Abstract

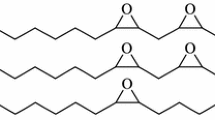

Due to the large application of polymeric materials, they have received great production demand and therefore increased the research about new synthesis technologies and sources, especially using renewable ones. In this sense, this work used the maleinized grape seed vegetable oil and a polyol with disulfide bonds to produce new renewable materials. The molar proportion between them was evaluated and thermal analysis, mid-infrared spectroscopy, gel, and bio-based contents were used to determine the dependence on properties of disulfide content (2-hydroxyethyl disulfide). Besides the thermal stability, which decreased with the disulfide increasing, the properties of maximum degradation rate, cross-linking density, Young’s modulus, and resistance to basic hydrolysis were high. All materials present elevated bio-based content and completely degrade under basic conditions after 8 h. As thermosetting, they were non-soluble even in nonpolar solvents and do not melt under heating; however, cutting and heating them at mild conditions reshaped them. Therefore, they can be considered as vitrimers.

Similar content being viewed by others

References

Chiarioni G, Van DM, Pescarmona DM. Novel elastic rubbers from CO2-based polycarbonates. Green Chem. 2023;25:7612–26. https://doi.org/10.1039/d3gc02374e.

Gbadamosi A, Patil S, Kamal MS, Adewunmi AA, Yusuff AS, Agi A, Oseh J. Application of polymers for chemical enhanced oil recovery: a review. Polym. 2022;14:1–39. https://doi.org/10.3390/polym14071433.

Dimov IB, Moser M, Malliaras GG, Mcculloch I. Semiconducting polymers for neural applications. Chem Rev. 2022;122(4):4356–96. https://doi.org/10.1021/acs.chemrev.1c00685.

Plastic Europe. Plastic the Facts 2022. https://plasticseurope.org/knowledge-hub/plastics-the-facts-2022/

Sardon H, Dove PA. Plastics recycling with a difference: a novel plastic with useful properties can easily be recycled again and again. Science. 2018;360:380–1. https://doi.org/10.1126/science.aat4997.

Pescarmona PP. Cyclic carbonates synthesised from CO2: applications, challenges and recent research trends. Curr Opin Green Sust Chem. 2021;2021(29):100457. https://doi.org/10.1016/j.cogsc.2021.100457.

Williams CK, Gregory GL. Closing the loop on recycling bioplastics: the role and rule. Nature. 2021;590:391–2.

Gaglieri C, Alarcon RT, de Moura A, Bannach G. Vegetable oils as monomeric and polymeric materials: a graphical review. Curr Res Green Sust Chem. 2022;5: 100343. https://doi.org/10.1016/j.crgsc.2022.100343.

Bei Y, Ma Y, Song F, Kou Z, Hu L, Bo C, Jia P, Zhou Y. Recent progress of biomass based self-healing polymers. J App Polym Sci. 2022;139(16):14–6. https://doi.org/10.1002/app.51977.

Nanda S, Patra BR, Patel R, Bakos J, Dalai AK. Innovations in applications and prospects of bioplastics and biopolymers: a review. Environ Chem Lett. 2022;20(1):379–95. https://doi.org/10.1007/s10311-021-01334-4.

Coppola G, Gaudio MT, Lopresto CG, Calabro V, Curcio S, Chakraborty S. Bioplastic from Renewable Biomass: a facile solution for a greener environment. Earth Syst Env. 2021;5(2):231–51. https://doi.org/10.1007/s41748-021-00208-7.

Gao Z, You Y, Chen Q, North M, **e H. Vanillin-derived α, ω-diene monomer for thermosets preparation via thiol-ene click polymerization. Green Chem. 2022. https://doi.org/10.1039/d2gc02901d.

Guo Y, Guo G, Liu P, You Y, Yuan J, Hu G, Dai L, North M, **e H, Zheng Q. The synthesis of multifunctional cellulose graft alternating copolymers of 3,4-dihydrocoumarin and epoxides in DBU/DMSO/CO2 solvent system. Inter J Biol Macrom. 2023;252: 126584. https://doi.org/10.1016/j.ijbiomac.2023.126584.

Sheldon RA, Norton M. Green chemistry and the plastic pollution challenge: towards a circular economy. Green Chem. 2020;22(19):6310–22. https://doi.org/10.1039/d0gc02630a.

Gaglieri C, Alarcon R, de Moura A, Magri R, da Silva-Filho L, Bannach G. Green and efficient modification of grape seed oil to synthesize renewable monomers. J Braz Chem Soc. 2021;32(11):2120–21331. https://doi.org/10.21577/0103-5053.20210104.

Alarcon RT, Lamb KJ, Cavalheiro ÉTG, North M, Bannach G. A screening process for carbonation of vegetable oils using an aluminum(salen) complex with a further application as weldable polymers. J App Polym Sci. 2023;140(24):1–14. https://doi.org/10.1002/app.53962.

Alarcon RT, Gaglieri C, Lamb KJ, Cavalheiro ÉTG, North M, Bannach G. A new acrylated monomer from macaw vegetable oil that polymerizes without external photoinitiators. J Polym Res. 2021;28:11. https://doi.org/10.1007/s10965-021-02787-5.

Melendez-Zamudio M, Donahue-Boyle E, Chen Y, Brook MA. Acrylated soybean oil: a key intermediate for more sustainable elastomeric materials from silicones. Green Chem. 2022;25(1):280–7. https://doi.org/10.1039/d2gc04073e.

International Organisation of Vine and Wine. Country Statistics, available at https://www.oiv.int/what-we-do/country-report?oiv, assessed 08 out 2023.

Empresa Brasileira de Pesquisa Agropecuária (Embrapa); Vitivinicultura Brasileira: Panorama 2021. available at https://ainfo.cnptia.embrapa.br/digital/bitstream/doc/1149674/1/Com-Tec-226.pdf, accessed in 08 October 2023.

Alarcon RT, Lamb KJ, Bannach G, North M. Opportunities for the use of Brazilian biomass to produce renewable chemicals and materials. Chemsuschem. 2021;14(1):169–88. https://doi.org/10.1002/cssc.202001726.

Hogervorst JC, Miljiic U, Puskas V. In Handbook of Grape Processing By-Products. London: Academic Press; 2017.

Alarcon RT, Gaglieri C, de Souza OA, Rinaldo D, Bannach G. Microwave-assisted syntheses of vegetable oil-based monomer: a cleaner, faster, and more energy efficient route. J Polym Env. 2020;28(4):1265–78. https://doi.org/10.1007/s10924-020-01680-4.

Shcherban ND, Diyuk EA, Sydorchuk VV. Synthesis and catalytic activity of vanadium phosphorous oxides systems supported on silicon carbide for the selective oxidation of n-butane to maleic anhydride. Reac Kin Mech Cat. 2019;126(2):975–85. https://doi.org/10.1007/s11144-018-01530-4.

Müller M, Kutscherauer M, Böcklein S, Wehinger GD, Turek T, Mestl G. Modeling the selective oxidation of n-butane to maleic anhydride: from active site to industrial reactor. Cat Today. 2022;387:82–106. https://doi.org/10.1016/j.cattod.2021.04.009.

Cucciniello R, Cspi D, Riccardi M, Neri E, Passarini F, Pulselli FM. Maleic anhydride from bio-based 1-butanol and furfural: a life cycle assessment at the pilot scale. Green Chem. 2023;15(25):5922–35. https://doi.org/10.1039/D2GC03707F.

Alarcon RT, Gaglieri C, Santos GC, Moralles AC, Morgon NH, Souza AR, Bannach G. AIE effect by oxygen clustering in vegetable oil-based polymers. ChemistrySelect. 2021;6(31):7838–44. https://doi.org/10.1002/slct.202100889.

Tarik E, Kusefoglu SH, Wool R. Polymerization of maleic anhydride–modified plant oils with polyols. J Appl Polym Sci. 2003;90(1):197–202.

Carbonell-Verdu A, Garcia-Garcia D, Domicini F, Torre L, Sanchez-Nacher L, Balart R. PLA films with improved flexibility properties by using maleinized cottonseed oil. Eur Polymer J. 2017;91:248–59.

Nagy B, Torok F, Tomasek S, Miskolczi N. Vegetable oil based additives to enhance the properties of PLA/Starch composites: the effect of reaction parameters. Ind Crops Prod. 2023;191: 116025.

Wang M, Gao H, Wang Z, Mao Y, Yang J, Wu B, ** L, Zhang C, **a Y, Zhang K. Rapid self-healed vitrimers via tailored hydroxyl esters and disulfide bonds. Polym. 2021;248(6):124801. https://doi.org/10.1016/j.polymer.2022.124801.

Li B, Zhu G, Hao Y, Ren T. Shape reconfiguration and functional self-healing of thermadapt shape memory epoxy vitrimers by exchange reaction of disulfide bonds. Smart Mat Struc. 2022;31(9): 095047. https://doi.org/10.1088/1361-665X/ac8777.

Roig A, Agizza M, Serra À, de La Flor S. Disulfide vitrimeric materials based on cystamine and diepoxy eugenol as bio-based monomers. Eur Polym J. 2023;194: 112185. https://doi.org/10.1016/j.eurpolymj.2023.112185.

Kumar EK, Patel SS, Kumar V, Panda SK, Mahmoud SR, Balubaid M. State of art review on applications and mechanism of self-healing materials and structure. Arch Comput Methods Eng. 2023;30:1041. https://doi.org/10.1007/s11831-022-09827-3.

Kim MS, Chang H, Zheng L, Yan Q, Pleger BF, Klier J, Nelson K, Majumder ELW, Huber GW. A review of biodegradable plastics: chemistry, applications, properties, and future research needs. Chem Rev. 2023;123:9915. https://doi.org/10.1021/acs.chemrev.2c00876.

Pena-Francesch A, Jung H, Demirel MC, Sitti M. Biosynthetic self-healing materials for soft machines. Nat Mater. 2020;19(11):1230–5. https://doi.org/10.1038/s41563-020-0736-2.

Roels E, Terryn S, Lida F, Bosman AW, Norvez S, Clemens F, Assche GV, Vanderborght B, Brancart J. Processing of self-healing polymers for soft robotics. Adv Mater. 2022;34:2104798. https://doi.org/10.1002/adma.20210479.

Kalogeropoulou M, Díaz-Payno PJ, Mirzaali MJ, van Osch GJVM, Fratila-Apachitei L, Zadpoor AA. 4D printed shape-shifting biomaterials for tissue engineering and regenerative medicine applications. Biofabrication. 2024;16: 022002. https://doi.org/10.1088/1758-5090/ad1e6f.

Dong J, Liu B, Ding H, Shi J, Liu N, Dai B, Kim I. Bio-based healable non-isocyanate polyurethanes driven by the cooperation of disulfide and hydrogen bonds. Polym Chem. 2020;11(47):7524–32. https://doi.org/10.1039/d0py01249a.

Gaglieri C, Alarcon RT, Magri R, North M, Bannach G. Development of renewable thermosetting polymers based on grape seed oil derivatives. J App Polym Sci. 2022;139(41):1–13. https://doi.org/10.1002/app.52990.

Candy L, Vaca-Garcia C, Borredon E. Synthesis and characterization of oleic succinic anhydrides: structure-property relations. JAOCS. 2005;82(4):271–7. https://doi.org/10.1007/s11746-005-1066-5.

Magri R, Gaglieri C, Alarcon RT, dos Santos GI, Bannach G. From patauá oil to sustainable polymers: investigation of epoxy/anhydride crosslink in different proportions. J Polym Env. 2023. https://doi.org/10.1007/s10924-023-03061-z.

Noè C, Iannucci L, Malburet S, Graillot A, Sangermano M, Grassini S. New UV-curable anticorrosion coatings from vegetable oils. Macrom Mat Eng. 2021;306(6):1–11. https://doi.org/10.1002/mame.202100029.

Hernández E, Mosiewicki MA, Marcovich NE. Bio-based polymers obtained from modified fatty acids and soybean oil with tailorable physical and mechanical performance. Eur J Lip Sci Technol. 2020;122(10):1–12. https://doi.org/10.1002/ejlt.202000182.

Pawlak F, Aldas M, López-Martínez J, Samper MD. Effect of different compatibilizers on injection-molded green fiber-reinforced polymers based on poly(lactic acid)-maleinized linseed oil system and sheep wool. Polym. 2019;11(9):1514. https://doi.org/10.3390/polym11091514.

Funding

Funding was involved in São Paulo Research Foundation—FAPESP (Grants 2021/02152–9, 2021/14879–0, and 2022/03489–0) and National Council for Scientific and Technological Development-CNPq (Grants 303247/2021–5 and 150233/2022–1) for financial support.

Author information

Authors and Affiliations

Contributions

All authors contributed to the study’s conception and design. Material preparation, data collection, and analysis were performed by Caroline Gaglieri, Rafael T. Alarcon, and Gabriel I. dos Santos. The first draft of the manuscript was written by Caroline Gaglieri and Rafael T. Alarcon, and all authors commented on previous versions of the manuscript. All authors read and approved the final manuscript.

Corresponding author

Ethics declarations

Conflicts of interest

There are no conflicts to declare.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Gaglieri, C., Alarcon, R.T., dos Santos, G.I. et al. Renewable disulfide-based polyesters: highly cross-linked, vitrimers, and biodegradable materials. J Therm Anal Calorim (2024). https://doi.org/10.1007/s10973-024-13102-x

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s10973-024-13102-x