Abstract

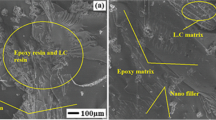

In this article, Grewia Optiva fiber (GOF) has been reinforced with epoxy and hybrid (epoxy-Lannea Coromandelica gum) resins. The biocomposite has been fabricated with 5, 10, and 15 weight% of continuous and discontinuous GOFs. The effect of fiber surface treatment has been examined on the mechanical properties of GOF. Additionally, the mechanical properties along with physicochemical, morphological, and thermal characterization have been determined for GOF reinforced composites. The results have revealed that GOF treated with 5% NaOH has shown superior tensile strength. Also, the increase in fiber content has increased the water absorption, and it has been maximum for 15 wt% GOF reinforced hybrid resin composites. Further, the stress-strain behaviors under tensile and flexural load have confirmed that 15 wt% continuous GOF reinforcement with epoxy resin has shown maximum tensile strength and flexural strength. In Charpy impact test, 15 wt% GOF reinforcement with hybrid resin has shown the best results compared to their counterparts. The spectroscopy has confirmed the interaction between resins and GOF. The morphological analysis has confirmed the porous structure and inter-connected open cavities with unique hollow and multiscale structures of GOF. The fractured surface of composites under tensile and flexural loading has confirmed the fiber-matrix debonding, fiber breaking, and microcracking. Also, no gaps or pull outs confirming the good interfacial adhesion between fiber and matrix. The thermal analyses have shown the low thermal stability of composites and the lower values of glass transition temperature for composites in comparison to pure resins. Further, this work can expose a fresh way to implement locally accessible eco-friendly natural fiber and resins to produce high-performance biocomposites. The utilization of agricultural by-product as a sustainable green composite can resolve the problem of disposal of these materials and maintain an eco-friendly environment. These composites could be suitable for buildings, automotive parts, sound barriers, marine parts, etc.

Similar content being viewed by others

References

Abdul Khalil HPS, Bhat IUH, Jawaid M, Zaidon A, Hermawan D, Hadi YS (2012) Bamboo fibre reinforced biocomposites: a review. Mater Des 42:353–368. https://doi.org/10.1016/j.matdes.2012.06.015

Wong KJ, Zahi S, Low KO, Lim CC (2010) Fracture characterisation of short bamboo fibre reinforced polyester composites. Mater Des 31:4147–4154. https://doi.org/10.1016/j.matdes.2010.04.029

Nirmal U, Hashim J, Low KO (2012) Adhesive wear and frictional performance of bamboo fibres reinforced epoxy composite. Tribol Int 47:122–133. https://doi.org/10.1016/j.triboint.2011.10.012

Mukhopadhyay S, Fangueiro R, Arpaç Y, Şentürk Ü (2008) Banana fibers – variability and fracture behaviour. J Eng Fibers Fabr 3:39–45. https://doi.org/10.1177/155892500800300207

Singh V, Chauhan S, Singh B (2012) Mechanical behavior of banana fiber-based hybrid bio composites. J Mater Environ Sci 3:185–194. http://www.jmaterenvironsci.com

Raghavendra S, Lingaraju, Shetty PB, Mukunda PG (1970) Mechanical properties of short banana fiber reinforced natural rubber composites. Int J Innov Res Technol Sci Eng 2:1652–1655. https://13.232.72.61:8080/jspui/handle/123456789/388

Verma D, Gope P, Shandilya A, Gupta A, Maheshwari MK (2013) Coir fiber reinforcement and application in polymer composites: a review. J Mater Environ Sci 4:263–276. http://www.jmaterenvironsci.com/

Ali M (2011) Coconut fibre: a versatile material and its applications in engineering. J Civ Eng Constr Technol 2:189–197. https://doi.org/10.5897/JCECT.9000009

Ayrilmis N, Jarusombuti S, Fueangvivat V, Bauchongkol P, White RH (2011) Coir fiber reinforced polypropylene composite panel for automotive interior applications. Fibers Polym 12:919. https://doi.org/10.1007/s12221-011-0919-1

Arbelaiz A, Fernández B, Ramos JA, Retegi A, Llano-Ponte R, Mondragon I (2005) Mechanical properties of short flax fibre bundle/polypropylene composites: influence of matrix/fibre modification, fibre content, water uptake and recycling. Compos Sci Technol 65:1582–1592. https://doi.org/10.1016/j.compscitech.2005.01.008

Andersons J, Poriķe E, Spārniņš E (2009) The effect of mechanical defects on the strength distribution of elementary flax fibres. Compos Sci Technol 69:2152–2157. https://doi.org/10.1016/j.compscitech.2009.05.010

Aydın M, Tozlu H, Kemaloglu S, Aytac A, Ozkoc G (2011) Effects of Alkali treatment on the properties of short flax fiber–poly (lactic acid) eco-composites. J Polym Environ 19:11–17. https://doi.org/10.1007/s10924-010-0233-9

Garkhail SK, Heijenrath RWH, Peijs T (2000) Mechanical properties of natural-fibre-mat- reinforced thermoplastics based on flax fibres and polypropylene. Appl Compos Mater 7:351–372. https://doi.org/10.1023/A:1026590124038

Gon D, Das K, Paul P, Maity S (2012) Jute composites as wood substitute. Int J Text Sci 1:84–93. https://doi.org/10.5923/j.textile.20120106.05

Doan T-T-L, Brodowsky H, Mäder E (2012) Jute fibre/epoxy composites: Surface properties and interfacial adhesion. Compos Sci Technol 72:1160–1166. https://doi.org/10.1016/j.compscitech.2012.03.025

Al-Kafi A, Abedin MZ, Beg MDH, Pickering KL, Khan MA (2006) Study on the mechanical properties of jute/glass fiber-reinforced unsaturated polyester hybrid composites: Effect of surface modification by ultraviolet radiation. J Reinf Plast Compos 25:575–588. https://doi.org/10.1177/0731684405056437

Gassan J, Bledzki AK (2000) Possibilities to improve the properties of natural fiber reinforced plastics by fiber modification – jute polypropylene composites –. Appl Compos Mater 7:373–385. https://doi.org/10.1023/A:1026542208108

Akil HM, Omar MF, Mazuki AAM, Safiee S, Ishak ZAM, Abu Bakar A (2011) Kenaf fiber reinforced composites: a review. Mater Des 32:4107–4121. https://doi.org/10.1016/j.matdes.2011.04.008

Malik K, Ahmad F, Gunister E (2021) A review on the kenaf fiber reinforced thermoset composites. Appl Compos Mater 28:491–528. https://doi.org/10.1007/s10443-021-09871-5

Udoeyo F, Ayobami A (2012) Characteristics of kenaf fiber-reinforced mortar composites. Int J Res Rev Appl Sci 12:18–26

Hao A, Zhao H, Chen JY (2013) Kenaf/polypropylene nonwoven composites: the influence of manufacturing conditions on mechanical, thermal, and acoustical performance. Compos B Eng 54:44–51. https://doi.org/10.1016/j.compositesb.2013.04.065

Ramires EC, Megiatto JD Jr, Gardrat C, Castellan A, Frollini E (2010) Biobased composites from glyoxal–phenolic resins and sisal fibers. Bioresour Technol 101:1998–2006. https://doi.org/10.1016/j.biortech.2009.10.005

Zhong J (2007) Mechanical properties of sisal fibre reinforced urea-formaldehyde resin composites. Express Polym Lett 1:681–687. https://doi.org/10.3144/expresspolymlett.2007.93

Li Z, Zhou X, Pei C (2011) Effect of sisal fiber surface treatment on properties of sisal fiber reinforced polylactide composites. Int J Polym Sci 2011:1–7. https://doi.org/10.1155/2011/803428

El-Tayeb NSM (2008) A study on the potential of sugarcane fibers/polyester composite for tribological applications. Wear 265:223–235. https://doi.org/10.1016/j.wear.2007.10.006

Miléo PC, Mulinari DR, Baptista CARP, Rocha GJM, Goncalves AR (2011) Mechanical behaviour of polyurethane from castor oil reinforced sugarcane straw cellulose composites. Procedia Eng 10:2068–2073. https://doi.org/10.1016/j.proeng.2011.04.342

Cerqueira EF, Baptista CARP, Mulinari DR (2011) Mechanical behaviour of polypropylene reinforced sugarcane bagasse fibers composites. Procedia Eng 10:2046–2051. https://doi.org/10.1016/j.proeng.2011.04.339

Singha AS, Thakur VK (2010) Synthesis and characterization of short grewia optiva fiber-based polymer composites. Polym Compos 31:459–470. https://doi.org/10.1002/pc.20825

Singha AS, Thakur VK (2009) Grewia optiva fiber reinforced novel, low cost polymer composites. E-J Chem 6:71–76. https://doi.org/10.1155/2009/642946

Singha AS, Rana AK (2012) Effect of surface modification of grewia optiva fibres on their physicochemical and thermal properties. Bull Mater Sci 35:1099–1110. https://doi.org/10.1007/s12034-012-0400-9

Singha AS, Thakur VK (2009) Synthesis and characterizations of silane treated grewia optiva fibers. Int J Polym Anal Charact 14:301–321. https://doi.org/10.1080/10236660902871470

Singha AS, Thakur VK (2008) Synthesis and characterization of grewia optiva fiber-reinforced pf-based composites. Int J Polym Mater Polym Biom 57:1059–1074. https://doi.org/10.1080/00914030802257800

Thakur VK, Singha AS (2010) Evaluation of grewia optiva fibers as reinforcement in polymer biocomposites. Polym Plast Technol Eng 49:1101–1107. https://doi.org/10.1080/03602559.2010.496390

Singha AS, Rana AK (2012) Effect of graft copolymerization on mechanical, thermal, and chemical properties of grewia optiva/unsaturated polyester biocomposites. Polym Compos 33:1403–1414. https://doi.org/10.1002/pc.22267

Faisal M Guide to composites. http://www.netcomposites.com/education.asp?sequence=2

Mate C, Mishra S (2020) Exploring the potential of moi gum for diverse applications: a review. J Polym Environ 28:1579–1591. https://doi.org/10.1007/s10924-020-01709-8

Kumar T, Jain V (2015) Appraisal of total phenol, flavonoid contents, and antioxidant potential of folkloric lannea coromandelica using in vitro and in vivo assays. Scientifica (Cairo) 2015:1–13. https://doi.org/10.1155/2015/203679

Vadivel K, Thangabalan B, Narayana KV, Chetanajessygrace B, Kumar DP, Babu SM (2012) Preliminary phytochemical evaluation of leaf extracts of lannea corommandelica L. Int J Pharmacol Res 2:64–68

Li X, Tabil L, Panigrahi S (2007) Chemical treatments of natural fiber for use in natural fiber-reinforced composites: a review. J Polym Environ 15:25–33. https://doi.org/10.1007/s10924-006-0042-3

Ibrahim NA, Hadithon KA, Abdan K (2010) Effect of fiber treatment on mechanical properties of kenaf fiber-ecoflex composites. J Reinf Plast Compos 29:2192–2198. https://doi.org/10.1177/0731684409347592

Bhagia S, Ďurkovič J, Lagaňa R, Kardošová M, Kačík F, Cernescu A, Schäfer P, Yoo CG, Ragauskas AJ (2022) Nanoscale FTIR and mechanical map** of plant cell walls for understanding biomass deconstruction. ACS Sustainable Chem Eng 10:3016–3026. https://doi.org/10.1021/acssuschemeng.1c08163

Sgriccia N, Hawley MC, Misra M (2008) Characterization of natural fiber surfaces and natural fiber composites. Compos A: Appl Sci Manuf 39:1632–1637. https://doi.org/10.1016/j.compositesa.2008.07.007

Ribeiro MP, Neuba LM, Silveira PHPM, Luz FS, Figueiredo ABHS, Monteiro SN, Moreira MO (2021) Mechanical, thermal and ballistic performance of epoxy composites reinforced with cannabis sativa hemp fabric. J Mater Res Technol 12:221–233. https://doi.org/10.1016/j.jmrt.2021.02.064

Cecen V, Seki Y, Sarikanat M, Tavman I (2008) FTIR and SEM analysis of polyester- and epoxy‐based composites manufactured by VARTM process. J Appl Polym Sci 108:2163–2170. https://doi.org/10.1002/app.27857

Robledo-Ortíz JR, González-López ME, Rodrigue D, Gutiérrez-Ruiz JF, Prezas-Lara F, Pérez-Fonseca AA (2020) Improving the compatibility and mechanical properties of natural fibers/green polyethylene biocomposites produced by rotational molding. J Polym Environ 28:1040–1049. https://doi.org/10.1007/s10924-020-01667-1

Roszowska-Jarosz M, Masiewicz J, Kostrzewa M, Kucharczyk W, Żurowski W, Kucińska-Lipka J, Przybyłek P (2021) Mechanical properties of bio-composites based on epoxy resin and nanocellulose fibres. Materials 14:3576. https://doi.org/10.3390/ma14133576

Saehana S, Darsikin M (2021) Physics characteristic of Lanea coromandelica (Houtt) Merr. Based polymer and its potential application. Mater Today: Proc 44:3327–3330. https://doi.org/10.1016/j.matpr.2020.11.538

Asim M, Paridah M, Chandrasekar M, Shahroze RM, Jawaid M, Nasir M, Siakeng R (2020) Thermal stability of natural fibers and their polymer composites. Iran Polym J 29:1–24. https://doi.org/10.1007/s13726-020-00824-6

Tarawneh MA, Saraireh SA, Chen RS, Ahmad SH, Al-Tarawni MAM, Yu LJ, Alsobhi BO, Hui D (2020) Mechanical reinforcement with enhanced electrical and heat conduction of epoxy resin by polyaniline and graphene nanoplatelets. Nanotechnol Rev 9:1550–1561. https://doi.org/10.1515/ntrev-2020-0118

Nur Diyana AF, Khalina A, Sapuan MS, Lee CH, Aisyah HA, Nurazzi MN, Ayu RS Physical, mechanical, and thermal properties and characterization of natural fiber composites reinforced poly (lactic acid): Miswak (Salvadora Persica L.) Fibers.Int J Polym Sci2022:1–20. https://doi.org/10.1155/2022/7253136

Neto JSS, de Queiroz HFM, Aguiar RAA, Banea MD (2021) A review on the thermal characterisation of natural and hybrid fiber composites. Polymers 13:4425. https://doi.org/10.3390/polym13244425

Acknowledgements

First author thanks the Ministry of Education (MOE), Government of India for giving Ph.D. fellowship.

Funding

No funds, grants, or other support was received for this work.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Ethics approval

This work has not been submitted and under consideration for publication anywhere else.

Financial interests and non-financial interests

The authors have no relevant financial or non-financial interests to disclose.

Competing interests

The authors have no competing interests to declare.

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Kalauni, K., Pawar, S.J. Physicochemical, mechanical, morphological, and thermal characterization of Grewia Optiva fiber reinforced epoxy and hybrid (epoxy-Lannea Coromandelica gum) resins composite. J Polym Res 30, 202 (2023). https://doi.org/10.1007/s10965-023-03583-z

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s10965-023-03583-z