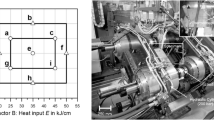

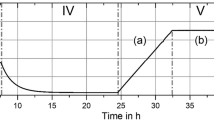

This work investigates the influence exerted by the combined thermal effects of aluminothermic welding and arc welding with solid wire on the residual stress in the plate material. A mathematical model is constructed based on the Prandtl-Reuss model, where Hooke’s law is substituted with the Duhamel- Neumann law. It is considered that the deformations are low. Irreversible deformations develop when the von Mises yield criterion is satisfied, which includes the Johnson-Cook strain hardening function. In order to determine the parameters of this function, a number of tensile tests are carried out on parent metal samples and welding material obtained by electric arc welding with solid section wire or by a combined method of aluminothermic welding. The thermal effects are modeled by a double comet- shaped ellipsoid proposed by Goldak. For the combined welding method, the additional thermal effects from the exothermic reaction of the aluminothermic filler material and the lower heat dissipation due to the formation of a slag crust are considered. By analyzing the residual stresses, it is concluded that the use of flux-cored wire with aluminothermic filler in automatic electric arc welding results in lower levels of residual stresses, thereby positively affecting the subsequent operation of the welded structure.

Similar content being viewed by others

References

L. Li, G. Mi, and C. Wang, “A comparison between induction pre-heating and induction post-heating of laser-induction hybrid welding on S690QL steel,” J. Manuf., 43, 276–291 (2019); https://doi.org/10.1016/j.jmapro.2019.05.003.

M. Charkhi and D. Akbari, “Experimental and numerical investigation of the effects of the pre-heating in the modification of residual stresses in the repair welding process,” Int. J. Press. Vessels Pip., 171, 79–91 (2019); https://doi.org/10.1016/j.ijpvp.2019.02.006.

S. Ji, Z. Li, Y. Wang, and L. Ma, “Joint formation and mechanical properties of back heating assisted friction stir welded Ti–6Al–4V alloy,” Mater. Des., 113, 37–46 (2017); https://doi.org/10.1016/j.matdes.2016.10.012.

D. Sergejevs and S. Mikhaylovs, “Analysis of factors affecting fractures of rails welded by alumino-thermic welding,” Transp. Probl.: An Intern. Sci. J., 3(4–2), 33–37 (2008).

V. A. Kargin, L. B. Tikhomirova, M. S. Galay, and Y. S. Kuznetsova, “Improving service properties of welded joints produced by aluminothermic welding,” Weld. Int., 29, No. 2, 155–157 (2015).

A. L. Manakov, A. D. Abramov, A. S. Ilinykh, M. S. Galay, and Je. S. Sidorov, “Improvement of aluminothermic welding on the basis of the experimentally-theoretical research of welding seam cooling process,” J. Phys.: Conf. Ser., 1050, 012051 (2018).

B. L. Josefson., R. Bisschop, M. Messaadi, and J. Hantusch, “Residual stresses in thermite welded rails: significance of additional forging,” Weld.World, 64, 1195–1212 (2020).

H. L. Li, D. Liu, N. Guo, H. Chen, Y. P. Du, and J. C. Feng, “The effect of alumino-thermic addition on underwater wet welding process stability,” J. Mater. Process. Technol., 245, 149–156 (2017).

J. Chuanbao, Z. Tao, S. Yu. Maksimov, and Y. **n, “Spectroscopic analysis of the arc plasma of underwater wet flux-cored arc welding,” J. Mater. Process. Technol., 213, 1370–1377 (2013).

S. Weiss, I. Riehl, J. Hantusch, and U. Gross, “Numerical investigation on the crucible discharge of steel and slag during the aluminothermic welding process,” Arch. Metall. Mater., 63, No. 1, 173–180 (2018).

X. Wang, A. Wan, J. Wang, L. Zhu, and H. Ruan, “Anomalous sudden drop of temperature-dependent Young’s modulus of a plastically deformed duplex stainless steel,” Mater. Des., 181, 108071 (2019).

H. Xue, D. Liu, R. Ge, L. Pan, and W. Peng, “The delay loop phenomenon in high temperature elasticity modulus test by in-situ ultrasonic measurements,” Measurement, 160, 107833 (2020).

B. A. Latella and S. R. Humphries, “Young’s modulus of a 2.25Cr–1Mo steel at elevated temperature,” Scr. Mater., 51, 635–639 (2004).

L.-E. Lindgren and J. Gyhlesten, “Back Elastic properties of ferrite and austenite in low alloy steels versus temperature and alloying,” Material., 5, 100193 (2019).

M. Rokilan and M. Mahendran, “Elevated temperature mechanical properties of cold-rolled steel sheets and cold formed steel sections,” J. Constr. Steel Res., 167, 105851 (2020).

J. H. Sung, J. H. Kim, and R. H. Wagoner, “A plastic constitutive equation incorporating strain, strain-rate, and temperature,” Intern. J. Plast., 26, 1746–1771 (2010).

W. Wang, Y. Ma, M. Yang, P. Jiang, F. Yuan, and X. Wu, “Strain rate effect on tensile behavior for a high specific strength steel: From quasi-static to intermediate strain rates,” Trans. Indian Inst. Met., 8, No. 11 (2018); 10.3390/ met8010011.

A. S. Savinykh, G. V. Garkushin, S. V. Razorenov, S. Wolf, and L. Kruger, “Influence of the temperature-induced martensiticaustenitic transformation on the strength properties of high-alloy steels under dynamic loading,” Combust. Explos. Shock Waves, 51, 124–129 (2015).

V. Tarigopula, O. S. Hopperstad, M. Langseth, A. H. Clausen, and F. Hild, “A study of localization in dual-phase high strength steels under dynamic loading using digital image correlation and FE analysis,” Int. J. Solids Struct., 45, 601–619 (2008).

W. R. Wang, M. Li, C. W. He, X. C. Wei, D. Z. Wang, and H. B. Du, “Experimental study on high strain rate behavior of high strength 600–1000 MPa dual phase steels and 1200 MPa fully martensitic steels,” Mater. Des., 47, 510–521 (2013).

J. G. Qin, R. Chen, X. J. Wen, Y. L. Lin, M. Z. Liang, and F. Y. Lu, “Mechanical behaviour of dual-phase high-strength steel under high strain rate tensile loading,” Mater. Sci. Eng. A, 586, 62–70, (2013).

W. Mo´cko, A. Brodecki, and L. Kruszka, “Mechanical response of dual phase steel at quasi-static and dynamic tensile loadings after initial fatigue loading,” Mech. Mater., 92, 18–27 (2016).

S. Q. Xu, D. Ruan, J. H. Beynon, and Y. H. Rong, “Dynamic tensile behaviour of TWIP steel under intermediate strain rate loading,” Mater. Sci. Eng. A, 573, 132–140 (2013).

D. Y. Dong, Y. Liu, Y. L. Yang, J. F. Li, M. Ma, and T. Jiang, “Microstructure and dynamic tensile behavior of DP600 dual phase steel joint by laser welding,” Mater. Sci. Eng. A, 594, 17–25 (2014).

Y. Liu, D. Y. Dong, L. Wang, X. Chu, P. F. Wang, and M. M. **, “Strain rate dependent deformation and failure behavior of laser welded DP780 steel joint under dynamic tensile loading,” Mater. Sci. Eng. A, 627, 296–305 (2015).

Ye.Ye. Abashkin, S. G. Komarov, V. V. Zhilin, et al., Patent RF 2675876 (December 25, 2018).

E. E. Abashkin, S. G. Zhilin, and O. N. Komarov, “Structure formation of the heat-affected zone of the permanent joint made by the automatic submerged arc welding with the use of the flux-cored wire with thermite filler,” in: Proc. of the Intern. Conf. on Advanced Materials with Hierarchical Structure for New Technologies and Reliable Structures. AlPConf. Proc., 2167, 020001-1-020001-4 (2019); https://doi.org/10.1063/l.5131868.

J. A. Goldak and M. Akhlagi, Computational Welding Mechanics, New York, Springer Science & Business Media (2006).

E. I. Kazantsev, Industrial Furnaces. Handbook for Calculations and Design [in Russian], Metallurgy, Moscow (1975).

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated from Metallurg, Vol. 67, No. 6, pp. 85–93, June, 2023.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Tkacheva, A.V., Abashkin, E.E. Effect of Local Combined Thermal Action on Value and Distribution of Residual Stresses in Steel 20 Plate. Metallurgist 67, 826–838 (2023). https://doi.org/10.1007/s11015-023-01571-8

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11015-023-01571-8