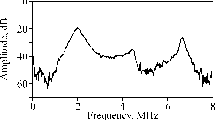

We study the surface layers of the metal of low-carbon steel after shot peening. The velocity of surface Rayleigh waves is determined by the pulse-phase method at frequencies of 3, 6, and 9 MHz with the use of contact piezoelectric transducers. The distribution of mechanical stresses over the depth is studied by tensometric measurements. The influence of different factors on variations of the velocity of surface acoustic waves is analyzed. We propose new methods for the evaluation of the thickness of plastically deformed layer of the metal after shot peening according to the frequency dependence of the velocity of these waves.

Similar content being viewed by others

References

V. Hutsaylyuk, M. Student, V. Dovhunyk, V. Posuvailo, O. Student, P. Maruschak, and I. Koval’chuck, “Effect of hydrogen on the wear resistance of steels upon contact with plasma electrolytic oxidation layers synthesized on aluminum alloys,” Metals, 9(3), 280, 1–14 (2019); https://doi.org/10.3390/met9030280.

V. Hutsaylyuk, M. Student, V. Posuvailo, O. Student, Ya. Sirak, V. Hvozdets’kyi, P. Maruschak, and H. Veselivska, “The properties of oxide-ceramic layers with Cu and Ni inclusions synthesizing by PEO method on top of the gas-spraying coatings on aluminium alloys,” Vacuum, 179, 109514, 1–11 (2020); https://doi.org/10.1016/j.vacuum.2020.109514.

T. R. Stupnyts’kyi, M. M. Student, H. V. Pokhmurs’ka, and V. M. Hvozdets’kyi, “Optimization of the chromium content of powder wires of the Fe–Cr–C and Fe–Cr–B systems according to the corrosion resistance of electric-arc coatings,” Fiz.-Khim. Mekh. Mater., 52, No. 2, 23–28 (2016); English translation: Mater. Sci., 52, No. 2, 165–172 (2016).

Y. Gong, J. Xu, and R. C. Buchanan, “Surface roughness: A review of its measurement at micro-/nano-scale,” Phys. Sci. Rev., 3, No. 1, 1–10 (2018).

B. P. Rusyn, N. P. Anufrieva, N. R. Hrabovs’ka, and V. H. Ivanyuk, “Nondestructive testing of the state of surfaces damaged by corrosion pitting,” Fiz.-Khim. Mekh. Mater., 49, No. 42, 90–96 (2013); English translation: Mater. Sci., 49, No. 4, 516–524 (2014).

L. I. Muravs’kyi, T. I. Voronyak, and A. B. Kmet’, Laser Surface Interferometry for the Needs of Technical Diagnostics [in Ukrainian], SPOLOM, Lviv (2014).

Z. T. Nazarchuk, O. E. Andreikiv, and V. R. Skalskyi, Evaluation of the Hydrogen Degradation of Ferromagnetics in Magnetic Fields [in Ukrainian], Naukova Dumka, Kyiv (2013).

Z. Nazarchuk, V. Skalskyi, and O. Serhiyenko, Acoustic Emission. Metrology and Application, Springer (2017).

J. Grum and P. Zerovnik, “Use of the Barkhausen effect in the measurement of residual stresses in steel,” Non-Destr. Test. Cond. Monit., 42, No. 12, 796–800 (2000).

P. Mora and M. Spies, “On the validity of several previously published perturbation formulas for the acoustoelastic effect on Rayleigh waves,” Ultrasonics, 91, 114–120 (2019).

J. D. Ditri and D. Hongerholt, “Stress distribution determination in isotropic materials via inversion of ultrasonic Rayleigh wave dispersion data,” Int. J. Solids Struct., 33, No. 17, 2437–2451 (1996).

A. Ruiz and P. B. Nagy, “Laser-ultrasonic surface wave dispersion measurements on surface-treated metals,” Ultrasonics, 42, 1–9 (2004).

S. Gartsev and B. Köhler, “Direct measurements of Rayleigh wave acoustoelastic constants for shot-peened superalloys,” NDT E Int., 113, 1–7 (2020).

A. A. Tarasenko, L. Jastrabìk, and N. A. Tarasenko, “Effect of roughness on the elastic surface wave propagation,” Eur. Phys. J. Appl. Phys., No. 24, 3–12 (2003).

V. V. Koshovyi, О. M. Mokryi, І. М. Hredil’, and I. M. Romanyshyn, “Investigation of the space distribution of the velocity of surface acoustic waves in plastically deformed steel by the laser method,” Fiz.-Khim. Mekh. Mater., 49, No. 4, 56–61 (2013); English translation: Mater. Sci., 49, No. 4, 478–484 (2014).

V. R. Skalskyi and О. M. Mokryi, “Evaluation of damage to ferrite-pearlite steels according to changes in the velocity of longitudinal acoustic waves,” Tekh. Diagnost. Neruin. Kontr., No. 1, 3–7 (2018).

D. Lévesque, C. S. Lim, C. Padioleau, and A. Blouin, “Measurement of texture in steel by laser-ultrasonic surface waves,” in: Proc. of the 2nd Int. Symp. “Laser-Ultrasonics—Science, Technology and Applications” (Talence, France, July 5–8, 2010), J. Phys. Conf. Ser., 278, No. 1, 012007, 1–4 (2011); DOI:https://doi.org/10.1088/1742-6596/278/1/012007.

C. Johnson and R. B. Thompson, “The spatial resolution of Rayleigh wave, acoustoelastic measurement of stress,” in: D. O. Thompson and. D. E. Chimenti (editors), Review of Progress in Quantitative Nondestruction Evaluation, Plenum Press, New York (1993), pp. 2121–2128.

M. P. Berezhnyts’ka, S. M. Kyrylenko, and A. V. Paustovskii, “Evaluation of residual stresses in bars subjected to surface hardening,” Fiz.-Khim. Mekh. Mater., 33, No. 6, 105–108 (1997); English translation: Mater. Sci., 33, No. 6, 851–861 (1997).

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated from Fizyko-Khimichna Mekhanika Materialiv, Vol. 57, No. 4, pp. 12–17, July–August, 2021.

Rights and permissions

Springer Nature or its licensor holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Skalskyi, V.R., Student, M.M., Mokryi, O.M. et al. Evaluation of the State of Subsurface Layers of the Metal Subjected to Shot Peening with the Help of Surface Acoustic Waves. Mater Sci 57, 446–451 (2022). https://doi.org/10.1007/s11003-022-00564-3

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11003-022-00564-3