Abstract

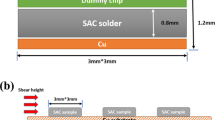

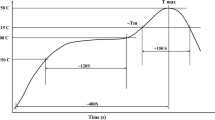

Cu/Sn-3.0Ag-0.5Cu-xBi/Cu solder lap joints were prepared using Sn-3.0Ag-0.5Cu (SAC305) solder paste doped with 0, 1 wt%, 3 wt% and 7 wt% Bi powder, respectively. The different samples were immersed in 3.5 wt% NaCl solution for a maximum of 28 days, and the corrosion products were SnO, SnO2 and Sn3O(OH)2Cl2. The samples were observed and tested at different periods of the study, and the shear strength, corrosion morphology, XRD phase diagrams and weight changes of the joints were compared with those of the joints with different do** concentrations. The results showed that the shear strength of SAC305 solder joints increased and then decreased with the increase of Bi do** concentration. Although the 7 wt% Bi doped lap joint had the lowest shear strength and was still the lowest at the end of the 28 day immersion corrosion tests, the decrease in shear strength with increasing immersion time was the slowest compared to the joints with other Bi do** concentrations. The results suggest that high concentrations of Bi do** in SAC305 solder joints have a corrosion-blocking effect.

Similar content being viewed by others

Data availability

The research data cannot be shared at this time, because it is part of the current research work.

References

L.N. Ramanathan, J.W. Jang, J.K. Lin et al., Solid-state annealing behavior of two high-Pb solders, 95Pb5Sn and 90Pb10Sn, on Cu under bump metallurgy. J. Electron. Mater. 34, L43–L46 (2005)

X. Bi, X. Hu, Q. Li, Effect of Co addition into Ni film on shear strength of solder/Ni/Cu system: experimental and theoretical investigations. Mater. Sci. Eng. A 788, 139589 (2020)

L.C. Tsao, Evolution of nano-Ag3Sn particle formation on Cu–Sn intermetallic compounds of Sn3.5Ag0.5Cu composite solder/Cu during soldering. J. Alloys Compd. 509(5), 2326–2333 (2011)

M. Turner, D. Callaghan, Will IT in the UK become greener in 2006?—the impact of the new UK regulations on the use of hazardous substances in electrical and electronic equipment. Comput. Law Secur. Rev. 22(2), 172–175 (2006)

Z.J. Yang, S.M. Yang, H.S. Yu et al., IMC and creep behavior in lead-free solder joints of Sn-Ag and Sn-Ag-Cu alloy system by SP method. Int. J. Automot. Technol. 15, 1137–1142 (2014)

J.G. Lee, K.N. Subramanian, Effect of dwell times on thermomechanical fatigue behavior of Sn-Ag-based solder joints. J. Electron. Mater. 32, 523–530 (2003)

Y. Wang, J. Han, L. Ma et al., Electromigration behaviors of Cu reinforced Sn-3.5 Ag composite solder joints. J. Electron. Mater. 45, 6095–6101 (2016)

T. Takahashi, S. Komatsu, H. Nishikawa et al., Improvement of high-temperature performance of Zn-Sn solder joint. J. Electron. Mater. 39, 1241–1247 (2010)

W. Wang, M. Osterman, D. Das et al., Solder joint reliability of SnAgCu solder refinished components under temperature cycling test. IEEE Trans. Compon. Packag. Manufact. Technol. 1(5), 798–808 (2011)

J.W. Yoon, S.B. Jung, Reliability studies of Sn–9Zn/Cu solder joints with aging treatment. J. Alloy. Compd. 407(1–2), 141–149 (2006)

X. Hu, T. Xu, L.M. Keer et al., Microstructure evolution and shear fracture behavior of aged Sn3Ag0.5Cu/Cu solder joints. Mater. Sci. Eng. A 673, 167–177 (2016)

X. Hu, T. Xu, L.M. Keer et al., Shear strength and fracture behavior of reflowed Sn3.0Ag0.5Cu/Cu solder joints under various strain rates. J. Alloys Compd. 690, 720–729 (2017)

F. Rosalbino, G. Zanicchi, R. Carlini et al., Electrochemical corrosion behaviour of Sn–Ag–Cu (SAC) eutectic alloy in a chloride containing environment. Mater. Corros. 63(6), 492–496 (2012)

M. Wang, C. Qiao, X. Jiang et al., Microstructure induced galvanic corrosion evolution of SAC305 solder alloys in simulated marine atmosphere. J. Mater. Sci. Technol. 51, 40–53 (2020)

P.L. Liu, J.K. Shang, Interfacial embrittlement by bismuth segregation in copper/tin-bismuth Pb-free solder interconnect. J. Mater. Res. 16(6), 1651–1659 (2001)

A. Yakymovych, P. Švec, L. Orovcik et al., Nanocomposite SAC solders: the effect of adding Ni and Ni-Sn nanoparticles on morphology and mechanical properties of Sn-3.0 Ag-0.5 Cu solders. J. Electron. Mater. 47, 117–123 (2018)

H. Wang, X. Hu, X. Jiang, Effects of Ni modified MWCNTs on the microstructural evolution and shear strength of Sn-3.0 Ag-0.5 Cu composite solder joints. Mater Charact 163, 110287 (2020)

D. Giuranno, S. Delsante, G. Borzone et al., Effects of Sb addition on the properties of Sn-Ag-Cu/(Cu, Ni) solder systems. J. Alloy. Compd. 689, 918–930 (2016)

M. Hasnine, M.J. Bozack, Effects of Ga additives on the thermal and wetting performance of Sn-07 Cu solder. J. Electron. Mater. 48, 3970–3978 (2019)

Z. Zhang, X. Hu, X. Jiang et al., Influences of mono-Ni (P) and dual-Cu/Ni (P) plating on the interfacial microstructure evolution of solder joints. Metall. and Mater. Trans. A. 50, 480–492 (2019)

A.A. El-Daly, A.M. El-Taher, S. Gouda, Development of new multicomponent Sn–Ag–Cu–Bi lead-free solders for low-cost commercial electronic assembly. J. Alloy. Compd. 627, 268–275 (2015)

Z. Dong, K. You, H. Yuan et al., Machine learning assisted design of high-strength Sn-3.8 Ag-0.7 Cu alloys with the co-additions of Bi and In. Mater. Sci. Eng. A 861, 144257 (2022)

H.Y. Zahran, A.S. Mahmoud, A.F. Abd El-Rehim, Effect of Bi content on the microstructure and mechanical performance of Sn-1Ag-0.5 Cu solder alloy. Crystals 11(3), 314 (2021)

C. Pu, J. Qiu, C. Li et al., Effects of Bi addition on the solderability and mechanical properties of Sn-Zn-Cu lead-free solder. J. Electron. Mater. 51(9), 4952–4963 (2022)

N.K. Liyana, M.A. Fazal, A. Haseeb et al., Effect of Zn incorporation on the electrochemical corrosion properties of SAC105 solder alloys. J. Mater. Sci. Mater. Electron. 30, 7415–7422 (2019)

M. Said, M.F.M. Nazeri, N.M. Sharif et al., Corrosion properties of Cu/Sn–3.0 Ag–0.5 Cu/Cu solder butt joints fabricated by conventional reflow and microwave hybrid heating. Corr. Sci. 208, 110641 (2022)

A. Guédon-Gracia, H. Frémont, B. Plano et al., Effects of salt spray test on lead-free solder alloy. Microelectron. Reliab. 64, 242–247 (2016)

M. Fayeka, A. Haseeb, M.A. Fazal, Electrochemical corrosion behaviour of Pb-free SAC 105 and SAC 305 solder alloys: a comparative study. Sains Malays. 46(2), 295–302 (2017)

S.A. Belyakov, J.W. **an, K. Sweatman et al., Influence of bismuth on the solidification of Sn-0.7 Cu-0.05 Ni-xBi/Cu joints. J. Alloys Compd. 701, 321–334 (2017)

J.M. Juarez Jr., P. Snugovsky, E. Kosiba et al., Manufacturability and reliability screening of lower melting point, Pb-free alloys containing bismuth. J. Microelectron. Electron. Packag. 12(1), 1–28 (2015)

D. Li, P.P. Conway, C. Liu, Corrosion characterization of tin–lead and lead free solders in 35 wt% NaCl solution. Corr. Sci. 50(4), 995–1004 (2008)

U.S. Mohanty, K.L. Lin, Corrosion behavior of Pb-free Sn-1Ag-0.5 Cu-X Ni Solder Alloys in 3.5% NaCl solution. J. Electron. Mater. 42, 628–638 (2013)

M.H. Braga, J. Vizdal, A. Kroupa et al., The experimental study of the Bi–Sn, Bi–Zn and Bi–Sn–Zn systems. Calphad 31(4), 468–478 (2007)

S.D. Kapusta, N. Hackerman, Anodic passivation of tin in slightly alkaline solutions. Electrochim. Acta 25(12), 1625–1639 (1980)

P.E. Alvarez, S.B. Ribotta, M.E. Folquer et al., Potentiodynamic behaviour of tin in different buffer solutions. Corros. Sci. 44(1), 49–65 (2002)

H.S.E. El Abd, E.S. Gouda, N.A.A. Ghany, Effect of Al and Bi addition on the corrosion behaviour, hardness, and melting temperature of lead-free solder alloys. Microelectron. Reliab. 147, 115051 (2023)

J.A. Wu, A. Luktuke, N. Chawla, Surface precipitation and growth of bismuth particles in Sn-Ag-Cu-Bi solder joints. J. Electron. Mater. 52(2), 801–809 (2023)

Y. Chen, Z.C. Meng, L.Y. Gao et al., Effect of Bi addition on the shear strength and failure mechanism of low-Ag lead-free solder joints. J. Mater. Sci. Mater. Electron. 32, 2172–2186 (2021)

G.S. Duffó, S.B. Farina, F.M.S. Rodríguez, Corrosion behaviour of non-ferrous metals embedded in mortar. Constr. Build. Mater. 210, 548–554 (2019)

Funding

This work was supported by the National Natural Science Foundation of China (No. 52165047 and 52361009).

Author information

Authors and Affiliations

Contributions

LZ: Conceptualization, Methodology, Sample Preparation, Formal analysis, Investigation, Data curation, Writing—original draft, Visualization. WC: Investigation, Data curation, Visualization. XH: Methodology, Supervision, Resources, Writing—review and editing. ZZ: Methodology, Formal analysis, Data curation, Investigation. BC: Methodology, Formal analysis, Data curation. JW: Formal analysis, Data curation. ST: Sample Preparation, Methodology. XJ: Formal analysis, Investigation.

Corresponding authors

Ethics declarations

Competing interests

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Zhu, L., Chen, W., Hu, X. et al. Role of bismuth in the mechanical and corrosion properties of Cu/Sn-3.0Ag-0.5Cu/Cu solder lap joints. J Mater Sci: Mater Electron 35, 111 (2024). https://doi.org/10.1007/s10854-024-11942-9

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s10854-024-11942-9