Abstract

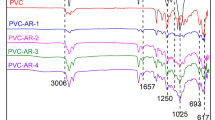

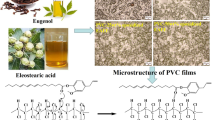

In this study, isosorbide-based eco-friendly and effective plasticizers were synthesized and characterized. Isosorbide esterification was conducted using fatty acids with different alkyl-chain lengths; the optimal degree of isosorbide esterification was obtained after 6 h reaction at 220 °C with a short alkyl-chain fatty acid in the presence of the catalyst Ti(OBu)4. Isosorbide-based plasticizers of C12 or more alkyl-chain lengths exhibited low compatibility and did not form PVC sheets. An esterified isosorbide with long alkyl-chain length was epoxidized to enhance its plasticizing properties and enable low-cost production; the high epoxidation degree (91%) indicated efficient epoxidation by formic acid and hydrogen peroxide. The synthesized plasticizers, according to the alkyl-chain length, were used to fabricate PVC sheets; subsequently, their mechanical and thermal properties were analyzed. As the alkyl-chain length of the synthesized plasticizer increased, the tensile strength and modulus increased, while the elongation decreased. Furthermore, as the plasticizer content increased, the tensile strength and elongation decreased, while the plasticization efficiency increased. As the alkyl-chain length of the plasticizer increased, the molecular weight increased and the smaller molecules generated more free volume in the PVC chain. The thermal stability of the synthesized isosorbide-based plasticizers improved on increasing their alkyl-chain length, and was higher than that of a commercial plasticizer. Thus, the plasticizers synthesized in this study, particularly isosorbide di epoxidized oleate, could be used as eco-friendly and effective plasticizers for practical PVC applications.

Similar content being viewed by others

References

Dong T, Li D, Li Y, Han W, Zhang L, **e G, Sunarso J, Liu S (2019) Design and synthesis of polyol ester-based zinc metal alkoxides as a bi-functional thermal stabilizer for poly(vinyl chloride). Polym Degrad Stabil 159:125–132. https://doi.org/10.1016/j.polymdegradstab.2018.11.022

El-Shekeil YA, Sapuan SM, Jawaid M, Al-Shuja’a OM (2014) Influence of fiber content on mechanical, morphological and thermal properties of kenaf fibers reinforced poly(vinyl chloride)/thermoplastic polyurethane poly-blend composites. Mater Des 58:130–135. https://doi.org/10.1016/j.matdes.2014.01.047

Jia P, Zhang M, Hu L, Feng G, Bo C, Zhou Y (2015) Synthesis and application of environmental castor oil based polyol ester plasticizers for poly(vinyl chloride). ACS Sustainable Chem Eng 3:2187–2193. https://doi.org/10.1021/acssuschemeng.5b00449

Hosney H, Nadiem B, Ashour I, Mustafa I, El-Shibiny A (2018) Epoxidized vegetable oil and bio-based materials as PVC plasticizer. J Appl Polym Sci 135:46270. https://doi.org/10.1002/app.46270

Erythropel HC, Maric M, Cooper DG (2012) Designing green plasticizers: influence of molecular geometry on biodegradation and plasticization properties. Chemosphere 86:759–766. https://doi.org/10.1016/j.chemosphere.2011.10.054

Yang P, Yan J, Sun H, Fan H, Chen Y, Wang F, Shi B (2015) Novel environmentally sustainable cardanol-based plasticizer covalently bound to PVC via click chemistry: synthesis and properties. RSC Adv 5:16980–16985. https://doi.org/10.1039/C4RA15527K

Ekelund M, Azhdar B, Gedde UW (2010) Evaporative loss kinetics of di(2-ethylhexyl)phthalate (DEHP) from pristine DEHP and plasticized PVC. Polym Degrad Stabil 95:1789–1793. https://doi.org/10.1016/j.polymdegradstab.2010.05.007

Zou J, Su L, You F, Chen G, Guo S (2011) Dynamic rheological behavior and microcrystalline structure of dioctyl phthalate plasticized poly(vinyl chloride). J Appl Polym Sci 121:1725–1733. https://doi.org/10.1002/app.33765

Szarka G, Iván B (2013) Thermal properties, degradation and stability of poly(vinyl chloride) predegraded thermooxidatively in the presence of dioctyl phthalate plasticizer. J Macromol Sci A 50:208–214. https://doi.org/10.1080/10601325.2013.742804

Earls AO, Axford IP, Braybrook JH (2003) Gas chromatography–mass spectrometry determination of the migration of phthalate plasticisers from polyvinyl chloride toys and childcare articles. J Chromatogr A 983:237–246. https://doi.org/10.1016/s0021-9673(02)01736-3

Marcilla A, Garcia S, Garcia-Quesada JC (2008) Migrability of PVC plasticizers. Polym Test 27:221–233. https://doi.org/10.1016/j.polymertesting.2007.10.007

Earla A, Braslau R (2014) Covalently linked plasticizers: triazole analogues of phthalate plasticizers prepared by mild copper-free “click” reactions with azide-functionalized PVC. Macromol Rapid Commun 35:666–671. https://doi.org/10.1002/marc.201470020

Bocqué M, Voirin C, Lapinte V, Caillol S, Robin JJ (2016) Petro-based and bio-based plasticizers: chemical structures to plasticizing properties. J Polym Sci Part A: Polym Chem 54:11–33. https://doi.org/10.1002/pola.27917

Berg RW, Otero AD (2006) Analysis of adipate ester contents in poly(vinyl chloride) plastics by means of FT-Raman spectroscopy. Vib Spectrosc 42:222–225. https://doi.org/10.1016/j.vibspec.2006.05.031

Demir APT, Ulutan S (2013) Migration of phthalate and non-phthalate plasticizers out of plasticized PVC films into air. J Appl Polym Sci 128:1948–1961

Eckert E, Münch F, Göen T, Purbojo A, Müller J, Cesnjevar R (2016) Comparative study on the migration of di-2-ethylhexyl phthalate (DEHP) and tri-2-ethylhexyl trimellitate (TOTM) into blood from PVC tubing material of a heart-lung machine. Chemosphere 145:10–16. https://doi.org/10.1016/j.chemosphere.2015.11.067

Yang Y, Huang J, Zhang R, Zhu J (2017) Designing bio-based plasticizers: effect of alkyl chain length on plasticization properties of isosorbide diesters in PVC blends. Mater Des 126:29–36. https://doi.org/10.1016/j.matdes.2017.04.005

Chen J, Wang Y, Huang J, Li K, Nie X (2018) Synthesis of tung-oil-based triglycidyl ester plasticizer and its effects on poly(vinyl chloride) soft films. ACS Sustainable Chem Eng 6:642–651. https://doi.org/10.1021/acssuschemeng.7b02989

Jia P, Zhang M, Hu L, Liu C, Feng G, Yang X, Bo C, Zhou Y (2015) Development of a vegetable oil based plasticizer for preparing flame retardant poly (vinyl chloride) materials. RSC Adv 5:76392–76400. https://doi.org/10.1039/C5RA10509A

Stolp LJ, Gronlund PJ, Kodali DR (2019) Soybean oil fatty acid ester estolides as potential plasticizers. J Am Oil Chem Soc 96:727–738. https://doi.org/10.1002/aocs.12214

Suzuki AH, Botelho BG, Oliveira LS, Franca AS (2018) Sustainable synthesis of epoxidized waste cooking oil and its application as a plasticizer for polyvinyl chloride films. Eur Polym J 99:142–149. https://doi.org/10.1016/j.eurpolymj.2017.12.014

Mukherjee S, Ghosh M (2017) Studies on performance evaluation of a green plasticizer made byenzymatic esterification of furfuryl alcohol and castor oil fatty acid. Carbohydr Polym 157:1076–1084. https://doi.org/10.1016/j.carbpol.2016.10.075

Stolp LJ, Joseph E, Kodali DR (2019) Synthesis and evaluation of soy fatty acid ester estolides as bioplasticizers in poly(vinyl chloride). J Am Oil Chem Soc 96:1291–1302. https://doi.org/10.1002/aocs.12279

Patil SS, Jena HM (2021) Performance assessment of polyvinyl chloride films plasticized with Citrullus lanatus seed oil based novel plasticizer. Polym Test 101:107271. https://doi.org/10.1016/j.polymertesting.2021.107271

Briou B, Caillol S, Robin JJ, Lapinte V (2019) Non-endocrine disruptor effect for cardanol based plasticizer. Ind Crops Prod 130:1–8. https://doi.org/10.1016/j.indcrop.2018.12.060

Chen J, Liu Z, Li X, Liu P, Jiang J, Nie X (2016) Thermal behavior of epoxidized cardanol diethyl phosphate as novel renewable plasticizer for poly(vinyl chloride). Polym Degrad Stabil 126:58–64. https://doi.org/10.1016/j.polymdegradstab.2016.01.018

Cui C, Zhen Y, Qu J, Chen B, Tan T (2016) Synthesis of biosafety isosorbide dicaprylate ester plasticizer by lipase in solvent-free system and its sub-chronic toxicity in mice. RSC Adv 6:11959–11966. https://doi.org/10.1039/C5RA27537G

Greco A, Ferrari F, Maffezzoli A (2017) UV and thermal stability of soft PVC plasticized with cardanol derivatives. J Clean Prod 164:757–764. https://doi.org/10.1016/j.jclepro.2017.07.009

Yin B, Hakkarainen M (2011) Oligomeric isosorbide esters as alternative renewable resource plasticizers for PVC. J Appl Polym Sci 119:2400–2407. https://doi.org/10.1002/app.32913

Chen J, Liu Z, Jiang J, Nie X, Zhou Y, Murray RE (2015) A novel biobased plasticizer of epoxidized cardanol glycidyl ether: synthesis and application in soft poly (vinyl chloride) films. RSC Adv 5:56171–56180. https://doi.org/10.1039/C5RA07096A

Chen J, Liu Z, Wang K, Huang J, Li K, Nie X, Jiang J (2019) Epoxidized castor oil-based diglycidyl-phthalate plasticizer: synthesis and thermal stabilizing effects on poly (vinyl chloride). J Appl Polym Sci 136:47142. https://doi.org/10.1002/app.47142

Dussenne C, Delaunay T, Wiatz V, Wyart H, Suisse I, Sauthier M (2017) Synthesis of isosorbide: an overview of challenging reactions. Green Chem 19:5332–5344. https://doi.org/10.1039/C7GC01912B

Fenouillot F, Rousseau A, Colomines G, Saint-Loup R, Pascault JP (2010) Polymers from renewable 1,4:3,6-dianhydrohexitols (isosorbide, isomannide and isoidide): a review. Prog Polym Sci 35:578–622. https://doi.org/10.1016/j.progpolymsci.2009.10.001

Yang Y, **ong Z, Zhang L, Tang Z, Zhang R, Zhu J (2016) Isosorbide dioctoate as a “green” plasticizer for poly(lactic acid). Mater Des 91:262–268. https://doi.org/10.1016/j.matdes.2015.11.065

Pyeon HB, Park JE, Suh DH (2017) Non-phthalate plasticizer from camphor for flexible PVC with a wide range of available temperature. Polym Test 63:375–381. https://doi.org/10.1016/j.polymertesting.2017.08.029

Liu W, **e T, Qiu R (2017) Biobased thermosets prepared from rigid isosorbide and flexible soybean oil derivatives. ACS Sustain Chem Eng 5:774–783. https://doi.org/10.1021/acssuschemeng.6b02117

Ristić IS, Vukić N, Cakić S, Simendić V, Ristić O, Budinski-Simendić J (2012) Synthesis and characterisation of polyester based on isosorbide and butanedioic acid. J Polym Environ 20:519–527. https://doi.org/10.1007/s10924-012-0414-9

Yin B, Aminlashgari N, Yang X, Hakkarainen M (2014) Glucose esters as biobased PVC plasticizers. Eur Polym J 58:34–40. https://doi.org/10.1016/j.eurpolymj.2014.06.008

Yu D, Zhao J, Wang W, Qi J, Hu Y (2019) Mono-acrylated isosorbide as a bio-based monomer for the improvement of thermal and mechanical properties of poly(methyl methacrylate). RSC Adv 9:35532–35538. https://doi.org/10.1039/C9RA07548H

Sammaiah A, Padmaja KV, Prasad RBN (2014) Synthesis of epoxy jatropha oil and its evaluation for lubricant properties. J Oleo Sci 63:637–643. https://doi.org/10.5650/jos.ess13172

Jia P, Zheng M, Ma Y, Feng G, **a H, Hu L, Zhang M, Zhou Y (2019) Clean synthesis of epoxy plasticizer with quaternary ammonium phosphotungstate as catalyst from a byproduct of cashew nut processing. J Clean Prod 206:838–849. https://doi.org/10.1016/j.jclepro.2018.09.238

Zheng T, Wu Z, **e Q, Fang J, Hu Y, Lu M, **a F, Nie Y, Ji J (2018) Structural modification of waste cooking oil methyl esters as cleaner plasticizer to substitute toxic dioctyl phthalate. J Clean Prod 186:1021–1030. https://doi.org/10.1016/j.jclepro.2018.03.175

Bai Y, Wang J, Liu D, Zhao X (2020) Conversion of fatty acid methyl ester to epoxy plasticizer by auto-catalyzed in situ formation of performic acid: kinetic modeling and application of the model. J Clean Prod 259:120791. https://doi.org/10.1016/j.jclepro.2020.120791

Greco A, Ferrari F, Maffezzoli A (2016) Effect of the epoxidation yield of a cardanol derivative on the plasticization and durability of soft PVC. Polym Degrad Stabil 134:220–226. https://doi.org/10.1016/j.polymdegradstab.2016.10.010

Daniels PH (2009) A brief overview of theories of PVC plasticization and methods used to evaluate PVC-plasticizer interaction. J Vinyl Addit Technol 15:219–223. https://doi.org/10.1002/vnl.20211

Zhu H, Yang J, Wu M, Wu Q, Liu J, Zhang J (2021) Biobased plasticizers from tartaric acid: synthesis and effect of alkyl chain length on the properties of poly(vinyl chloride). ACS Omega 6:13161–13169. https://doi.org/10.1021/acsomega.1c01006

Lee S, Park MS, Shin J, Kim YW (2018) Effect of the individual and combined use of cardanol-based plasticizers and epoxidized soybean oil on the properties of PVC. Polym Degrad Stabil 147:1–11. https://doi.org/10.1016/j.polymdegradstab.2017.11.002

Kastner J, Cooper DG, Marić M, Dodd P, Yargeau V (2012) Aqueous leaching of di-2-ethylhexyl phthalate and “green” plasticizers from poly(vinyl chloride). Sci Total Environ 432:357–364. https://doi.org/10.1016/j.scitotenv.2012.06.014

Czogała J, Pankalla E, Turczyn R (2021) Recent attempts in the design of efficient PVC plasticizers with reduced migration. Materials 14:844. https://doi.org/10.3390/ma14040844

Feng G, Hu L, Ma Y, Jia P, Hu Y, Zhang M, Liu C, Zhou Y (2018) An efficient bio-based plasticizer for poly (vinyl chloride) from waste cooking oil and citric acid: synthesis and evaluation in PVC films. J Clean Prod 189:334–343. https://doi.org/10.1016/j.jclepro.2018.04.085

Tan J, Zhang S, Lu T, Li R, Zhong T, Zhu X (2019) Design and synthesis of ethoxylated esters derived from waste frying oil as anti-ultraviolet and efficient primary plasticizers for poly(vinyl chloride). J Clean Prod 229:1274–1282. https://doi.org/10.1016/j.jclepro.2019.04.395

Funding

This work was supported by the Nuclear R&D program of the Ministry of Science and ICT (Project No. 523410-23).

Author information

Authors and Affiliations

Contributions

Conceptualization: B-ML, JJ, and TSH; Methodology and investigation: B-ML, JJ, and TSH; Writing—original draft preparation: B-ML; Writing—review and editing, and supervision: H-JG and TSH. All authors have read and agreed to the published version of the manuscript.

Corresponding author

Ethics declarations

Conflict of interest

The authors have no relevant financial or non-financial interests to disclose.

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Lee, BM., Jung, J., Gwon, HJ. et al. Synthesis and Properties of Isosorbide-Based Eco-friendly Plasticizers for Poly(Vinyl Chloride). J Polym Environ 31, 1351–1358 (2023). https://doi.org/10.1007/s10924-022-02643-7

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10924-022-02643-7