Abstract

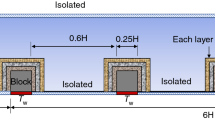

Flat plate solar collectors are extensively used in buildings, however due to excessive heat losses, these collectors are not efficient. Metal foams can enhance the thermal efficiency in expense of higher pum** power. A numerical simulation is carried out to investigate the influence of geometrical characteristics of porous medium on the pressure drop and heat transfer. An innovative design with gradually increasing or decreasing height is proposed. Porous block consists of three smaller blocks, two rectangular blocks at the inlet and outlet connected with a trapezoidal block. Non-dimensional height and length of the rectangular blocks vary between 0.2–0.6 and 0.1–0.9 respectively, and the optimum geometry of the porous block is proposed. Central composite design is conducted to find an optimum geometrical design and 25 design points have been investigated. The main target of this optimization is the simultaneous increment of Nusselt and decrement of pressure drop. Results demonstrate that porous block with non-dimensional inlet and outlet height of 0.9 and 0.5 and inlet and outlet length of 0.4 and 0.4 respectively, result in the highest Nu (= 15.2). Comparing the optimal results with those of a conventional rectangular porous block with constant height of 0.9 represents that in the optimum design Nu is only 7.23% less than that of the conventional design, while, pressure drop is improved up to 38.46% in the proposed geometrical design. Additionally, response surface methodology has been carried out and results have been reported in response surface plots.

Similar content being viewed by others

Abbreviations

- \(\mu\) :

-

Dynamic viscosity (Pa. s)

- C d :

-

Non-linear Forchheimer coefficient

- \(\rho\) :

-

Density (kg m−3)

- C p :

-

Specific heat (J kg−1 K−1)

- D h :

-

Hydraulic diameter (m)

- Eff:

-

Effective

- d p :

-

Pore diameter of porous media (m)

- F :

-

Fluid

- G :

-

Gravitational acceleration (m s−2)

- I :

-

Inner

- H :

-

Channel height (m)

- M :

-

Middle

- H :

-

Heat transfer coefficient (w/m2)

- O :

-

Outer

- K :

-

Thermal conductivity (W m−1 K−1)

- L :

-

Channel length (m)

- ASHRAE:

-

The American society of heating, refrigerating and air-conditioning engineers

- Nu:

-

Nusselt number

- CCD:

-

Central composite design

- P :

-

Pressure (kPa)

- DOE:

-

Design of experiments

- q w :

-

Heat flux (w)

- FPSC:

-

Flat plate solar collector

- T :

-

Temperature (K)

- MWCNT:

-

Multi-walled carbon nanotubes

- V :

-

Velocity vector (m s−1)

- LTE:

-

Local thermal equilibrium

- T :

-

Temperature (K)

- LTNE:

-

Local thermal non-equilibrium

- PV:

-

Photovoltaic

- \(\alpha\) :

-

Inclination angle (°)

- RSM:

-

Response surface methodology

- \(\varepsilon\) :

-

Porosity

- SIMPLE:

-

Semi-implicit method for pressure linked equations

- K :

-

Permeability (m2)

References

Ahmadi A, Ganji DD, Jafarkazemi F. Analysis of utilizing Graphene nanoplatelets to enhance thermal performance of flat plate solar collectors. Energy Convers Manag. 2016;126:1–11.

Hussein OA, Habib K, Muhsan AS, Saidur R, Alawi OA, Ibrahim TK. Thermal performance enhancement of a flat plate solar collector using hybrid nanofluid. Sol Energy. 2020;204:208–22.

Fuqiang W, Jianyu T, Lanxin M, Chengchao W. Effects of glass cover on heat flux distribution for tube receiver with parabolic trough collector system. Energy Convers Manag. 2015;90:47–52.

Xu G, Zhao S, Zhang X, Zhou X. Experimental thermal evaluation of a novel solar collector using magnetic nano-particles. Energy Convers Manag. 2016;130:252–9.

Deng Y, Zhao Y, Wang W, Quan Z, Wang L, Yu D. Experimental investigation of performance for the novel flat plate solar collector with micro-channel heat pipe array (MHPA-FPC). Appl Therm Eng. 2013;54(2):440–9.

Saedodin S, Zamzamian S, Nimvari ME, Wongwises S, Jouybari HJ. Performance evaluation of a flat-plate solar collector filled with porous metal foam: experimental and numerical analysis. Energy Convers Manag. 2017;153:278–87.

Jouybari HJ, Saedodin S, Zamzamian A, Nimvari ME. Experimental investigation of thermal performance and entropy generation of a flat-plate solar collector filled with porous media. Appl Therm Eng. 2017;127:1506–17.

Biçer A, Devecioğlu AG, Oruç V, Tuncer Z. Experimental investigation of a solar air heater with copper wool on the absorber plate. Int J Green Energy. 2020;17(15):979–89.

Languri EM, Taherian H, Hooman K, Reisel J. Enhanced double-pass solar air heater with and without porous medium. Int J Green Energy. 2011;8(6):643–54.

Firoozzadeh M, Shafiee M. Thermodynamic analysis on using titanium oxide/oil nanofluid integrated with porous medium in an evacuated tube solar water heater. J Therm Anal Calorim. 2023;148:1–14.

Ahmadinejad M, Soleimani A, Gerami A. Performance enhancement of a photovoltaic thermal (PVT) system with sinusoidal fins: A quasi-transient energy-exergy analysis. Int J Green Energy. 2023;20:978–96.

Nedjem K, Laouer A, Teggar M, Mezaache EH, Arıcı M, Ismail KA. Performance enhancement of triplex tube latent heat storage using fins, metal foam and nanoparticles. Int Commun Heat Mass Transfer. 2022;139: 106437.

Fattoum R, Hidouri A, Attia MEH, Arıcı M, Abbassi MA. Performance optimization of solar air heater using inclined ribs. J Therm Anal Calorim. 2023;148:1–13.

Ahmadi M, Ahmadlouydarab M, Maysami M. Effects of heat–light source on the thermal efficiency of flat plate solar collector when nanofluid is used as service fluid. J Therm Anal Calorim. 2023;148:7477–500.

Aghili Yegane SP, Kasaeian A. Thermal performance assessment of a flat-plate solar collector considering porous media, hybrid nanofluid and magnetic field effects. J Therm Anal Calorim. 2020;141:1969–80.

Michael Joseph Stalin P, Arjunan T, Matheswaran M, Dolli H, Sadanandam N. Energy, economic and environmental investigation of a flat plate solar collector with CeO2/water nanofluid. J Therm Anal Calorim. 2020;139:3219–33.

Selimefendigil F, Öztop HF. Comparative study on different cooling techniques for photovoltaic thermal management: hollow fins, wavy channel and insertion of porous object with hybrid nanofluids. Appl Therm Eng. 2023;228: 120458.

Jouybari HJ, Saedodin S, Zamzamian A, Nimvari ME, Wongwises S. Effects of porous material and nanoparticles on the thermal performance of a flat plate solar collector: an experimental study. Renew Energy. 2017;114:1407–18.

Li Y, Fernández-Seara J, Du K, Pardiñas ÁÁ, Latas LL, Jiang W. Experimental investigation on heat transfer and pressure drop of ZnO/ethylene glycol-water nanofluids in transition flow. Appl Therm Eng. 2016;93:537–48.

Shojaeizadeh E, Veysi F, Yousefi T, Davodi F. An experimental investigation on the efficiency of a Flat-plate solar collector with binary working fluid: a case study of propylene glycol (PG)–water. Exp Therm Fluid Sci. 2014;53:218–26.

Yousefi T, Veysi F, Shojaeizadeh E, Zinadini S. An experimental investigation on the effect of Al2O3–H2O nanofluid on the efficiency of flat-plate solar collectors. Renew Energy. 2012;39(1):293–8.

Yousefi T, Shojaeizadeh E, Veysi F, Zinadini S. An experimental investigation on the effect of pH variation of MWCNT–H2O nanofluid on the efficiency of a flat-plate solar collector. Sol Energy. 2012;86(2):771–9.

Tong Y, Chi X, Kang W, Cho H. Comparative investigation of efficiency sensitivity in a flat plate solar collector according to nanofluids. Appl Therm Eng. 2020;174: 115346.

Mahian O, Kianifar A, Sahin AZ, Wongwises S. Performance analysis of a minichannel-based solar collector using different nanofluids. Energy Convers Manag. 2014;88:129–38.

Tong Y, Lee H, Kang W, Cho H. Energy and exergy comparison of a flat-plate solar collector using water, Al2O3 nanofluid, and CuO nanofluid. Appl Therm Eng. 2019;159: 113959.

Nield DA, Bejan A, et al. Convection in porous media, vol. 3. Springer; 2006.

Vadász P. Emerging topics in heat and mass transfer in porous media: from bioengineering and microelectronics to nanotechnology. Springer; 2008.

Wang F, Tan J, Wang Z. Heat transfer analysis of porous media receiver with different transport and thermophysical models using mixture as feeding gas. Energy Convers Manag. 2014;83:159–66.

Sorour M. A new type of solar water heater. Int J Energy Res. 1985;9(1):27–32.

Sopian K, Daud WRW, Othman MY, Yatim B, et al. Thermal performance of the double-pass solar collector with and without porous media. Renew Energy. 1999;18(4):557–64.

Shu G, **ao T, Guo J, Wei P, Yang X, He YL. Effect of charging/discharging temperatures upon melting and solidification of PCM-metal foam composite in a heat storage tube. Int J Heat Mass Transf. 2023;201: 123555.

Chen Z, Gu M, Peng D. Heat transfer performance analysis of a solar flat-plate collector with an integrated metal foam porous structure filled with paraffin. Appl Therm Eng. 2010;30(14–15):1967–73.

Hirasawa S, Tsubota R, Kawanami T, Shirai K. Reduction of heat loss from solar thermal collector by diminishing natural convection with high-porosity porous medium. Sol Energy. 2013;97:305–13.

Omri M, Selimefendigil F, Smaoui HT, Kolsi L. Cooling system design for photovoltaic thermal management by using multiple porous deflectors and nanofluid. Case Stud Therm Eng. 2022;39: 102405.

Xu H, Gong L, Huang S, Xu M. Non-equilibrium heat transfer in metal-foam solar collector with no-slip boundary condition. Int J Heat Mass Transf. 2014;76:357–65.

Rashidi S, Bovand M, Esfahani J. Heat transfer enhancement and pressure drop penalty in porous solar heat exchangers: a sensitivity analysis. Energy Convers Manag. 2015;103:726–38.

Anirudh K, Dhinakaran S. Numerical study on performance improvement of a flat-plate solar collector filled with porous foam. Renew Energy. 2020;147:1704–17.

Al-Nimr M, Alkam M. A modified tubeless solar collector partially filled with porous substrate. Renew Energy. 1998;13(2):165–73.

Alkam MK, Al-Nimr MA. Solar collectors with tubes partially filled with porous substrates. J Solar Energy Eng. 1999;121:20–4.

Huang PC, Chen CC, Hwang HY. Thermal enhancement in a flat-plate solar water collector by flow pulsation and metal-foam blocks. Int J Heat Mass Transf. 2013;61:696–720.

Anirudh K, Dhinakaran S. Performance improvement of a flat-plate solar collector by inserting intermittent porous blocks. Renew Energy. 2020;145:428–41.

Anirudh K, Dhinakaran S. Numerical analysis of the performance improvement of a flat-plate solar collector using conjugated porous blocks. Renew Energy. 2021;172:382–91.

Sankar SSK, et al. Recent advancements in flat plate solar collector using phase change materials and nanofluid: a review. Environ Sci Pollut Res. 2023;30(38):88366–86.

Teamah H, Teamah M. Integration of phase change material in flat plate solar water collector: a state of the art, opportunities, and challenges. J Energy Storage. 2022;54:105357.

Sajedi A, Farahani SD, Ad Alizadeh A. Numerical investigation and group method of data handling-based prediction on new flat plate solar collector integrated with nanoparticles enhanced phase change materials and tube rotation mechanism. J Energy Storage. 2023;67:107542.

Palacio M, Rincón A, Carmona M. Experimental comparative analysis of a flat plate solar collector with and without PCM. Sol Energy. 2020;206:708–21.

Sharma HK, Kumar S, Kumar S, Verma SK. Performance investigation of flat plate solar collector with nanoparticle enhanced integrated thermal energy storage system. J Energy Storage. 2022;55: 105681.

Algarni S. Evaluation and optimization of the performance and efficiency of a hybrid flat plate solar collector integrated with phase change material and heat sink. Case Stud Therm Eng. 2023;45: 102892.

NematpourKeshteli A, Iasiello M, Langella G, Bianco N. Increasing melting and solidification performances of a phase change material-based flat plate solar collector equipped with metal foams, nanoparticles, and wavy wall-Y-shaped surface. Energy Convers Manag. 2023;291: 117268.

Selimefendigil F, Öztop HF. Optimization assisted CFD for using double porous cylinders on the performance improvement of TEG mounted 3D channels. Sustain Energy Technol Assess. 2022;52: 102303.

Ren F, Du J, Yang X, Huang X. Optimization on a novel irregular snowflake fin for thermal energy storage using response surface method. Int J Heat Mass Transf. 2023;200: 123521.

Afzal A, et al. Optimizing the thermal performance of solar energy devices using meta-heuristic algorithms: a critical review. Renew Sustain Energy Rev. 2023;173: 112903. https://doi.org/10.1016/j.rser.2022.112903.

Liu Z, Yang X, Ali HM, Liu R, Yan J. Multi-objective optimizations and multi-criteria assessments for a nanofluid-aided geothermal PV hybrid system. Energy Rep. 2023;9:96–113.

Huang X, Li F, Li Y, Meng X, Yang X, Sundén B. Optimization of melting performance of a heat storage tank under rotation conditions: Based on taguchi design and response surface method. Energy. 2023;271: 127100.

Huang X, Li F, Lu L, Li Z, Yang X, Yan J. Depth optimization of solidification properties of a latent heat energy storage unit under constant rotation mechanism. Energy Build. 2023;290: 113099.

Siavashi M, Bahrami HRT, Aminian E. Optimization of heat transfer enhancement and pum** power of a heat exchanger tube using nanofluid with gradient and multi-layered porous foams. Appl Therm Eng. 2018;138:465–74.

Siavashi M, Bahrami HRT, Saffari H. Numerical investigation of porous rib arrangement on heat transfer and entropy generation of nanofluid flow in an annulus using a two-phase mixture model. Numer Heat Transf, Part A: Appl. 2017;71(12):1251–73.

Calmidi VV, Mahajan RL. Forced convection in high porosity metal foams. J Heat Transf. 2000;122(3):557–65.

Bovand M, Rashidi S, Esfahani J. Heat transfer enhancement and pressure drop penalty in porous solar heaters: Numerical simulations. Sol Energy. 2016;123:145–59.

Thomareis AS, Dimitreli G. Techniques used for processed cheese characterization, in processed cheese science and technology. Elsevier; 2022. p. 295–349.

Sahoo P, Barman TK. ANN modeling of fractal dimension in machining, in mechatronics and manufacturing engineering. Elsevier; 2012. p. 159–226.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Variji, N., Hosseini Imeni, S.Z. & Siavashi, M. Multi-objective optimization of porous foam structure to enhance energy performance of flat plate solar collectors. J Therm Anal Calorim 149, 3543–3559 (2024). https://doi.org/10.1007/s10973-024-12937-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10973-024-12937-8