirculation sintering. Metallurgist 61(7–8):629–637

Mühlböck M, Gerald N, Edmund F (2015) Recirculation of sinter off gas—a selective approach. Anais Dos Seminários De Redução Minério De Ferro E Aglomeração Rio De Janeiro 45(45):154–163

Uvarov VV (2017) Assessment of the efficiency of different methods of heating of a sinter charge in the conditions of Ural Steel. In: Technologies of metallurgy, mechanical engineering, and materials processing, vol 16. MGTU im. G. I. Nosova, Magnitogorsk, pp 4–10

Shapovalov AN (2018) Using the heat of a sinter for additional heating of the sinter charge. Teor Tekhnol Metall Proizv 4(27):32–36

Mathur GP, Subra GVM, Narayanan PIA (1957) Sintering of iron ore fines, and raw materials for Bhilai Steel Plant. Indian Min J (special issue):281–303

Mishchenko IM (2012) Ferrous metallurgy and environmental protection. DonNTU, Donetsk

Loitsyanskii LG (1987) Fluid mechanics. Nauka, Moscow

Bejan A (2013) Convection heat transfer. John Wiley & Sons, Hoboken

Baskakov AP (ed) (1991) Thermal engineering. Energoatomizdat, Moscow

Dogra S, Willis J (2023) SOLIDWORKS simulation 2023: a power guide for beginners and intermediate users. CADArtifex

Uvarov VA et al (2015) “Methods for calculating the amount of heat in exhaust gases,” Mezhdunar. Nauch.-Issled. Zh., No. 8 (39). https://research-journal.org/archive/8-39-2015-september/metodiki-raschyota-kolichestva-tepla-v-uxodyashhix-gazax

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated from Metallurg, No. 11, 2023, pp. 101–105. https://doi.org/10.52351/00260827_2023_11_101.

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Vlasenko, D.A. Simulation of heat-transfer conditions and development of a method for heating a sinter charge with water preheated using the heat of exhaust gases. Metallurgist (2024). https://doi.org/10.1007/s11015-024-01666-w

Received:

Revised:

Accepted:

Published:

DOI: https://doi.org/10.1007/s11015-024-01666-w