Abstract

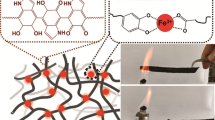

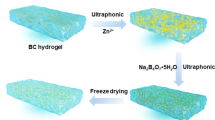

As the third generation of novel aerogels, cellulose aerogels exhibit broad applications in various fields, indicating its great development potential. Whereas the flammability and poor mechanical performance of cellulose aerogel restrict its practical application. Herein, a kind of flame retarded and reinforced aerogel was fabricated using cellulose nanofibrils (CNFs) and sodium alginate (SA) as compound matrix (CA) based on double cross-linking strategy. Boric acid (BA)/Ca2+ were used as synchronous flame retardants and cross-linking agents. FT-IR spectra of compound aerogels confirmed the occurrence of cross-linking reaction. Due to the formation of interpenetrating networks, especially the specific eggbox structure formed by the cross-linking between Ca2+ and SA, the double cross-linked specimen (CA/Ca/BA-3) exhibited decreased pore size and porosity, also resulting in the improved mechanical performance. The double cross-linked aerogel also exhibited excellent flame-resistant properties. The limiting oxygen index (LOI) of CA/Ca/BA-3 increased from 20.4 to 35.6%, and vertical combustion test (UL-94) rating reached V-0 level. The results of microcalorimetry showed that the maximum heat release rate (pHRR) and total heat release (THR) of CA/Ca/BA-3 decreased by 48% and 62% in comparison with control specimen (CS), respectively. The analysis of carbon residues showed that both condensed phase and gaseous phase flame-retardant mechanisms existed, and synergistic effect between BA and CaCO3 occurred during combustion. Moreover, the very low thermal conductivity of compound aerogels permitted their application as heat insulation materials. This investigation is helpful to promote the functionalization of cellulose aerogel while taking into account the increasingly stringent environmental requirements.

Similar content being viewed by others

Data Availability

Availability and transparency.

References

Liu K, Du H, Zheng T, Liu H, Zhang M, Zhang R, Li H, **e H, Zhang X, Ma M, Si C (2021) Recent advances in cellulose and its derivatives for oilfield applications. Carbohydr Polym 259:117740. https://doi.org/10.1016/j.carbpol.2021.117740

Taupichai S (2022) Recent development of plant-derived nanocellulose in polymer nanocomposite foams and multifunctional applications: a mini-review. Express Polym Lett 16:52–74. https://doi.org/10.3144/expresspolymlett.2022.5

Gupta P, Singh B, Agrawal AK, Maji PK (2018) Low density and high strength nanofibrillated cellulose aerogel for thermal insulation application. Mater Des 158:224–236. https://doi.org/10.1016/j.matdes.2018.08.031

Ma Z, Zhou P, Zhang L, Zhong Y, Sui X, Wang B, Ma Y, Feng X, Xu H, Mao Z (2021) A recyclable 3D g-C3N4 based nanocellulose aerogel composite for photodegradation of organic pollutants. Cellulose 28:3531–3547. https://doi.org/10.1007/s10570-021-03748-3

Chen S, Lu W, Han J, Zhong H, Xu T, Wang G, Chen W (2019) Robust three-dimensional g-C3N4@cellulose aerogel enhanced by cross-linked polyester fibers for simultaneous removal of hexavalent chromium and antibiotics. Chem Eng J 359:119–129. https://doi.org/10.1016/j.cej.2018.11.110

Seddiqi H, Oliaei E, Honarkar H, ** J, Geonzon LC, Bacabac RG, Klein-Nulend J (2021) Cellulose and its derivatives: towards biomedical applications. Cellulose 28:1893–1931. https://doi.org/10.1007/s10570-020-03674-w

Yang L, Mukhopadhyay A, Jiao Y, Yong Q, Chen L, **ng Y, Hamel J, Zhu H (2017) Ultralight, highly thermally insulating and fire resistant aerogel by encapsulating cellulose nanofibers with two-dimensional MoS2. Nanoscale 32:11341–11818. https://doi.org/10.1039/c7nr02243c

Wicklein B, Kocjan A, Salazar-Alvarez G, Carosio F, Camino G, Antonietti M, Bergstrom L (2015) Thermally insulating and fire-retardant lightweight anisotropic foams based on nanocellulose and graphene oxide. Nat Nanotechnol 10:277–283. https://doi.org/10.1038/nnano.2014.248

Guo W, Wang X, Zhang P, Liu J, Song L, Hu Y (2018) Nano-fibrillated cellulose-hydroxyapatite based composite foams with excellent fire resistance. Carbohydr Polym 195:71–78. https://doi.org/10.1016/j.carbpol.2018.04.063

Liu R, Dong X, **e S, Jia T, Xue Y, Liu J, Wei J, Guo A (2019) Ultralight, thermal insulating, and high-temperature-resistant mullite-based nanofibrous aerogels. Chem Eng J 360:464–472. https://doi.org/10.1016/j.cej.2018.12.018

Guo L, Chen Z, Lyu S, Feng F, Wang S (2018) Highly flexible cross-linked cellulose nanofibril sponge-like aerogels with improved mechanical property and enhanced flame retardancy. Carbohydr Polym 179:333–340. https://doi.org/10.1016/j.carbpol.2017.09.084

Ghanadpour M, Wicklein B, Carosio F, Wagberg L (2018) All-natural and highly flame-resistant freeze-cast foams based on phosphorylated cellulose nanofibrils. Nanoscale 10:4085–4095. https://doi.org/10.1039/c7nr09243a

Pei M, Peng X, Wan T, Fan P, Yang H, Liu X, Xu W, Zhou Y, **ao P (2021) Double cross-linked poly(vinyl alcohol) microcomposite hydrogels with high strength and cell compatibility. Eur Polym J 160:110786. https://doi.org/10.1016/j.eurpolymj.2021.110786

Ren J, Wang XM, Zhao LL, Li M, Yang W (2021) Double network gelatin/chitosan hydrogel effective removal of dyes from aqueous solutions. J Polym Environ 30:2007–2021. https://doi.org/10.1007/s10924-021-02327-8

Zhang J, Ji Q, Shen X, **a Y, Tan L, Kong Q (2011) Pyrolysis products and thermal degradation mechanism of intrinsically flame-retardant calcium alginate fibre. Polym Degrad Stabil 96:936–942. https://doi.org/10.1016/j.polymdegradstab.2011.01.029

Kuo CK, Ma PX (2001) Ionically crosslinked alginate hydrogels as scaffolds for tissue engineering: Part 1. Structure, gelation rate and mechanical properties. Biomaterials 22:511–521. https://doi.org/10.1016/s0142-9612(00)00201-5

Gao H, Duan B, Lu A, Deng H, Du Y, Shi X, Zhang L (2018) Fabrication of cellulose nanofibers from waste brown algae and their potential application as milk thickeners. Food Hydrocolloid 79:473–481. https://doi.org/10.1016/j.foodhyd.2018.01.023

**e M, Hu B, Wang Y, Zeng X (2014) Grafting of gallic acid onto chitosan enhances antioxidant activities and alters rheological properties of the copolymer. J Agric Food Chem 62(37):9128–9136. https://doi.org/10.1021/jf503207s

Deng W, Tang Y, Mao J, Zhou Y, Chen T, Zhu X (2021) Cellulose nanofibril as a crosslinker to reinforce the sodium alginate/chitosan hydrogels. Int J Biol Macromol 189:890–899. https://doi.org/10.1016/j.ijbiomac.2021.08.172

Zhang A, Zou Y, ** Y, Wang P, Zhang Y, Wu L, Zhang H (2021) Fabrication and characterization of bamboo shoot cellulose/sodium alginate composite aerogels for sustained release of curcumin. Int J Biol Macromol 192:904–912. https://doi.org/10.1016/j.ijbiomac.2021.10.027

Elanthikkal S, Gopalakrishnapanicker U, Varghese S, Guthrie JT (2010) Cellulose microfibres produced from banana plant wastes: isolation and characterization. Carbohydr Polym 80:852–859. https://doi.org/10.1016/j.carbpol.2009.12.043

Kumar A, Lee Y, Kim D, Rao KM, Kim J, Park S, Haider A, Lee DH, Han SS (2017) Effect of crosslinking functionality on microstructure, mechanical properties, and in vitro cytocompatibility of cellulose nanocrystals reinforced poly (vinyl alcohol)/sodium alginate hybrid scaffolds. Int J Biol Macromol 95:962–973. https://doi.org/10.1016/j.ijbiomac.2016.10.085

Zhong C, Wang C, Wang F, Jia H, Wei P, Zhao Y (2016) Application of tetra-n-methylammonium hydroxide on cellulose dissolution and isolation from sugarcane bagasse. Carbohydr Polym 136:979–987. https://doi.org/10.1016/j.carbpol.2015.10.001

Hou X, Xue Z, **a Y (2018) Preparation of a novel agar/sodium alginate fire-retardancy film. Mate Lett 233:274–277. https://doi.org/10.1016/j.matlet.2018.09.026

Tanpichai S, Oksman K (2018) Crosslinked poly (vinyl alcohol) composite films with cellulose nanocrystals: mechanical and thermal properties. J Appl Polym Sci 135:45710. https://doi.org/10.1002/app.45710

Wu N, Niu F, Lang W, **a M (2019) Highly efficient flame-retardant and low-smoke-toxicity poly(vinyl alcohol)/alginate/montmorillonite composite aerogels by two-step crosslinking strategy. Carbohydr Polym 221:221–230. https://doi.org/10.1016/j.carbpol.2019.06.007

Ma X, Wang C, Yuan W, **e X, Song Y (2021) Highly adhesive, conductive, and self-healing hydrogel with triple cross-linking inspired by mussel and DNA for wound adhesion and human motion sensing. ACS Appl Polym Mater. https://doi.org/10.1021/acsapm.1c01288

Dai L, Cheng T, Duan C, Zhao W, Zhang W, Zou X, Aspler J, Ni Y (2019) 3D printing using plant-derived cellulose and its derivatives: a review. Carbohydr Polym 203:71–86. https://doi.org/10.1016/j.carbpol.2018.09.027

Atay HY, Celik E (2016) Flame retardant properties of boric acid and antimony oxide accompanying with huntite and hydromagnesite in the polymer composites. Polym Polym Compos 24(6):419–428. https://doi.org/10.1177/096739111602400605

Demirel M, Pamuk V, Dilsiz N (2010) Investigation of flame retardancy and physical-mechanical properties of zinc borate/boric acid polyester composites. J Appl Polym Sci 115(5):2550–2555. https://doi.org/10.1002/app.31210

Wang ZH, Zhang AN, Liu BW, Wang XL, Zhao HB, Wang YZ (2022) Durable flame-retardant cotton fabrics with tannic acid complexed by various metal ions. Polym Degrad Stabil 201:109997. https://doi.org/10.1016/j.polymdegradstab.2022.109997

Zhao W, Kundu CK, Li Z, Li X, Zhang Z (2021) Flame retardant treatments for polypropylene: strategies and recent advances. Compos A 145:106382. https://doi.org/10.1016/j.compositesa.2021.106382

Cheng Z, Yu H, Li L, Li Y, Zhang XL, Jiang H (2009) Preparation of the boron nitride fibers by chemical reaction. Adv Mater 66:191–193. https://doi.org/10.4028/www.scientific.net/AMR.66.191

Deepa B, Abraham E, Pothan L, Cordeiro N, Faria M, Thomas S (2016) Biodegradable nanocomposite films based on sodium alginate and cellulose nanofibrils. Materials 9(1):50. https://doi.org/10.3390/ma9010050

Abouzeid RE, Khiari R, Salama A, Diab M, Beneventi D, Dufresne A (2016) In situ mineralization of nano-hydroxyapatite on bifunctional cellulose nanofiber/polyvinyl alcohol/sodium alginate hydrogel using 3D printing. Int J Biol Macromol 160:538–547. https://doi.org/10.1016/j.ijbiomac.2020.05.181

Jiang S, Zhang M, Li M, Zhu J, Ge A, Liu L, Yu J (2021) Cellulose-based composite thermal-insulating foams toward eco-friendly, flexible and flame-retardant. Carbohydr Polym 273:118544. https://doi.org/10.1016/j.carbpol.2021.118544

Ullah S, Ahmad F, Shariff AM, Bustam MA, Gonfa G, Gillani QF (2017) Effects of ammonium polyphosphate and boric acid on the thermal degradation of an intumescent fire-retardant coating. Prog Org Coat 109:70–82. https://doi.org/10.1016/j.porgcoat.2017.04.017

Llorens-Gamez M, Serrano-Aroca A (2018) Low-cost advanced hydrogels of calcium alginate/carbon nanofibers with enhanced water diffusion and compression properties. Polymers 10(4):405. https://doi.org/10.3390/polym10040405

Acknowledgements

This work was supported by the Foundation of Guangxi Key Laboratory of Clean Pulp & Papermaking and Pollution Control, College of Light Industry and Food Engineering, Guangxi University (No. 2021KF30) and the Key Research & Development Project of Shaanxi Province (No. 2019GY-195).

Funding

Open fund of Guangxi Key Laboratory of Clean Pulp & Papermaking and Pollution Control, College of Light Industry and Food Engineering, Guangxi University (No. 2021KF30), Key Research & Development Project of Shaanxi Province (No. 2019GY-195).

Author information

Authors and Affiliations

Contributions

All authors contributed to the study conception and design. XY: Responsible for the idea, methodology, supervision, writing original draft. WD: investigation, data curation, writing original draft. ZZ: writing—review and editing, formal analysis. YX: visualization, revise the original manuscript. HJ: characterization analysis, data curation. ZW: funding acquisition, review and editing. All authors commented on its previous versions, and all authors read and approved the final manuscript.

Corresponding authors

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Consent for Publication

All authors agreed to publish.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Yue, X., Deng, W., Zhou, Z. et al. Reinforced and Flame Retarded Cellulose Nanofibril/Sodium Alginate Compound Aerogel Fabricated via Boric Acid/Ca2+ Double Cross-Linking. J Polym Environ 31, 1038–1050 (2023). https://doi.org/10.1007/s10924-022-02673-1

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10924-022-02673-1