Abstract

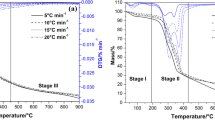

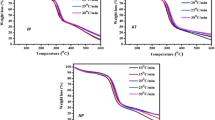

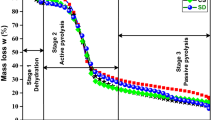

Litchi tree is planted in several countries of the world for its juicy fruit. For the estimated total annual global litchi production of ~ 2.7 million tons, around ~ 0.54 million tons of seeds as well as a sizeable amount of skin are generated as waste. This renewable waste biomass can be effectively used as the feedstock for recovering energy and obtaining several value-added products. In the present work, the fuel and thermochemical characteristics and thermal degradation behavior of acid- and alkali-treated litchi seed biomass were systematically investigated and compared for the first time. The average and maximum rate of mass losses, peak temperature and pyrolysis factor had been evaluated to assess the reactivity of the treated biomass. It had been observed that acid and alkali treatments improved the higher heating value and changed the thermal degradation behavior. The thermogravimetric (TG)/differential thermogravimetric analysis (DTG) data obtained at the heating rates of 20, 25 and 30 °C min−1 were used to evaluate the kinetic and thermodynamic parameters using iso-conversional models of Flynn–Wall–Ozawa, Kissinger–Akahira–Sunose, Tang and Starink. The Criado method had been used to elucidate the prevailing thermal degradation reaction mechanisms at different fractional conversions. The average activation energy of the acid-treated biomass increased, and that of the alkali-treated biomass decreased compared to that of the untreated biomass.

Graphical abstract

Similar content being viewed by others

References

Zhao L, Wang K, Wang K, Zhu J, Hu Z. Nutrient components, health benefits, and safety of litchi (Litchi chinensis Sonn.): a review. Compr Rev Food Sci Food Saf. 2020;19:2139–63.

Menzel C, The Physiology of Growth and Crop** in Lychee. Proc I Int Symp Litchi Longan Eds H Huang C Menzel Acta Hort 558, ISHS 2001. 2021;5:204–10.

Chena HB, Huang XM. Overview of litchi production in the world with specific reference to China. Acta Hortic. 2014;1029:25–34.

Punia S, Kumar M. Litchi (Litchi chinenis) seed: Nutritional profile, bioactivities, and its industrial applications. Trends Food Sci Technol. 2021;108:58–70. https://doi.org/10.1016/j.tifs.2020.12.005.

Anwar F, Mahmood T, Mehmood T, Aladedunye F. Composition of fatty acids and tocopherols in cherry and lychee seed oils. J Adv Biol. 2014;5:586–93.

Koul B and Singh J, The lychee biotechnology. Lychee Biol. Biotechnol. 2017.

Li L, Cao G, Zhu R. Adsorption of Cr(VI) from aqueous solution by a litchi shell-based adsorbent. Environ Res. 2020. https://doi.org/10.1016/j.envres.2020.110356.

Jaiswal P, Kumar KJ. Physicochemical properties and release characteristics of starches from seeds of Indian Shahi Litchi. Int J Biol Macromol. 2015;79:256–61. https://doi.org/10.1016/j.ijbiomac.2015.04.050.

Wang H, Srinivasan R, Yu F, Steele P, Li Q, Mitchell B. Effect of acid, alkali, and steam explosion pretreatments on characteristics of bio-oil produced from pinewood. Energy Fuels. 2011;25:3758–64.

Orzaya, Litchi seed extracts. ORYZA OIL FAT Chem CO, LTD. 2007

De Rezende Queiroz E, Patto De Abreu CM, Da K, Oliveira S, De V, Ramos O, et al. Bioactive phytochemicals and antioxidant activity in fresh and dried lychee fractions 1 Fitoquímicos bioativos e atividade antioxidante de frações de lichia frescas e secas. 46:163–9. www.ccarevista.ufc.br

Mp R, Re J, Moa R, Bmt H, Of G, Cmp S, et al. Nutri Food Sci Int J Phenolic compounds in the pulp, pericarp and seed of litchi (litchi Chinensis Sonn.) in different stages of Maturation. Nutr Food Sci Int J. 2019;8.

Tian H, Wang K, Lan H, Wang Y, Hu Z, Zhao L. Effect of hybrid gelator systems of beeswax-carrageenan-xanthan on rheological properties and printability of litchi inks for 3D food printing. Food Hydrocoll. 2021;113:106482. https://doi.org/10.1016/j.foodhyd.2020.106482.

Tian H, Wang K, Lan H, Wang Y, Hu Z, Zhao L. Effect of hybrid gelator systems of beeswax-carrageenan-xanthan on rheological properties and printability of litchi inks for 3D food printing. Food Hydrocoll. 2021;113:106482.

Bhatnagar A, Minocha AK. Assessment of the biosorption characteristics of lychee (Litchi chinensis) peel waste for the removal of Acid Blue 25 dye from water. Environ Technol. 2010;31:97–105.

Chanda S, Shanmugam S, Pottipadu MJ, Thiagaraja YR. Adsorption of Aniline Blue from Aqueous Solution Using Litchi chinensis Peel: Kinetic and Equilibrium Studies. J Environ Sci Technol. 2019;12:235–41.

Jasper PM, Sumithra S, Madakka M. Adsorption of Erichrome Black T from wastewater by Litchi chinensis. J Emerg Technol Innovat Res. 2021;8:2060–74.

Jegede MM, Durowoju OS, Edokpayi JN. Sequestration of hazardous dyes from aqueous solution using raw and modified agricultural waste. Adsorpt Sci Technol. 2021;2021:1–21.

Ma J, Hou L, Li P, Zhang S, Zheng X. Modified fruit pericarp as an effective biosorbent for removing azo dye from aqueous solution: study of adsorption properties and mechanisms. Environ Eng Res Korean Soc Environ Eng. 2022;27:2.

Ansari TM, Shaheen S, Manzoor S, Naz S, Hanif MA. Litchi chinensis peel biomass as green adsorbent for cadmium (Cd) ions removal from aqueous solutions. Desalin Water Treat. 2020;173:343–50.

Arul Manikandan N, Alemu AK, Goswami L, Pakshirajan K, Pugazhenthi G. Waste litchi peels for Cr(VI) removal from synthetic wastewater in batch and continuous systems: sorbent characterization, regeneration and reuse study. J Environ Eng. 2016;142:4016001C.

Yi Y, Lv J, Liu Y, Wu G. Synthesis and application of modified Litchi peel for removal of hexavalent chromium from aqueous solutions. J Mol Liq. 2017;225:28–33. https://doi.org/10.1016/j.molliq.2016.10.140.

Li P, **e Y, Zeng Y, Hu W, Kang Y, Li X, et al. Bioconversion of welan gum from kitchen waste by a two-step enzymatic hydrolysis pretreatment. Appl Biochem Biotechnol. 2017;183:820–32.

Li MF, Yang S, Sun RC. Recent advances in alcohol and organic acid fractionation of lignocellulosic biomass. Bioresour Technol. 2016;200:971–80. https://doi.org/10.1016/j.biortech.2015.10.004.

Shrestha A, Poudel BR, Silwal M, Pokhrel MR. Adsorptive removal of phosphate onto iron loaded litchi chinensis seed waste. J Inst Sci Technol. 2019;23:81–7.

Foletto VS, Ferreira AB, da Cruz Severo E, Collazzo GC, Foletto EL, Dotto GL. Iron-based adsorbent prepared from Litchi peel biomass via pyrolysis process for the removal of pharmaceutical pollutant from synthetic aqueous solution. Environ Sci Pollut Res. 2017;24:10547–56.

Mankar AR, Pandey A, Modak A, Pant KK. Pretreatment of lignocellulosic biomass: a review on recent advances. Bioresour Technol. 2021;334:125235. https://doi.org/10.1016/j.biortech.2021.125235.

Zhu Z, Rezende CA, Simister R, McQueen-Mason SJ, Macquarrie DJ, Polikarpov I, et al. Efficient sugar production from sugarcane bagasse by microwave assisted acid and alkali pretreatment. Biomass Bioenerg. 2016;93:269–78. https://doi.org/10.1016/j.biombioe.2016.06.017.

Kumar B, Bhardwaj N, Agrawal K, Chaturvedi V, Verma P. Current perspective on pretreatment technologies using lignocellulosic biomass: An emerging biorefinery concept. Fuel Process Technol. 2020;199:106244.

Conag AT, Villahermosa JER, Cabatingan LK, Go AW. Energy for sustainable development energy densification of sugarcane leaves through torrefaction under minimized oxidative atmosphere. Energy Sustain Develop. 2018;42:160–9.

Mann BF, Chen H, Herndon EM, Chu RK, Tolic N, Portier EF, et al. Indexing permafrost soil organic matter degradation using high-resolution mass spectrometry. PLoS ONE. 2015;10:1–16.

Saeed S, Saleem M, Durrani A. Thermal performance analysis of sugarcane bagasse pretreated by ionic liquids. J Mol Liq. 2020;312:113424. https://doi.org/10.1016/j.molliq.2020.113424.

Ashraf A, Sattar H, Munir S. Thermal decomposition study and pyrolysis kinetics of coal and agricultural residues under non-isothermal conditions. Fuel. 2019;235:504–14. https://doi.org/10.1016/j.fuel.2018.07.120.

Ozawa T. A new method of analyzing thermogravimetric data. Bull Chem Soc JPN. 1965;38:1881–6. https://doi.org/10.1246/bcsj.38.1881.

Akahira T, Sunose T. Method of determining activation deterioration constant of electrical insulating materials. Res Report Chiba Inst Technol. 1971;16:22–3.

Wanjun T, Cunxin W, Donghua C. An investigation of the pyrolysis kinetics of some aliphatic amino acids. Jounral Anal Appl Pyrol. 2006;75:49–53.

Starink MJ. The determination of activation energy from linear heating rate experiments: A comparison of the accuracy of isoconversion methods. Thermochim Acta. 2003;404:163–76.

Ahmad MS, Al-ayed O, Sajjad M, Muhammad A, Mehmood A, Ye G. Thermogravimetric analyses revealed the bioenergy potential of Eulaliopsis binata Thermogravimetric analyses revealed the bioenergy potential. J Therm Anal Calorim. 2017;130:1237–47.

Criado JM, Sánchez-Jiménez PE, Pérez-Maqueda LA. Critical study of the isoconversional methods of kinetic analysis. J Therm Anal Calorim. 2008;92:199–203.

Motghare KA, Rathod AP, Wasewar KL, Labhsetwar NK. Comparative study of different waste biomass for energy application. Waste Manag. 2016;47:40–5.

Cai J, He Y, Yu X, Banks SW, Yang Y, Zhang X, et al. Review of physicochemical properties and analytical characterization of lignocellulosic biomass. Renew Sustain Energy Rev. 2017;76:309–22.

Liu C, Liu J, Evrendilek F, **e W, Kuo J, Buyukada M. Bioenergy and emission characterizations of catalytic combustion and pyrolysis of litchi peels via TG-FTIR-MS and Py-GC/MS. Renew Energy. 2020;148:1074–93. https://doi.org/10.1016/j.renene.2019.09.133.

Mishra RK, Kumar V, Mohanty K. Pyrolysis kinetics behaviour and thermal pyrolysis of Samanea saman seeds towards the production of renewable fuel. J Energy Inst. 2020;93:1148–62. https://doi.org/10.1016/j.joei.2019.10.008.

Liu C, Liu J, Evrendilek F, **e W, Kuo J. Bioenergy and emission characterizations of catalytic combustion and pyrolysis of litchi peels via TG-FTIR-MS and Py-GC / MS. Renew Energy. 2020;148:1074–93.

M. Fantini. Biomass availability, potential and Charateristics. Lect. Notes Energy. 2017. https://springer.longhoe.net.0000159e0993.han.p.lodz.pl/content/pdf/10.1007%2F978-3-319-48288-0.pdf

El-Sayed SA, Mostafa ME. Pyrolysis characteristics and kinetic parameters determination of biomass fuel powders by differential thermal gravimetric analysis (TGA/DTG). Energy Convers Manag. 2014;85:165–72. https://doi.org/10.1016/j.enconman.2014.05.068.

Moghtaderi B. A study on the char burnout characteristics of coal and biomass blends. Fuel. 2007;86:2431–8.

Mishra RK, Mohanty K. Bioresource Technology Pyrolysis kinetics and thermal behavior of waste sawdust biomass using thermogravimetric analysis. Bioresour Technol. 2018;251:63–74. https://doi.org/10.1016/j.biortech.2017.12.029.

Mehmood MA, Ahmad MS. Pyrolysis and kinetic analyses of Camel grass ( Cymbopogon schoenanthus ) for bioenergy. Bioresour Technol. 2017;228:18–24. https://doi.org/10.1016/j.biortech.2016.12.096.

Gupta GK, Mondal MK. Kinetics and thermodynamic analysis of maize cob pyrolysis for its bioenergy potential using thermogravimetric analyzer. J Therm Anal Calorim. 2019. https://doi.org/10.1007/s10973-019-08053-7.

Gan DKW, Loy ACM, Chin BLF, Yusup S, Unrean P, Rianawati E, et al. Kinetics and thermodynamic analysis in one-pot pyrolysis of rice hull using renewable calcium oxide based catalysts. Bioresour Technol. 2018;265:180–90.

Darren G. Kinetic and thermodynamic analysis in one-pot pyrolysis of rice hull using renewable calcium oxide based catalysts. Bioresour Technol. 2019;265:180–90.

Acknowledgements

Authors are grateful to the Head of the Department and Co-coordinator of the Sophisticated Laboratory Department of Chemical Engineering & Technology, Indian Institute of Technology (BHU) Varanasi. One of the authors (MK) is grateful to the MHRD, New Delhi, for the award of a senior research fellowship.

Funding

The authors declare that no funds, grants, or other support was received during the preparation of this manuscript.

Author information

Authors and Affiliations

Contributions

MK did a literature search, ran all the experiments, assessed the results and wrote the first version of the manuscript. SNU assisted in the design of the experiments, data analysis and paper revision and oversaw the entire project. PKM assisted in the design of the experiments, data analysis and paper revision and oversaw the entire project. MB assisted in revision of the paper and characterization of the samples. RY assisted in the experiments. AKP assisted in the experiments.

Corresponding author

Ethics declarations

Conflict of interests

The authors declare no competing interests.

Consent to participate

Not applicable.

Consent for publication

Not applicable.

Ethical approval

Not applicable.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Kumar, M., Yadav, R., Patel, A.K. et al. Effect of chemical treatment on thermal degradation behavior of litchi seed biomass. J Therm Anal Calorim 148, 6927–6944 (2023). https://doi.org/10.1007/s10973-023-12176-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10973-023-12176-3