Abstract

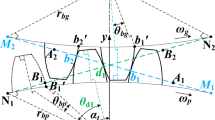

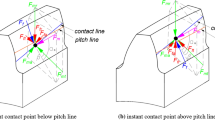

High-speed gear reducers are highly sensitive to vibration and noise, especially in new-energy vehicles. Hence, the current nonlinear dynamics model of gears does not fully consider the influence of tooth microstructure on backlash and friction. This study establishes a nonlinear friction dynamics model for a high-speed helical gear system, which includes time-varying dynamic backlash and friction coefficient based on the fractal characterization of tooth roughness. Furthermore, it investigates the influence of tooth surface roughness on the dynamic performance by taking into account the interaction between friction and vibration under Elastohydrodynamic Lubrication (EHL). Theoretical simulation results show that an increase in tooth roughness leads to an overall deterioration in the dynamic performance of the helical gear system; however, local optimization can also be observed. In the case of a dynamic tooth backlash, the amplitude of displacement oscillations increases, and the number of frequencies increases; in terms of frictional coefficient, the amplitude of displacement oscillations increases, but the change is small compared with that of the dynamic tooth backlash, and the number of frequencies in the spectrum decreases. The results indicate that the proposed model can provide a reference for controlling the tooth roughness of high-speed gears.

Similar content being viewed by others

Data availability

The authors declare that the data supporting the findings of this study are available within the article.

References

Mughal H, Sivayogan G, Dolatabadi N, Rahmani R (2022) An efficient analytical approach to assess the root cause of nonlinear electric vehicle gear whine. Nonlinear Dyn 110:3167–3186. https://doi.org/10.1007/s11071-022-07800-0

Ho-Gil Y, Woo-** C, Beom-Soo K et al (2023) Effect of hybrid metal-composite gear on the reduction of dynamic transmission error. J Mech Sci Technol. https://doi.org/10.1007/s12206-023-0610-7

Sun M, Lu C, Liu Z et al (2020) Classifying, predicting, and reducing strategies of the mesh citations of gear whine noise: a survey. Shock Vib. https://doi.org/10.1155/2020/9834939

**ang L, Zhang Y, Gao N et al (2018) Nonlinear dynamics of multistage gear transmission system with multi-clearance. Int J Bifürcation Chaos. https://doi.org/10.1016/S0094-114X(03)00093-4

Chen J, Li W, **n G et al (2019) Nonlinear dynamic characteristics analysis and chaos control of a gear transmission system in a shearer under temperature effects. Proc Inst Mech Eng C 233:5691–5709. https://doi.org/10.1177/0954406219854112

Geng Z, **ao K, Wang J, Li J (2019) Investigation on nonlinear dynamic characteristics of a new rigid-flexible gear transmission with wear. J Vib Acoust Trans ASME 141:051008. https://doi.org/10.1115/1.4043543

Yi Y, Huang K, **ong Y, Sang M (2019) Nonlinear dynamic modelling and analysis for a spur gear system with time-varying pressure angle and gear backlash. Mech Syst Signal Process 132:18–34. https://doi.org/10.1016/j.ymssp.2019.06.013

Liu H, Zhang C, **ang CL, Wang C (2016) Tooth profile modification based on lateral-torsional-rocking coupled nonlinear dynamic model of gear system. Mech Mach Theor 105:606–619. https://doi.org/10.1016/j.mechmachtheory.2016.07.013

Li ZF, Zhu LY, Chen SQ, Chen Z, Gou X (2022) Study on safety characteristics of the spur gear pair considering time-varying backlash in the established multi-level safety domains. Nonlinear Dyn 109:1297–1324. https://doi.org/10.1007/s11071-022-07467-7

Chen J, Zhu R, Chen W et al (2023) Nonlinear dynamic modeling and analysis of helical gear system with time-varying backlash caused by mixed modification. Nonlinear Dyn 111:1193–1212. https://doi.org/10.1007/s11071-022-07872-y

Chen Q, Ma Y, Huang S, Zhai H (2014) Research on gears’ dynamic performance influenced by gear backlash based on fractal theory. Appl Surf Sci 313:325–332. https://doi.org/10.1016/j.apsusc.2014.05.210

Huang K, **ong Y, Wang T, Chen Q (2017) Research on the dynamic response of high-contact-ratio spur gears influenced by surface roughness under EHL condition. Appl Surf Sci 392:8–18. https://doi.org/10.1016/j.apsusc.2016.09.009

Chen Q, Wang Y, Tian W, Wu Y, Chen Y (2019) An improved nonlinear dynamic model of gear pair with tooth surface microscopic features. Nonlinear Dyn 96:1615–1634. https://doi.org/10.1007/s11071-019-04874-1

Li Z, Peng Z (2016) Nonlinear dynamic response of a multi-degree-of-freedom gear system dynamic model coupled with tooth surface characters: a case study on coal cutters. Nonlinear Dyn 84:271–286. https://doi.org/10.1007/s11071-015-2475-5

Hongbo Y, Wenku S, Zhiyong C, Niancheng G (2022) An improved analytical method for mesh stiffness calculation of helical gear pair considering time-varying backlash. Mech Syst Signal Process, 170. https://doi.org/10.1016/j.ymssp.2022.108882

Hinrichs N, Oestreich M (1998) On the modeling of friction oscillators. J Sound Vib 216:435–459. https://doi.org/10.1006/jsvi.1998.1736

Siyu C, **yuan T, Caiwang L, Qibo W (2011) Nonlinear dynamic characteristics of geared rotor bearing systems with dynamic backlash and friction. Mech Mach Theory 46:466–478. https://doi.org/10.1016/j.mechmachtheory.2010.11.016

Fang Y, Liang X, Zuo MJ (2018) Effects of friction and stochastic load on transient characteristics of a spur gear pair. Nonlinear Dyn 93:599–609. https://doi.org/10.1007/s11071-018-4212-3

Wang C (2020) Dynamic model of a helical gear pair considering tooth surface friction. J Vib Control 26:107754631989612. https://doi.org/10.1177/1077546319896124

Jiang H, Liu F (2022) Dynamic characteristics of helical gears incorporating the effects of coupled sliding friction. Meccanica 57:523–539). https://doi.org/10.1007/s11012-022-01477-w

Chen Q, Zhao YC, Ma YB (2014) Testing experiment of characteristic-scale coefficient about cylinder surface. J Mar Sci Technol 36:687–690. https://doi.org/10.1007/s00773-019-00684-7

Wang S, Zhu R (2022) An improved mesh stiffness model of helical gear pair considering axial mesh force and friction force influenced by surface roughness under EHL condition. Appl Math Modell 102:453–471. https://doi.org/10.1016/j.apm.2021.10.007

**n Y, Yunyun S, Shi**g W (2023) Analytical decoupling of the friction coefficient between mixed lubricated fractal surfaces. Int J Mech Sci, 255. https://doi.org/10.1016/j.ijmecsci.2023.108465

Chen ZG, Shao YM, Lim TC (2012) Non-linear dynamic simulation of gear response under the idling condition. Int J Automot Technol 13:541–552. https://doi.org/10.1007/s12239-012-0052-1

Xu H, Kahraman A (2007) Prediction of friction-related power losses of hypoid gear pairs. J Multi-body Dyn 221(3):387–400.(2007)https://doi.org/10.1243/14644193JMBD48.

Xu HE (2005) Development of a generalized mechanical efficiency prediction methodology for gear pairs. Dissertation Abstracts International, pp 104–112.

Liew HV, Lim TC (2005) Analysis of time-varying rolling element bearing characteristics. J Sound Vib 283:1163–1179. https://doi.org/10.1016/j.jsv.2004.06.022

Ouyang BCN (2019) Investigation of lubricating and dynamic performances for high-speed spur gear based on tribo-dynamic theory. Tribol Int 136:421–431. https://doi.org/10.1016/j.triboint.2019.03.009

Acknowledgements

The authors acknowledge facility resources and support provided by State Key Laboratory of High Performance Complex Manufacturing, Central South University.

Funding

This work is supported in part by the National Natural Science Foundation of China (52075552).

Author information

Authors and Affiliations

Contributions

Zhibin Zheng: Conceptualization, Methodology, Software,Data curation, Writing—Original draft preparation, Hongzhi Yan :Conceptualization,Funding acquisition, Writing—Reviewing and Editing Jiangming Wu: Visualization, Investigation. Min Ge: Software, Validation.: Yin Zhang :Writing—Reviewing and Editing

Corresponding authors

Ethics declarations

Conflict of interests

The authors declare that they have no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Zheng, Z., Yan, H., Wu, J. et al. Tribo-dynamic modelling and analysis for a high-speed helical gear system with time-varying backlash and friction under Elastohydrodynamic Lubrication condition. Meccanica (2024). https://doi.org/10.1007/s11012-024-01793-3

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s11012-024-01793-3