Abstract

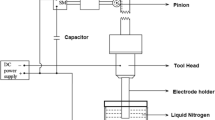

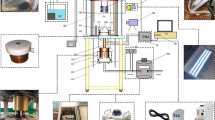

Open microchannels and micro/nanoporous coatings by nanofluid boiling have been used separately by earlier researchers to improve heat transfer during pool boiling. The combined impact of these factors is examined in this work by novel ZnO-coated Cu (Cu@ZnO) hybrid nanofluid boiling on the apex of microchannels’ fins, resulting in development of micro/nanoporous coatings on the apex of microchannels’ fins. The Cu@ZnO hybrid nanoparticles were prepared by optimal spark discharging in liquid nitrogen. The next phase involves dispersing the developed nanoparticles in DI water as the base fluid to achieve stable nanofluids. This article reports on the impact of microchannel geometry on the efficiency of heat transmission for water and hybrid nanofluid boiling on copper chips. A higher concentration of nanofluid with microchannel configuration enhanced the CHF and HTC throughout the pool boiling experiment. The highest increases in HTC and CHF were reported to be 287.57% and 123.60%, respectively, for 0.1% hybrid nanofluid on 300-µm microchannel. The mechanisms of bubble formation and heat transport are changed when nucleation occurs mostly on the fin tops. The present study’s theory is founded on the improved rewetting routes offered by microchannels and the extra nucleation spots offered by porous layers, both of which operate in concert to improve boiling behaviour. A microconvective process wherein highly localized liquid circulating currents are created in the microchannels by bubbles emerging from the tops of the fins. Additionally, a conceptual framework based on liquid microcirculation is suggested.

Similar content being viewed by others

Data availability

Data and materials will be provided on request.

References

Alkharabsheh S, Fernandes J, Gebrehiwot B, Agonafer D, Ghose K, Ortega A, Joshi Y, Sammakia B. A brief overview of recent developments in thermal management in data centers. J Electron Packag. 2015;137:040801.

Zhu JF, Li XY, Wang SL, Yang YR, Wang XD. Performance comparison of wavy microchannel heat sinks with wavy bottom rib and side rib designs. Int J Therm Sci. 2019;146:106068.

Kheirabadi AC, Groulx D. Cooling of server electronics: a design review of existing technology. Appl Therm Eng. 2016;105:622–38.

Cao Z. Pool boiling on structured surfaces: heat transfer and critical heat flux experiments and mechanistic modelling. Doctor Dissertation, Lund University: Lund. 2019.

Kuncoro IW, Pambudi NA, Biddinika MK, Widiastuti I, Hijriawan M, Wibowo KM. Immersion cooling as the next technology for data center cooling: a review. J Phys Conf Ser. 2019;1402:044057.

Gupta SK, Misra RD. Experimental pool boiling heat transfer analysis with copper-alumina micro/nanostructured surfaces developed by a novel electrochemical deposition technique. Int J Thermophys. 2023;44:112.

Birbarah P, Gebrael T, Foulkes T, Stillwell A, Moore A, Pilawa-Podgurski R, Miljkovic N. Water immersion cooling of high power density electronics. Int J Heat Mass Transf. 2020;147:118918.

Hsu YT, Li JX, Lu MC. Enhanced immersion cooling using two-tier micro- and nano-structures. Appl Therm Eng. 2018;131:864–73.

Wang Y, Pambudi NA, Bugis H, Kuncoro IW, Setiawan ND, Hijriawan M, Rudiyanto B, Basori B. Preliminary experimental of GPU immersion-cooling. E3S Web Conf. 2019;93:03003.

Ahangar Zonouzi S, Aminfar H, Mohammadpourfard M. A review on effects of magnetic fields and electric fields on boiling heat transfer and CHF. Appl Therm Eng. 2019;151:11–25.

Bourdon B, Rioboo R, Marengo M, Gosselin E, Coninck JD. Influence of the wettability on the boiling onset. Langmuir. 2012;28:1618–24.

Ze H, Wu F, Chen S, Gao X. Superhydrophilic composite structure of copper microcavities and nanocones for enhancing boiling heat transfer. Adv Mater Interfaces. 2020;7:2000482.

Xu P, Li Q, Xuan Y. Enhanced boiling heat transfer on composite porous surface. Int J Heat Mass Transf. 2015;80:107–14.

Wu F, Ze H, Chen S, Gao X. Highly-efficiency boiling heat transfer interface composed of electroplated copper nanocone cores and low-thermal-conductivity nickel nanocone covering. ACS Appl Mater Interfaces. 2020;12:39902–9.

Li J, Fu W, Zhang B, Zhu G, Miljkovic N. Ultrascalable three-tier hierarchical nanoengineered surfaces for optimized boiling. ACS Nano. 2019;13:14080–93.

Wu Z, Cao Z, Sunden B. Saturated pool boiling heat transfer ́ of acetone and HFE-7200 on modified surfaces by electrophoretic and electrochemical deposition. Appl Energy. 2019;249:286–99.

Cao Z, Wu Z, Sunden B. Heat transfer prediction and ́ critical heat flux mechanism for pool boiling of NOVEC-649 on microporous copper surfaces. Int J Heat Mass Transf. 2019;141:818–34.

El-Genk MS, Ali AF. Enhanced nucleate boiling on copper micro-porous surfaces. Int J Multiphase Flow. 2010;36:780–92.

Furberg R, Palm B. Boiling heat transfer on a dendritic and micro-porous surface in R134a and FC-72. Appl Therm Eng. 2011;31:3595–603.

White SB, Shih AJ, Pipe KP. Boiling surface enhancement by electrophoretic deposition of particles from a nanofluid. Int J Heat Mass Transf. 2011;54:4370–5.

Song G, Davies PA, Wen J, Xu G, Quan Y. Nucleate pool boiling heat transfer of SES36 fluid on nanoporous surfaces obtained by electrophoretic deposition of Al2O3. Appl Therm Eng. 2018;141:143–52.

Cao Z, Wu Z, Pham AD, Yang Y, Abbood S, Falkman P, Ruzgas T, Alber C, Sunde NB. Pool boiling of HFE-7200 on ́ nanoparticle-coating surfaces: experiments and heat transfer analysis. Int J Heat Mass Transf. 2019;133:548–60.

Cao Z, Wu Z, Pham AD, Sunden B. Electrophoretic ́ deposition surfaces to enhance HFE-7200 pool boiling heat transfer and critical heat flux. Int J Therm Sci. 2019;146:106107.

Zhao H, Dash S, Dhillon NS, Kim S, Lettiere B, Varanasi KK, Hart AJ. Microstructured ceramic-coated carbon nanotube surfaces for high heat flux pool boiling. ACS Appl Nano Mater. 2019;2:5538–45.

Jaikumar A, Gupta A, Kandlikar SG, Yang CY, Su CY. Scale effects of graphene and graphene oxide coatings on pool boiling enhancement mechanisms. Int J Heat Mass Transf. 2017;109:357–66.

Pratik KC, Nammari A, Ashton TS, Moore AL. Saturated pool boiling heat transfer from vertically oriented silicon surfaces modified with foam-like hexagonal boron nitride nanomaterials. Int J Heat Mass Transf. 2016;95:964–71.

Zou A, Poudel S, Raut PS, Maroo CS. Pool boiling coupled with nanoscale evaporation using buried nanochannels. Langmuir. 2019;35:12689–93.

Prakash Chakrapani Gunarasan J, Ravindran P. Significance of chemical engineering in surface wettability tuning and its boiling hydrodynamics: a boiling heat transfer study. Ind Eng Chem Res. 2020;59:4210–8.

Ridwan S, McCarthy M. Nanostructure-supported evaporation underneath a growing bubble. ACS Appl Mater Interfaces. 2019;11:12441–51.

Liu M, Lu K, Li X, Liu H, **g D. Light-induced enhancement of critical heat flux on TiO2 coatings with specific surface topology. Appl Therm Eng. 2020;174:115333.

Su CY, Yang CY, Jhang BW, Hsieh YL, Sin YY, Huang CC. Pool boiling heat transfer enhanced by fluorinated graphene as atomic layered modifiers. ACS Appl Mater Interfaces. 2020;12:10233–9.

Moze M, Senegacnik M, Gregorcic P, Hocevar M, Zupancic M, Golobic I. Laser-engineered microcavity surfaces with a nanoscale superhydrophobic coating for extreme boiling performance. ACS Appl Mater Interfaces. 2020;12:24419–31.

Kong D, Kang M, Kim KY, Jang J, Cho J, In JB, Lee H. Hierarchically structured laser-induced graphene for enhanced boiling on flexible substrates. ACS Appl Mater Interfaces. 2020;12:37784–92.

Liu B, Liu J, Zhou J, Yuan B, Zhang Y, Wei J, Wang W. Experimental study of subcooled boiling pool heat transfer and its “hook back” phenomenon on micro/nanostructured surfaces. Int Commun Heat Mass Transf. 2019;100:73–82.

Liu B, Cao Z, Zhang Y, Wu Z, Pham A, Wang W, Yan Z, Wei J, Sunden B. Pool boiling heat transfer of N-pentane on micro/nanostructured surfaces. Int J Therm Sci. 2018;130:386–94.

Chen R, Lu MC, Srinivasan V, Wang Z, Cho HH, Majumdar A. Nanowires for enhanced boiling heat transfer. Nano Lett. 2009;9:548–53.

Shim DI, Choi G, Lee N, Kim T, Kim BS, Cho HH. Enhancement of pool boiling heat transfer using aligned silicon nanowire arrays. ACS Appl Mater Interfaces. 2017;9:17595–602.

Shin S, Choi G, Rallabandi B, Lee D, Shim DI, Kim BS, Kim KM, Cho HH. Enhanced boiling heat transfer using self-actuated nanobimorphs. Nano Lett. 2018;18:6392–6.

Kim DE, Park SC, Yu DI, Kim MH, Ahn HS. Enhanced critical heat flux by capillary driven liquid flow on the welldesigned surface. Appl Phys Lett. 2015;107:023903.

Rahman MM, Ridwan S, Fehlinger D, McCarthy M. Wicking enhanced critical heat flux for highly wetting fluids on structured surfaces. Langmuir. 2020;36:9643–8.

Liu B, Yu L, Zhang Y, Marco PD, Wei J. Enhanced nucleate pool boiling by coupling the pinning act and cluster bubble nucleation of micro-nano composited surfaces. Int J Heat Mass Transfer. 2020;157:119979.

Kim DE, Yu DI, Park SC, Kwak HJ, Ahn HS. Critical heat flux triggering mechanism on micro-structured surfaces: coalesced bubble departure frequency and liquid furnishing capability. Int J Heat Mass Transf. 2015;91:1237–47.

Zou A, Singh PD, Maroo CS. Early evaporation of microlayer for boiling heat transfer enhancement. Langmuir. 2016;32:10808–14.

Chu KH, Enright R, Wang EN. Structured surfaces for enhanced pool boiling heat transfer. Appl Phys Lett. 2012;100:241603.

Zhou J, Liu B, Qi B, Wei J, Mao H. Experimental investigations of bubble behaviors and heat transfer performance on micro/nanostructure surfaces. Int J Therm Sci. 2019;135:133–47.

Cooke D, Kandlikar SG. Effect of open microchannel geometry on pool boiling enhancement. Int J Heat Mass Transf. 2012;55(4):1004–13.

You SM, Kim JH, Kim KH. Effect of nanoparticles on critical heat flux of water in pool boiling heat transfer. Appl Phys Lett. 2003;83(16):3374–6.

Forrest E, Williamson E, Buongiorno J, Hu LW, Rubner M, Cohen R. Augmentation of nucleate boiling heat transfer and critical heat flux using nanoparticle thin-film coatings. Int J Heat Mass Transf. 2010;53:58–67.

Kalani A, Kandlikar SG. Enhanced pool boiling with ethanol at subatmospheric pressures for electronics cooling. J Heat Transf. 2013;135:11.

Rainey KN, You SM, Lee S. Effect of pressure, subcooling, and dissolved gas on pool boiling heat transfer from microporous, square pin-finned surfaces in FC-72. Int J Heat Mass Transf. 2003;46:23–35.

Patil CM, Santhanam KSV, Kandlikar SG. Development of a two-step electrodeposition process for enhancing pool boiling. Int J Heat Mass Transf. 2014;79:989–1001.

Patil CM, Kandlikar SG. Pool boiling enhancement through microporous coatings selectively electrodeposited on fin tops of open microchannels. Int J Heat Mass Transf. 2014;79:816–28.

Kabbara H, Ghanbaja J, Noël C, Belmonte T. Synthesis of Cu@ZnO core–shell nanoparticles by spark discharges in liquid nitrogen. Nano-Struct Nano-Objects. 2017;10:22–9.

Barewar SD, Chougule SS, Jadhav J, Biswas S. Synthesis and thermo-physical properties of water-based novel Ag/ZnO hybrid nanofuids. J Therm Anal Calorim. 2018;134:1493–504.

Gupta SK, Misra RD. An experimental investigation on pool boiling heat transfer enhancement using Cu–Al2O3 nano-composite coating. Experimental Heat Transf. 2019;32(2):133–58.

Gupta SK, Misra RD. Experimental study of pool boiling heat transfer on copper surfaces with Cu–Al2O3 nanocomposite coatings. Int Commun Heat Mass Transf. 2018;97:47–55.

Holman JP. Experimental methods for engineers. 7th ed. Tata McGraw Hill Education Private Limited; 2007.

Rohsenow WM. A method of correlating heat transfer data for surface boiling of liquids. ASME. 1952;74:969–76.

Xu J, Gan Y, Zhang D, Li X. Microscale boiling heat transfer in a micro-timescale at high heat fluxes. J Micromech Microeng. 2005;15:362–76.

Wei JJ, Honda H. Effects of fin geometry on boiling heat transfer from silicon chips with micro-pin-fins immersed in FC-72. Int J Heat Mass Transf. 2003;46:4059–70.

Kong X, Zhang Y, Wei J. Experimental study of pool boiling heat transfer on novel bistructured surfaces based on micro-pin-finned structure. Exp Therm Fluid Sci. 2018;91:9–19.

Sarangi S, Weibel JA, Garimella SV. Quantitative evaluation of the dependence of pool boiling heat transfer enhancement on sintered particle coating characteristics. J Heat Transf. 2017;139:021502.

Cooke D, Kandlikar SG. Pool boiling heat transfer and bubble dynamics over plain and enhanced microchannels. J Heat Transf. 2011;133(5):052902.

Das S, Kumar DS, Bhaumik S. Experimental study of nucleate pool boiling heat transfer of water on silicon oxide nanoparticle coated copper heating surface. Appl Therm Eng. 2016;96:555–67.

Das S, Saha B, Bhaumik S. Experimental study of nucleate pool boiling heat transfer of water by surface functionalization with crystalline TiO2 nanostructure. Appl Therm Eng. 2017;113:1345–57.

Kwark SM, Kumar R, Moreno G, Yoo J, You SM. Pool boiling characteristics of low concentration nanofluids. Int J Heat Mass Transf. 2010;53:972–81.

Betz AR, Xu J, Qiu H, Attinger D. Do surfaces with mixed hydrophilic and hydrophobic areas enhance pool boiling? Appl Phys Lett. 2010;97:141909.

Bo S, Yi-Biao W, Kai C. Pool boiling heat transfer enhancement with copper nanowire arrays. Appl Therm Eng. 2015;75:115–21.

Acknowledgement

The authors gratefully acknowledge to Add Nano Synthesis Lab, Bangalore, India, for providing material synthesis facility, and NIT, Silchar, India, for financial support.

Funding

This project was not funded.

Author information

Authors and Affiliations

Contributions

G involved in problem identification, experimentation, and main manuscript drafting; M involved in mentoring this work and manuscript drafting.

Corresponding author

Ethics declarations

Conflict of interest

There are no disclosed conflicts of interest for the authors.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Gupta, S.K., Misra, R.D. Experimental pool boiling heat transfer analysis through novel ZnO-coated Cu (Cu@ZnO nanoparticle) hybrid nanofluid boiling on the fin tops of different microchannels. J Therm Anal Calorim 148, 12247–12267 (2023). https://doi.org/10.1007/s10973-023-12462-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10973-023-12462-0