Abstract

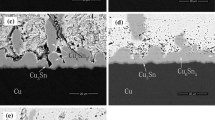

This paper aims to study the effect of soldering time and ultrasonic-assisted time to microstructures, chemical compositions and thickness of intermetallic compounds (IMCs) of three types solder joints after soldering at 290 °C. The Sn3.0Ag0.5Cu (SAC305) solder and three types substrate (pure Cu, Cu–50Co and Cu–50Fe) were selected. The results showed that the compounds formed at the SAC305/Cu solder joint were Cu3Sn and spherical Cu6Sn5, the stick-like (Co,Cu)Sn3 and finely needle-like (Cu,Co)6Sn5 were generated in SAC305/Cu–50Co, while the prismatic (Cu,Fe)6Sn5 and finely granular FeSn2 were produced in SAC305/Cu–50Fe. With the soldering time increased, the IMC overall thickness of all three types solder joints gradually increased. While ultrasound was used, the morphology of Cu6Sn5, (Co,Cu)Sn3 and (Cu,Fe)6Sn5 transformed into prismatic shapes, blocky and slender stick due to cavitation and acoustic flow effects. Moreover, with the application of ultrasound, the IMC thickness of SAC305/Cu and SAC305/Cu–50Co solder joints decreased first then started to up, while that of SAC305/Cu–50Fe solder joints decreased and then remained unchanged.

Similar content being viewed by others

Data availability

The research data cannot be shared at this time, because it is part of the current research work.

References

H.R. Kotadia, P.D. Howes, S.H. Mannan, A review: on the development of low melting temperature Pb-free solders[J]. Microelectron. Reliab. 54(6–7), 1253–1273 (2014)

Z. Chen, Y. Shi, Z. **a et al., Properties of lead-free solder SnAgCu containing minute amounts of rare earth[J]. J. Electron. Mater. 32, 235–243 (2003)

K. Zeng, K.N. Tu, Six cases of reliability study of Pb-free solder joints in electronic packaging technology[J]. Mater. Sci. Eng.: R: Rep. 38(2), 55–105 (2002)

H. Wang, X. Hu, X. Jiang, Effects of Ni modified MWCNTs on the microstructural evolution and shear strength of Sn–3.0Ag–0.5Cu composite solder joints[J]. Mater. Charact. 163, 110287 (2020)

G. Zeng, S. Liu, Q. Gu et al., Investigation on the solidification and phase transformation in Pb-free solders using in situ synchrotron radiography and diffraction: a review[J]. Acta Metall. Sin. (English Letters) 35(1), 49–66 (2022)

L.Y. Gao, H. Zhang, C.F. Li et al., Mechanism of improved electromigration reliability using Fe–Ni UBM in wafer level package[J]. J. Mater. Sci. Technol. 34(8), 1305–1314 (2018)

C. Wang, H. Shen, Effects of Ni addition on the interfacial reactions between Sn–Cu solders and ni substrate[J]. Intermetallics. 18(4), 616–622 (2010)

G. Humpston, Cobalt: a universal barrier metal for solderable under bump metallisations[J]. J. Mater. Sci.: Mater. Electron. 21, 584–588 (2010)

N. Lu, D. Yang, L. Li, Interfacial reaction between Sn–Ag–Cu solder and Co–P films with various microstructures[J]. Acta Mater. 61(12), 4581–4590 (2013)

Z. Zhang, X. Hu, X. Jiang et al., Influences of mono-Ni (P) and dual-Cu/Ni (P) plating on the interfacial microstructure evolution of solder joints[J]. Metall. Mater. Trans. A 50, 480–492 (2019)

L.Y. Gao, Z.Q. Liu, C.F. Li, Failure mechanisms of SAC/Fe–Ni solder joints during thermal cycling[J]. J. Electron. Mater. 46, 5338–5348 (2017)

X. Bi, X. Hu, Q. Li, Effect of Co addition into Ni film on shear strength of solder/Ni/Cu system: experimental and theoretical investigations[J]. Mater. Sci. Eng.: A 788, 139589 (2020)

L.Y. Gao, C.F. Li, P. Wan et al., A superior interfacial reliability of Fe–Ni UBM during high temperature storage[J]. J. Mater. Sci.: Mater. Electron. 28, 8537–8545 (2017)

T. An, F. Qin, Effects of the intermetallic compound microstructure on the tensile behavior of Sn3.0Ag0.5Cu/Cu solder joint under various strain rates[J]. Microelectron. Reliab. 54(5), 932–938 (2014)

L.Y. Gao, C.F. Li, P. Wan et al., The diffusion barrier effect of Fe–Ni UBM as compared to the commercial Cu UBM during high temperature storage[J]. J. Alloys Compd. 739, 632–642 (2018)

X. Hu, T. Xu, L.M. Keer et al., Microstructure evolution and shear fracture behavior of aged Sn3.0Ag0.5Cu/Cu solder joints[J]. Mater. Sci. Eng.: A 673, 167–177 (2016)

X. Hu, T. Xu, L.M. Keer et al., Shear strength and fracture behavior of reflowed Sn3.0Ag0.5Cu/Cu solder joints under various strain rates[J]. J. Alloys Compd. 690, 720–729 (2017)

J. Johansson, I. Belov, E. Johnson et al., Investigation on thermal fatigue of SnAgCu, Sn100C, and SnPbAg solder joints in varying temperature environments[J]. Microelectron. Reliab. 54(11), 2523–2535 (2014)

Y. Qiao, H. Ma, F. Yu et al., Quasi-in-situ observation on diffusion anisotropy dominated asymmetrical growth of Cu–Sn IMCs under temperature gradient[J]. Acta Mater. 217, 117168 (2021)

M.G. Cho, S.K. Seo, H.M. Lee, Wettability and interfacial reactions of Sn-based Pb-free solders with Cu–xZn alloy under bump metallurgies[J]. J. Alloys Compd. 474(1–2), 510–516 (2009)

C.Y. Yu, W.Y. Chen, J.G. Duh, Improving the impact toughness of Sn–Ag–Cu/Cu–Zn Pb-free solder joints under high speed shear testing[J]. J. Alloys Compd. 586, 633–638 (2014)

C. Li, X. Hu, X. Jiang et al., Interfacial reaction and microstructure between the Sn3Ag0. 5Cu solder and Cu–Co dual-phase substrate[J]. Appl. Phys. A 124, 1–13 (2018)

X. Hu, C. Li, Q. Li et al., Insights on interfacial IMCs growth and mechanical strength of asymmetrical Cu/SAC305/Cu–Co system[J]. Vacuum 167, 77–89 (2019)

Q.Q. Lai, L. Zhang, N. Eustathopoulos, Enhanced wetting of dual-phase metallic solids by liquid metals: a new effect of interfacial reaction[J]. Acta Mater. 61(11), 4127–4134 (2013)

H. He, L. Song, H. Gao et al., Microstructure evolution and grain refinement of ultrasonic-assisted soldering joint by using ni foam reinforced Sn composite solder[J]. Ultrason. Sonochem. 92, 106244 (2023)

G.S.B. Lebon, I. Tzanakis, K. Pericleous et al., Ultrasonic liquid metal processing: the essential role of cavitation bubbles in controlling acoustic streaming[J]. Ultrason. Sonochem. 55, 243–255 (2019)

Y. Liu, Y. Bai, J. Chen et al., Control of intermetallic compounds in ultrasonic-assisted sn soldering of Mg/Al alloys[J]. Mater. Design 223, 111235 (2022)

G. Xu, X. Leng, H. Jiang et al., Microstructure and strength of ultrasonic-assisted brazed joints of Si3N4/6061Al composites[J]. J. Manuf. Process. 54, 89–98 (2020)

Y. **ao, Z. Song, S. Li et al., Bonding and strengthening mechanism of ultrasonically soldered 7075 Al joint using Ni-foam/Sn composite solder foil[J]. Mater. Sci. Eng.: A 791, 139691 (2020)

W. Guo, X. Leng, T. Luan et al., Ultrasonic-promoted rapid TLP bonding of fine-grained 7034 high strength aluminum alloys[J]. Ultrason. Sonochem. 36, 354–361 (2017)

X. Hu, H. Xu, W. Chen et al., Effects of ultrasonic treatment on mechanical properties and microstructure evolution of the Cu/SAC305 solder joints[J]. J. Manuf. Process. 64, 648–654 (2021)

Y. Yang, Y. Li, H. Lu et al., Interdiffusion at the interface between Sn-based solders and Cu substrate[J]. Microelectron. Reliab. 53(2), 327–333 (2013)

M.S. Park, R. Arróyave, Computational investigation of intermetallic compounds (Cu6Sn5 and Cu3Sn) growth during solid-state aging process[J]. Comput. Mater. Sci. 50(5), 1692–1700 (2011)

G. Yang, X. Li, E. Ren et al., Morphology evolution and grain orientations of intermetallic compounds during the formation of full Cu3Sn joint[J]. Intermetallics. 145, 107555 (2022)

W. Yang, Y.L. Zhang, W. He et al., Effects of copper content and liquid separation on the microstructure formation of Co–Cu immiscible alloys[J]. Int. J. Mater. Res. 105(9), 861–868 (2014)

W. Yang, S.H. Chen, H. Yu et al., Effects of liquid separation on the microstructure formation and hardness behavior of undercooled Cu–Co alloy[J]. Appl. Phys. A 109, 665–671 (2012)

W. Yang, H. Yu, J.H. Wang et al., Application of dendrite fragmentation to fabricate the homogeneous dispersed structure in undercooled Cu–Co immiscible alloy[J]. J. Alloys Compd. 509(40), 9675–9678 (2011)

C. Wang, C. Kuo, Growth kinetics of the solid-state interfacial reactions in the Sn–Cu/Co and Sn/Co–Cu couples[J]. Mater. Chem. Phys. 130(1–2), 651–656 (2011)

H.J. Dong, Z.L. Li, X.G. Song et al., Grain morphology and mechanical strength of high-melting-temperature intermetallic joints formed in asymmetrical Ni/Sn/Cu system using transient liquid phase soldering process[J]. J. Alloys Compd. 723, 1026–1031 (2017)

Y.S. Goh, Y. Goh, P.Y. Chia et al., Formation and nanomechanical properties of intermetallic compounds in electrodeposited Cu–Sn–Co multilayers[J]. J. Mater. Sci.: Mater. Electron. 32, 9490–9499 (2021)

Y. Qiao, H. Ma, N. Zhao, Diffusion anisotropy induced uneven regional growth of Cu6Sn5 IMC in Cu/SAC305/Cu micro solder joints under temperature gradient[J]. J. Alloys Compd. 886, 161221 (2021)

C. Wang, C. Kuo, S. Huang et al., Temperature effects on liquid-state Sn/Co interfacial reactions[J]. Intermetallics 32, 57–63 (2013)

C. Wang, S. Huang, K. Li, Inhibiting CoSn3 growth at the Sn/Co system by minor Zn addition[J]. Intermetallics. 56, 68–74 (2015)

A.T. Tan, A.W. Tan, F. Yusof, Effect of ultrasonic vibration time on the Cu/Sn–Ag–Cu/Cu joint soldered by low-power-high-frequency ultrasonic-assisted reflow soldering[J]. Ultrason. Sonochem. 34, 616–625 (2017)

B. Wu, X. Leng, Z. **u et al., Microstructural evolution of SiC joints soldered using Zn–Al filler metals with the assistance of ultrasound[J]. Ultrason. Sonochem. 44, 280–287 (2018)

H. Wang, X. Hu, X. Jiang et al., Interfacial reaction and shear strength of ultrasonically-assisted Sn–Ag–Cu solder joint using composite flux[J]. J. Manuf. Process 62, 291–301 (2021)

X. Yi, R. Zhang, X. Hu, Study on the microstructure and mechanical property of Cu-foam modified Sn3.0Ag0.5Cu solder joints by ultrasonic-assisted soldering[J]. J. Manuf. Process. 64, 508–517 (2021)

Acknowledgements

This work was supported by the National Natural Science Foundation of China (No. 52165047).

Funding

This study was funded by National Natural Science Foundation of China, Grant Number 52165047, **aowu Hu.

Author information

Authors and Affiliations

Contributions

JW: Conceptualization, Methodology, Sample Preparation, Formal analysis, Investigation, Data curation, Writing—original draft, Visualization. WC: Investigation, Data curation, Visualization. DL: Conceptualization, Methodology, Formal analysis, Investigation, Data curation, Visualization. CL: Methodology, Sample Preparation, Formal analysis, Investigation, Data curation. JZ: Methodology, Supervision, Resources, Writing—review & editing. ZZ: Sample Preparation, Formal analysis, Data curation. BC: Writing—original draft, Supervision. XJ: Investigation, Formal analysis. XH: Conceptualization, Methodology, Formal analysis, Investigation, Writing—original draft, Visualization.

Corresponding authors

Ethics declarations

Competing interests

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Wang, J., Chen, W., Liu, D. et al. Effect of the ultrasonic-assisted soldering on the interfacial reaction and IMC growth behavior of SAC305 solder with Cu alloy substrates. J Mater Sci: Mater Electron 34, 1517 (2023). https://doi.org/10.1007/s10854-023-10959-w

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s10854-023-10959-w