Abstract

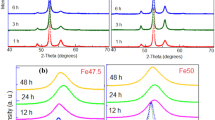

The structure, morphological, thermal, and magnetic properties of the mechanically alloyed Fe90Al8C2 (wt.%) powders were investigated by using X-ray diffraction (XRD), scanning electron microscopy, differential scanning calorimetry, and vibrating sample magnetometry, respectively. The XRD analysis reveals a mixture of three disordered solid solutions (Fe1-SS, Fe2-SS, and Fe3-SS) with different lattice parameters and crystallite sizes. The saturation magnetization swings between 128 and 133 emu/g, and the coercivity is between 90 and 62 Oe. After heating to 1100 °C, the XRD results show the formation of nanocrystalline (Fe, Al)3C-type carbide and two Fe-type solid solutions. The heated samples exhibit enhanced magnetic properties with enhanced saturation magnetization (Ms = 132.97–179.76 emu/g) and reduced coercivity (Hc = 46.59–53.63 Oe). The composite Fe-Al-C structure can be considered a potential candidate for soft magnetic applications.

Similar content being viewed by others

Data Availability

The datasets generated during and/or analyzed during the current study are available from the corresponding author on reasonable request.

References

Zuazo, I., Hallstedt, B., Lindahl, B., Selleby, M., Soler, M., Etienne, A., Perlade, A., Hasenpouth, D., Massardier-Jourdan, V., Cazottes, S., Kleber, X.: Low-density steels: complex metallurgy for automotive applications. JOM J. Mine. Met. Mater. Soc. 66(19), 1747–1758 (2014)

Devan, J.H., Tortorelli, P.F.: Oxidation/sulfidation of iron-aluminium alloys. Mater. High. Temp. 11(11–4), 30–35 (1993)

Rao, V.S., Baligidad, R., Raja, V.: Effect of Al content on oxidation behaviour of ternary Fe-Al-C alloys. Intermetallics 10(11), 73–84 (2002)

Wyslocki, J.J.: Magnetic properties, microstructure and magnetic domain structure in anisotropic Fe-Al-C permanent magnet. Phys. Status Solidi (A) 151(12), 421–433 (1995)

Giza, K., Bala, H., Wysłocki, J.J., Szymura, S.: Corrosion resistance of the Fe-Al- C permanent magnet alloy. Intermetallics 6(15), 357–362 (1998)

Wysłocki, J.J.: Magnetic properties of the anisotropic Fe-Al-C permanent magnet within the temperature range of 4.2 to 1100 K. Phys. Status Solidi (A) 153(12), 487–500 (1996)

Bonnenberg, D., Burzo E., Kirchmayr, H.R., Nakamichi, T., Wijn, H.P.J.: Magnetic alloys for technical applications. Hard Magnetic Alloys, Landolt-Börnstein III 19 i2, (1992)

Wyłǒki, J.J.: Coercivity mechanism in the anisotropic Fe-Al-C permanent magnet. Phys. Status Solidi (A) 155(12), 485–495 (1996)

Schneider, A., Falat, L., Sauthoff, G., Frommeyer, G.: Microstructures and mechanical properties of Fe3Al-based Fe–Al–C alloys. Intermetallics 13(12), 1322–1331 (2005)

Jiménez, J.J.A., Frommeyer, G.: The ternary iron aluminum carbides. J. Alloy. Compd. 509, 2729–2733 (2011)

Weiyan, L., Lin, L., Li, W., Yanlin, H., Shuigen, H.: Thermodynamic assessment and experimental investigation of Fe-Al-C system. J. Mater. Sci. Technol. 24, 771–774 (2009)

Phan, A.T., Paek, M.-K., Kang, Y.-B.: Phase equilibria and thermodynamics of the Fe–Al–C system: critical evaluation, experiment and thermodynamic optimization. Acta Mater. 79, 1–15 (2014)

Suryanarayana, C., Al-Joubori, A.A., Wang, Z.: Nanostructured materials and nanocomposites by mechanical alloying: an overview. Metal Mater. Int. 1–13 (2021)

Suryanarayana, C.: Mechanical alloying: a novel technique to synthesize advanced materials. Encyclopedia of Iron, Steel, and Their Alloys, pp. 159–177 (2019)

Su, S.S., Chang, I.: Review of production routes of nanomaterials. Commercialization of nanotechnologies–a case study approach, vols. 1 sur 2, pp. 15–29. Springer, Cham, 2018. https://doi.org/10.1007/978-3-319-56979-6_2

Zhang, D.L., Adam, G., Ammundsen, B.: Phase formation during mechanical alloying and subsequent low-temperature heat treatment of Al–27.4 at% Fe–28.7 at%C powders. J. Alloys. Compd. 340(1–2), 226–230 (2002)

Minamino, Y., Koizumi, Y., Tsuji, N., Hirohata, N., Mizuuchi, K., Ohkanda, Y.: Bulk Fe-Al-C nanoalloys made by mechanically alloying with subsequent spark plasma sintering and their mechanical properties. Solid State Phenom. 101(11), (2005)

Takeuchi, A., Inoue, A.: Classification of bulk metallic glasses by atomic size difference, heat of mixing and period of constituent elements and its application to characterization of the main alloying element. Mater. Trans. 46(12), 2817–2829 (2005)

Ungár, T., Schafler, E., Gubicza, J.: Nanomaterials determined by X-ray line-profile analysis. Bulk Nanostructured Materials, pp. 361–383 (2009)

Lutterotti, L.: A Rietveld analysis program designed for the internet and experiment integration. Acta Crystallogr. A 56, 54 (2000)

Rietveld, H.M.: The Rietveld method. Phys. Scr. 89(19), 098002 (2014)

Zeng, Q., Baker, I.: Magnetic properties and thermal ordering of mechanically alloyed Fe–40 at% Al. Intermetallics 14(14), 396–405 (2006)

Oleszak, D., Shingu, P.H.: Mechanical alloying in the Fe-Al system. Mater. Sci. Eng. A 181, 1217–1221 (1994)

Wang, G., Xu, Y., Qian, P., Su, Y.: Vacancy concentration of films and nanoparticles. Comput. Mater. Sci. 173, 109416 (2019)

Suryanarayana, C., Sharma, S.: Lattice contraction during amorphization by mechanical alloying. J. Appl. Phys. 104(110), 103503 (2008)

Lu, L., Lai, M.O., Zhang, S.: Diffusion in mechanical alloying. J. Mater. Process. Technol. 67(1–3), 100–104 (1997)

Lemdani, F., Azzaz, M., Taïbi, K., Lounis, A.: Effect of mechanical alloying on the structure and properties of iron powders. Defect and Diffusion Forum, Trans Tech Publications Ltd. 364, 132–138 (2015)

Azzaza, S., Alleg, S., Suňol, J.J.: Microstructure characterization and thermal stability of the ball milled iron powders. J. Therm. Anal. Calorim. 119(12), 1037–1046 (2015)

Alleg, S., Souilah, S., Suñol, J.J.: Thermal stability of the nanostructured powder mixtures prepared by mechanical alloying. In Applications of Calorimetry in a Wide Context-Differential Scanning Calorimetry, Isothermal Titration Calorimetry and Microcalorimetry. IntechOpen (2013)

Plascak, J.A., Zamora, L.E., Alcazar, G.P.: Ising model for disordered ferromagnetic Fe−Al alloys. Phys. Rev. B 61(15), 3188 (2000)

Amils, X., Nogués, J., Surinach, S., Muñoz, J.S., Lutterotti, L., Gialanella, S., Baró, M.D.: Structural, mechanical and magnetic properties of nanostructured FeAl alloys during disordering and thermal recovery. Nanostruct. Mater. 11(16), (1999)

Gialanella, S., Amils, X., Baro, M.D., Delcroix, P., Le Caër, G., Lutterotti, L., Suriñach, S.: Microstructural and kinetic aspects of the transformations induced in a FeAl alloy by ball-milling and thermal treatments. Acta Mater. 46(19), 33 (1998)

Krasnowski, M.: Phase transformations during mechanical alloying and subsequent heating of FeAlB powders. J. Alloys Compd. 706, 110–115 (2017)

Zuhailawati, H., Geok, T.C., Basu, P.: Microstructure and hardness characterization of mechanically alloyed Fe–C elemental powder mixture. Mater. Des. 31(14), 2211–2215 (2010)

Chaira, D., Mishra, B.K., Sangal, S.: Efficient synthesis and characterization of iron carbide powder by reaction milling. Powder Technol. 191(11–2), 149–154 (2009)

Acknowledgements

This work was supported by the Algerian General Directory of Scientific Research and Technological Development (DGRSDT). The authors thank Mr. Foued Khammaci from the LM2S laboratory for the VSM measurements.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Competing Interests

The authors declare no competing interests.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Lemdani, F., Alleg, S., Mechri, H. et al. Structure and Magnetic Properties of Mechanically Alloyed Fe90Al8C2 (wt.%) Powders. J Supercond Nov Magn 36, 207–215 (2023). https://doi.org/10.1007/s10948-022-06456-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10948-022-06456-6