Abstract

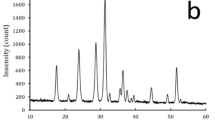

The medical sector needs medical devices that are biocompatible or bioabsorbable, and Poly Lactic Acid (PLA) satisfies that need. PLA is a thermoplastic polymer that degrades naturally and has good mechanical strength. In order to create anchors, screws, plates, pins, rods, and mesh for medical implants, polylactic acid, which is harmless, can be broken down into lactic acid. The primary objective of this work is to characterize the mechanical properties and material properties of polymer composite materials reinforced with hydroxyapatite (HAp), zeolite, magnesium, and zinc particulates for biomedical implant applications. Using an injection moulding process, the composite samples were created. Mechanical qualities such as tensile, compression, flexural strength, and shore D hardness were examined in accordance with American Society for Testing and Materials (ASTM) standards. The maximum tensile, compressive, and flexural strength were found to be 39.23 MPa, 36.80 MPa, and 68.25 MPa, respectively, for 65 wt.% PLA + 35 wt.% HAp + 5% wt.% Zeolite polymer composites were observed, and a maximum Shore D hardness of 79.8 SHN was found. Further, material characterizations were carried out for this composite material. The morphological characterization using Field Emission Scanning Electron Microscopy (FESEM) and Energy Dispersive X-ray (EDAX) analysis was used to analyze the surface morphology and confirm the various proportions of elements in the PLA composites. Fourier-transform infrared spectroscopy (FT IR) was used to confirm the different functional groups. Thermogravimetric analysis (TGA) and derivative thermogravimetric (DTG) analysis were used to study the thermal properties of polymer composites. The results show that the fabricated polymer composites could have better mechanical strength and be suitable for medical implant applications.

Similar content being viewed by others

Data Availability

Not applicable.

References

R.S. Reis Pedro et al., Development of biocomposite materials from a biodegradable polymer and bio-hydroxyapatite derived from eggshells for biomedical applications, in Characterization of minerals, metals, and materials. (Springer, Cham, 2019), pp.571–581

R. Nishant, R. Singh, I.P.S. Ahuja, Material processing of PLA-HAp-CS-based thermoplastic composite through fused deposition modeling for biomedical applications, in Biomanufacturing. (Springer, Cham, 2019), pp.123–136

S. Singh et al., 3D printed biodegradable composites: an insight into mechanical properties of PLA/chitosan scaffold. Polym. Test. 89, 106722 (2020)

R. Singh et al., Investigations for tensile, compressive and morphological properties of 3D printed functional prototypes of PLA-PEKK-HAp-CS. J. Thermoplast. Compos. Mater 34(10), 1408–1427 (2021)

S. Hu et al., Study on the mechanical and thermal properties of polylactic acid/hydroxyapatite@ polydopamine composite nanofibers for tissue engineering. J. Appl. Polym. Sci. 137(36), 49077 (2020)

S. Dabees et al., Experimental design of Al2O3/MWCNT/HDPE hybrid nanocomposites for hip joint replacement. Bioengineered 11(1), 679–692 (2020)

M. Hajibeygi, S. Shafiei-Navid, Design and preparation of poly (lactic acid) hydroxyapatite nanocomposites reinforced with phosphorus-based organic additive: thermal, combustion, and mechanical properties studies. Polym. Adv. Technol. 30(9), 2233–2249 (2019)

J. Chakravarty et al., Mechanical and biological properties of chitin/polylactide (PLA)/hydroxyapatite (HAP) composites cast using ionic liquid solutions. Int. J. Biol. Macromol. 151, 1213–1223 (2020)

Z. Huang et al., Incorporating nanoplate-like hydroxyapatite into polylactide for biomimetic nanocomposites via direct melt intercalation. Compos. Sci. Technol. 185, 107903 (2020)

G.S. Medeiros et al., Polymer nanocomposites based on poly (ε-caprolactone), hydroxyapatite and graphene oxide. J. Polym. Environ. 28(1), 331–342 (2020)

E. Pietrzykowska et al., Preparation of a ceramic matrix composite made of hydroxyapatite nanoparticles and polylactic acid by consolidation of composite granules. Nanomaterials 10(6), 1060 (2020)

H.-M. Ng et al., Effect of electron beam irradiation sterilization on biomedical polylactic acid composite filled with Scomberomorus guttatus-derived hydroxyapatite. Compos. Part B: Eng. 176, 107273 (2019)

N. Ranjan, R. Singh, I.P.S. Ahuja, Investigations on joining of orthopaedic scaffold with rapid tooling. Proc. Inst. Mechan. Eng. Part H: J. Eng. Med. 233(7), 754–760 (2019)

M. Wolff et al., Magnesium powder injection moulding for biomedical application. Powder Metall. 57(5), 331–340 (2014)

A. Royer et al., Development and characterisation of a biosourced feedstock of superalloy in metal injection moulding process. Powder Metall. 60(2), 105–111 (2017)

C.B. Ayyanar et al., Design, fabrication, and characterization of natural fillers loaded HDPE composites for domestic applications. Polym. Compos. 43, 5168 (2022)

R. Maertens et al., Study of material homogeneity in the long fiber thermoset injection molding process by image texture analysis. Adv. Manuf.: Polym. Compos. Sci. 8(1), 22–32 (2022)

S. Rajan et al., In-vitro cytotoxicity of zinc oxide, graphene oxide, and calcium carbonate nano particulates reinforced high-density polyethylene composite. J. Mater. Res. Technol. 18, 921–930 (2022)

B.A. Chinnappan et al., Fabrication, characterization and in vitro assessment of laevistrombus canarium-derived hydroxyapatite particulate-filled polymer composite for implant applications. Polymers 14(5), 872 (2022)

K. Ahmed et al., Effect of de-sizing on the structural and mechanical properties of carbon fiber reinforced polypropylene composites molded by the novel direct fiber feeding injection molding technology. J. Thermoplast. Compos. Mater. (2022). https://doi.org/10.1177/08927057221077872

C.B. Ayyanar et al., Development and characterization of Hevea brasiliensis particulates filled polyethylene composites. Polym. Compos. 43(4), 2047–2054 (2022)

E. Jeong et al., Innovative injection molding process for the fabrication of woven fabric reinforced thermoplastic composites. Polymers 14(8), 1577 (2022)

H. Yang et al., Cell morphologies, mechanical properties, and fiber orientation of glass fiber-reinforced polyamide composites: influence of subcritical gas-laden pellet injection molding foaming technology. Phys. Fluids 34(1), 013101 (2022)

C.B. Ayyanar et al., Characterization of Syzygium cumini particulates filled E-glass fiber-reinforced epoxy composites. Polym. Compos. 42(12), 6298–6309 (2021)

K. Chai et al., Effect of nano TiO2 on the cellular structure and mechanical properties of wood flour/polypropylene composite foams via mold-opening foam injection molding. J. Appl. Polym. Sci. 139, e52603 (2022)

A.A. Moorthy et al., In vitro cytotoxicity examination of the seashell and fish scale substances embedded with high degree of compactness in polyethylene composite. J. Eng. Res. (2021). https://doi.org/10.36909/jer.ICMMM.12431

N.A.T.M. Shahruk, F. Pahlevani, V. Sahajwalla, Study on the direct transformation of milk bottle and wood into wood-plastic composite through injection molding. J. Compos. Sci. 6(8), 230 (2022)

C.B. Ayyanar et al., Characterization and in vitro cytotoxicity evaluation of fish scale and seashell derived nano-hydroxyapatite high-density polyethylene composite. Polym. Polym. Compos. 29(9), 1534–1542 (2021)

M. Subramanian, A. Vallavi, M. Thanigachalam, Mechanical performances, in-vitro antibacterial study and bone stress prediction of ceramic particulates filled polyether ether ketone nanocomposites for medical applications. J. Polym. Res. 29(8), 1–18 (2022)

M. Thanigachalam, A.V.M. Subramanian, Evaluation of PEEK-TiO2-SiO2 nanocomposite as biomedical implants with regard to in-vitro biocompatibility and material characterization. J. Biomater. Sci. Polym. Ed. 33(6), 727–746 (2022)

C.K. Kailasanathan et al., Polyoxymethylene/talc composite: investigation of warpage, mechanical and thermal properties for thin walled-injection molding applications. J. Appl. Polym. Sci. 139(10), 51762 (2022)

T. Mugilan, M.S.A. Vallavi, D. Sugumar, Materialistic characterization, thermal properties, and cytocompatibility investigations on acrylic acid-functionalized nSiO2-reinforced PEEK polymeric nanocomposite. Colloid Polym. Sci. 300, 1155 (2022)

K. Buyuksoy-Fekraoui et al., Characterization of optimized ternary PLA/PHB/organoclay composites processed through fused filament fabrication and injection molding. Materials 15(9), 3398 (2022)

A. Borkar et al., A comparison of mechanical properties of recycled high-density polyethylene/waste carbon fiber via injection molding and 3D printing. Polym. Compos. 43(4), 2408–2418 (2022)

Acknowledgement

This research was funded by King Mongkut’s University of Technology North Bangkok with Contract no. KMUTNB-66-KNOW-13.

Funding

Not applicable.

Author information

Authors and Affiliations

Contributions

All authors are equally contributed to Conceptualization, Methodology, Writing—original draft, Writing—review & editing.

Corresponding author

Ethics declarations

Competing Interests

The authors declare no competing interests.

Ethical Approval

The authors hereby state that the present work is following the ethical standards.

Consent to Participate

Not applicable.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Ayyanar, C.B., Marimuthu, K., Sridhar, N. et al. Mechanical and Materialistic Characterization of Poly Lactic Acid/Zeolite/Hydroxyapatite Composites. J Inorg Organomet Polym 33, 2743–2751 (2023). https://doi.org/10.1007/s10904-023-02647-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10904-023-02647-3