Abstract

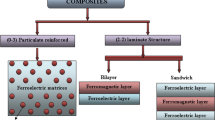

The multiferroic magnetoelectric 2–2 laminated composite systems with BaTiO3 and NiFe2O4 as the ferroelectric and ferrimagnetic phases were successfully fabricated by co-firing technique. For this phase, pure BaTiO3 and NiFe2O4 were successfully synthesized by sol–gel and polyol method, respectively. The structural, microstructural, multiferroic and magnetoelectric coupling properties of phase pure and co-fired systems were investigated using X-ray diffraction, HR-TEM, SEM–EDX, P–E Loop, VSM and magnetoelectric coupling analysis. The multiferroic and magnetoelectric coupling properties of the laminated systems were compared with the mixed system having similar weight percentage of BaTiO3 and NiFe2O4. The fabricated composite systems show good multiferroic and magnetoelectric properties. Compared to mixed composite systems, the laminated structure has an enhanced magnetoelectric (ME) coupling of 6.42 mV/cm.Oe. This variation in ME coupling is attributed to the low leakage current effects in the laminated systems. The ME coupling in the laminates varies with the nature and number of layers. For laminated composite systems, the ME coupling coefficient is found to increase from 6.42 mV/cm.Oe to 10.48 mV/cm.Oe with increase in the number of layers.

Similar content being viewed by others

Data availability

Data will be made available on reasonable request.

References

M.M. Vopson, Crit. Rev. Solid State Mater. Sci. 40, 223 (2015). https://doi.org/10.1080/10408436.2014.992584

G. Schileo, Prog. Solid State Chem. 41, 87 (2013). https://doi.org/10.1016/j.progsolidstchem.2013.09.001

D.K. Pradhan, S. Kumari, P.D. Rack, Nanomaterials (2020). https://doi.org/10.3390/nano10102072

K. Sakthipandi, V. Rajendran, T. Jayakumar, B. Raj, P. Kulandivelu, J. Alloys Compd. 509, 3457 (2011)

K. Sakthipandi, V. Rajendran, T. Jayakumar, Mater. Res. Bull. 48, 1651 (2013)

R.R. Kanna, K. Sakthipandi, A.S. Kumar, N.R. Dhineshbabu, S.M.S.M.A. Maraikkayar, A.S. Afroze, R.B. Jotania, M. Sivabharathy, Ceram. Int. 46, 13695 (2020)

C.W. Nan, M.I. Bichurin, S. Dong, D. Viehland, G. Srinivasan, J. Appl. Phys. (2008). https://doi.org/10.1063/1.2836410

Y. Wang, J. Hu, Y. Lin, C. Nan, NPG Asia Mater. 2, 61 (2010). https://doi.org/10.1038/asiamat.2010.32

P. Barone, S. Picozzi, Comptes Rendus Phys. 1, 1 (2015). https://doi.org/10.1016/j.crhy.2015.01.009

C. Pascual-Gonzalez, G. Schileo, A. Feteira, Single-Phase Composite and Laminate Multiferroics (Elsevier, 2018)

A. Ahlawat, S. Satapathy, P. Deshmukh, M.M. Shirolkar, A.K. Sinha, A.K. Karnal, Appl. Phys. Lett. (2017). https://doi.org/10.1063/1.5008443

J.P. Praveen, V.R. Monaji, E. Chandrakala, S. Indla, V. Subramanian, D. Das, J. Alloys Compd. 750, 392–400 (2018). https://doi.org/10.1016/j.jallcom.2018.04.026

J. Ma, J. Hu, Z. Li, C.W. Nan, Adv. Mater. 23, 1062 (2011). https://doi.org/10.1002/adma.201003636

A. Srinivas, R.V. Krishnaiah, V.L. Niranjani, S.V. Kamat, T. Karthik, S. Asthana, Ceram. Int. 41, 1980 (2015). https://doi.org/10.1016/j.ceramint.2014.08.127

R. Sharma, R.P. Tandon, J. Mater. Sci. Mater. Electron. 26, 5287 (2015). https://doi.org/10.1007/s10854-015-3065-5

G. Srinivasan, E.T. Rasmussen, J. Gallegos, R. Srinivasan, Y.I. Bokhan, V.M. Laletin, Phys. Rev. B—Condens. Matter Mater. Phys. (2001). https://doi.org/10.1103/PhysRevB.64.214408

R.A. Islam, S. Priya, Appl. Phys. Lett. 89, 109 (2006). https://doi.org/10.1063/1.23611180

Y. Liu, G. Xu, Y. **e, H. Lv, C. Huang, Y. Chen, Z. Tong, J. Shi, R. **ong, Ceram. Int. 44, 9649 (2018). https://doi.org/10.1016/j.ceramint.2018.02.192

H. Yang, G. Zhang, Y. Lin, J. Alloys Compd. 644, 390 (2015). https://doi.org/10.1016/j.jalcom.2015.05.020

S. Dinesh Kumar, J. Magesh, V. Subramanian, J. Alloys Compd. 753, 595–600 (2018). https://doi.org/10.1016/j.jallcom.2018.04.275

Y. Wang, Y. Pu, Y. Shi, Y. Cui, J. Mater. Sci. Mater. Electron. 28, 11125 (2017). https://doi.org/10.1007/s10854-017-6899-1

P. Pravee J, V.R. Monaji, S.D. Kumar, V. Subramanian, D. Das, Ceram. Int. 44, 4298 (2018). https://doi.org/10.1016/j.ceramint.2017.12.018

D.S. Lam, N.N. Tung, D.D. Dung, B.X. Khuyen, V.D. Lam, T.D. Thanh, Mater. Res. Express (2022). https://doi.org/10.1088/2053-1591/ac7fe1

D. Padmapriya, D. Dhayanithi, M.T. Rahul, N. Kalarikkal, N.V. Giridharan, Appl. Phys. A Mater. Sci. Process. 127, 1 (2021). https://doi.org/10.1007/s00339-021-04431-x

R. Adnan Islam, S. Priya, Adv. Condens. Matter. Phys. (2012). https://doi.org/10.1155/2012/320612

K.P.C. Dhanyaprabha, B. Jacob, M. Mohan, I.A. Al-Omari, S.H. Al-Harthi, M.T.Z. Myint, H. Thomas, Phys. Status Solidi Appl. Mater. Sci. 218, 1 (2021). https://doi.org/10.1002/pssa.202100193

F.D. Cortés-Vega, C. Montero-Tavera, J.M. Yañez-Limón, Bol.La Soc. Esp. Ceram. y Vidr. 62, 284–291 (2023). https://doi.org/10.1016/j.bsecv.2022.03.002

V.R. Mudinepalli, L. Feng, W.C. Lin, B.S. Murty, J. Adv. Ceram. 4, 46 (2015). https://doi.org/10.1007/s40145-015-0130-8

R. Revathy, N. Kalarikkal, M.R. Varma, K.P. Surendran, J. Alloys Compd. 889, 161667 (2022). https://doi.org/10.1016/j.jallcom.2021.161667

M. Muneeswaran, A. Akbari-Fakhrabadi, M.A. Gracia-Pinilla, J.C. Denardin, N.V. Giridharan, Sci. Rep. 11, 1 (2021). https://doi.org/10.1038/s41598-021-81867-4

N. Ponpandian, A. Narayanasamy, C.N. Chinnasamy, N. Sivakumar, J.M. Greneche, K. Chattopadhyay, K. Shinoda, B. Jeyadevan, K. Tohji, Appl. Phys. Lett. 86, 1 (2005). https://doi.org/10.1063/1.1925755

L.P. Curecheriu, M.T. Buscaglia, V. Buscaglia, L. Mitoseriu, P. Postolache, A. Ianculescu, P. Nanni, J. Appl. Phys. (2010). https://doi.org/10.1063/1.3340844

W. Chen, Z.H. Wang, W. Zhu, O.K. Tan, J. Phys. D Appl. Phys. (2009). https://doi.org/10.1088/0022-3727/42/7/075421

A. Khamkongkaeo, P. Jantaratana, C. Sirisathitkul, T. Yamwong, S. Maensiri, Trans. Nonferrous Met. Soc. China 21, 2438 (2011). https://doi.org/10.1016/S1003-6326(11)61033-9

F. Saffari, P. Kameli, M. Rahimi, H. Ahmadvand, H. Salamati, Ceram. Int. 41, 7352 (2015). https://doi.org/10.1016/j.ceramint.2015.02.038

S. Sharma, S. Thakur, J. Shah, R.K. Kotnala, N.S. Negi, J. Mater. Sci. Mater. Electron. 32, 6570 (2021). https://doi.org/10.1007/s10854-021-05373-z

S. Sharma, H. Sharma, S. Thakur, J. Shah, R.K. Kotnala, N.S. Negi, J. Magn. Magn. Mater. 538, 168243 (2021). https://doi.org/10.1016/j.jmmm.2021.168243

R.M. Thankachan, B. Raneesh, A. Mayeen, S. Karthika, S. Vivek, S.S. Nair, S. Thomas, N. Kalarikkal, J. Alloys Compd. 731, 288 (2018). https://doi.org/10.1016/j.jallcom.2017.09.309

K.C. Dhanyaprabha, B. Jacob, M. Mohan, I.A. Al-omari, S.H. Al-harthi, M.T.Z. Myint, H. Thomas, Mater. Sci. Eng. B 298, 116859 (2023)

M.M. Devi, A. Anand, R.K. Veena, K. Nandakumar, S. Sagar, J. Mater. Sci. Mater. Electron. 32, 27073 (2021). https://doi.org/10.1007/s10854-021-07078-9

Acknowledgements

The authors thank St. Thomas College Thrissur, CLIF Kariavattom, and IIT Roorkee, for providing XRD, SEM-EDX, and VSM measurement facilities. The authors are grateful to Dr. Nandakumar Kalarikkal, Rahul M. T. and Anu A. S. of IIUCNN, MG University Kottayam for ME measurement and HR-TEM measurement. Author K. C. Dhanyaprabha wishes to acknowledge Department of Science and Technology, India for the financial support under Women Scientist Scheme-A (SR/WOS-A/PM-65/2017). Hysen Thomas acknowledges financial support received from Kerala State Council for Science, Technology and Environment under Science Research Scheme (KSCSTE/1483/2019).

Funding

Funding was provided by Department of Science and Technology under Women Scientist Scheme A (WOS-A [SR/WOS-A/PM-65/2017]) and Kerala State Council for Science, Technology and Environment under Science Research Scheme (KSCSTE/1483/2019).

Author information

Authors and Affiliations

Contributions

All authors contributed and participated in conception, design, analysis and interpretation, also the final manuscript was approved by them.

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Dhanyaprabha, K.C., Jacob, B., Mohan, M. et al. Fabrication of BaTiO3/NiFe2O4 multiferroic laminated composite systems for magnetoelectric applications. J Mater Sci: Mater Electron 35, 1117 (2024). https://doi.org/10.1007/s10854-024-12856-2

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s10854-024-12856-2