Abstract

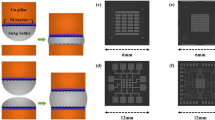

Hourglass-shaped microbump joints are expected to be used in three-dimensional (3D) chip stacking interconnect technology due to their strong resistance to electromigration and great underfill compatibility. However, the development of hourglass-shaped joints was challenged by their mechanical strength concerns. In this study, hourglass-shaped microbump joints were formed by stretching the microbump joints during the thermocompression bonding (TCB) process. Meanwhile, a high temperature gradient was introduced into the microbump joints to enable rapid diffusion growth of intermetallic compound (IMC) in Sn-3.5Ag solder, which greatly improved the strength of the microbump joints. The full-IMC microbump joint (108.1 MPa) is twice as strong as the non-full-IMC microbump joint (54.6 MPa), and the 40-µm joints showed even higher strength than that of conventional non-full-IMC microbump joints of 100 μm. The shear test revealed that the hourglass-shaped microbump joint fracture location appeared at the waist rather than near the IMC layer. The fracture mode changed from mixed ductile-brittle fracture to brittle fracture after the transition to full-IMC microbump joints.

Similar content being viewed by others

Data availability

Data will be made available on reasonable request.

References

X.W. Zhang, Jk. Lin, S. Wickramanayaka, S.B. Zhang, R. Weerasekera, R. Dutta, K.F. Chang, K.J. Chui, H.Y. Li, D.S.W. Ho, L. Ding, G. Katti, S. Bhattacharya, D.L. Kwong, Heterogeneous 2.5D integration on through silicon interposer. Appl. Phys. Rev. 2(2), 021308 (2015)

M.M. Waldrop, The semiconductor industry will soon abandon its, pursuit of moore’s law, now things could get a lot more interesting. Nature 530, 144–147 (2016)

T. Huang, S.Y. Liu, H.Q. Ling, M. Li, A.M. Hu, L.M. Gao, T. Hang, Growth behavior and morphology of sidewall intermetallic compounds in Cu/Ni/sn-Ag microbumps during multiple reflows. Mater. Lett. 326, 132877 (2022)

C. Tang, Z. Chen, M.A. Fang, X.Y. **ao, G. Chen, W.H. Zhu, Size effects on IMC growth of Cu/Ni/Sn-3.5Ag microbump joints during isothermal aging and prediction of shear strength using ANN. J. Mater. Res. Technol. 18, 1865–1885 (2022)

C.Y. Khor, M.Z. Abdullah, F.C. Ani, Underfill process for two parallel plates and flip chip packaging. Int. Commun. Heat Mass Transfer. 39, 1205–1212 (2012)

Y.H. Hsiao, K.L. Lin, The formation and conversion of intermetallic compounds in the Cu pillar Sn-Ag micro-bump with ENEPIG Cu substrate under current stressing. J. Mater. Sci.-Mater. Electron. 27, 2201–2205 (2016)

F.C. Ng, A. Abas, M.Z. Abdullah, Effect of solder bump shapes on underfill flow in flip-chip encapsulation using analytical, numerical and PIV experimental approaches. Microelectron. Reliab. 81, 41–63 (2018)

P. Chen, X.C. Zhao, Y. Wang, Y. Liu, H. Li, Y. Gu, Enhancement of mean-time-to-failure of Sn3.0Ag0.5Cu solder bump joint under current stressing via controlling bump shape. J. Mater. Sci.-Mater. Electron. 26, 1940–1949 (2015)

P. Chen, X.C. Zhao, Y. Liu, H. Li, Y. Wang, Aging resistance and mechanical properties of Sn3.0Ag0.5Cu solder bump joints with different bump shapes. Rare Met. 40, 225–230 (2021)

M.S. Kim, M.S. Kang, J.H. Bang, C.W. Lee, M.S. Kim, S. Yoo, Interfacial reactions of fine-pitch Cu/Sn-3.5Ag pillar joints on Cu/Zn and Cu/Ni under bump metallurgies. J. Alloys Compd. 616, 394–400 (2014)

C. Tang, W.H. Zhu, Z. Chen, L.C. Wang, Thermomechanical reliability of a Cu/Sn-3.5Ag solder joint with a ni insertion layer in flip chip bonding for 3D interconnection. J. Mater. Sci.-Mater. Electron. 32, 11893–11909 (2021)

P. Yao, X.Y. Li, X. Han, L.F. Xu, Shear strength and fracture mechanism for full Cu-Sn IMCs solder joints with different Cu3Sn proportion and joints with conventional interfacial structure in electronic packaging. Solder. Surf. Mount. Technology. 31, 6–19 (2019)

G.L. Yang, X.Y. Li, E.H. Ren, S.S. Li, Morphology evolution and grain orientations of intermetallic compounds during the formation of full Cu3Sn joint. Intermetallics 145, 107555 (2022)

T.L. Yang, T. Aoki, K. Matsumoto, K. Toriyama, A. Horibe, H. Mori, Y. Orii, J.Y. Wu, C.R. Kao, Full intermetallic joints for chip stacking by using thermal gradient bonding. Acta Mater. 113, 90–97 (2016)

Y.Q. Lai, N. Zhao, Study on the evolution of interfacial (Cu,Ni)(6)Sn-5 and shear property of (111)Cu/Sn/Ni micro joints under isothermal and TG-bonding. Intermetallics 147, 107614 (2022)

J.Y. Feng, C.J. Hang, Y.H. Tian, C.X. Wang, B.L. Liu, Effect of electric current on grain orientation and mechanical properties of Cu-Sn intermetallic compounds joints. J. Alloys Compd. 753, 203–211 (2018)

H. Cao, Y. Zhang, Y. Zhang, J. Han, D. Su, Z. Zhang, Effect of the anisotropic characteristics of β-Sn on current-induced solder evolution. Mater. Design 224, 111339 (2022)

H.Y. Zhao, J.H. Liu, Z.L. Li, X.G. Song, Y.X. Zhao, H.W. Niu, H. Tian, H.J. Dong, J.C. Feng, A comparative study on the microstructure and Mechanical Properties of Cu6Sn5 and Cu3Sn joints formed by TLP soldering With/Without the assistance of Ultrasonic waves. Metall. Mater. Trans. a-Phys. Metall. Mater. Sci. 49A, 2739–2749 (2018)

X. Han, X.Y. Li, P. Yao, D.L. Chen, Influence of ultrasounds on interfacial microstructures of Cu-Sn solder joints. Solder. Surf. Mount. Technol. 33, 206–214 (2021)

F.Y. Ouyang, W.C. Jhu, T.C. Chang, Thermal-gradient induced abnormal Ni3Sn4 interfacial growth at cold side in Sn2.5Ag alloys for three-dimensional integrated circuits. J. Alloys Compd. 580, 114–119 (2013)

S. Baek, G.W. Jeong, J.H. Son, M.S. Kim, H.B.R. Lee, J. Kim, Y.H. Ko, Interfacial reactions and mechanical properties of transient liquid-phase bonding joints in Cu/Sn/Ni(P) and Ni/Sn/(OSP)Cu structures for power modules. J. Mater. Sci.-Mater. Electron. 32, 3324–3333 (2021)

M.G. Fang, C. Tang, Y.M. Chen, J.H. Li, Z. Chen, F.L. Wang, W.H. Zhu, Thermo-compression bonding process characteristics and shape control of Cu-pillar microbump joints by optimizing of solder melting. J. Mater. Sci.-Mater. Electron. 33, 10471–10485 (2022)

H.T. Lee, M.H. Chen, H.M. Jao, T.L. Liao, Influence of interfacial intermetallic compound on fracture behavior of solder joints. Mater. Sci. Eng. a-Struct. Mater. Prop. Microstruct. Process 358, 134–141 (2003)

H.Y. Chen, C. Chen, Thermomigration of Cu-Sn and Ni-Sn intermetallic compounds during electromigration in Pb-free SnAg solder joints. J. Mater. Res. 26, 983–991 (2011)

A. Kunwar, H.R. Ma, H.T. Ma, J.H. Sun, N. Zhao, M.L. Huang, On the increase of intermetallic compound’s thickness at the cold side in liquid sn and SnAg solders under thermal gradient. Mater. Lett. 172, 211–215 (2016)

H.T. Ma, A. Kunwar, J.H. Sun, B.F. Guo, Ma. In situ study on the increase of intermetallic compound thickness at anode of molten tin due to electromigration of copper. Scripta Mater. 107, 88–91 (2015)

Y.S. Yang, C.J. Yang, F.Y. Ouyang, Interfacial reaction of Ni3Sn4 intermetallic compound in Ni/SnAg solder/Ni system under thermomigration. J. Alloys Compd. 674, 331–340 (2016)

D.G. Kim, J.W. Kim, J.G. Lee, H. Mori, D.J. Quesnel, S.B. Jung, Solid state interfacial reaction and joint strength of Sn-37Pb solder with Ni-P under bump metallization in flip chip application. J. Alloys Compd. 395, 80–87 (2005)

T.T. Dele-Afolabi, M.A.A. Hanim, M. Norkhairunnisa, H.M. Yusoff, M.T. Suraya, Investigating the effect of isothermal aging on the morphology and shear strength of Sn-5Sb solder reinforced with carbon nanotubes. J. Alloys Compd. 649, 368–374 (2015)

X.W. Hu, T. Xu, L.M. Keer, Y.L. Li, X.X. Jiang, Microstructure evolution and shear fracture behavior of aged Sn3Ag0. 5Cu/Cu solder joints. Mater. Sci. Eng. a-Struct. Mater. Prop. Microstruct. Process 673, 167–177 (2016)

G.Y. Jang, J.W. Lee, J.G. Duh, The nanoindentation characteristics of Cu6Sn5, Cu3Sn, and Ni3Sn4 intermetallic compounds in the solder bump. J. Electron. Mater. 33, 1103–1110 (2004)

R.R. Chromik, R.P. Vinci, S.L. Allen, M.R. Notis, Nanoindentation measurements on Cu-Sn and Ag-Sn intermetallics formed in Pb-free solder joints. J. Mater. Res. 18, 2251–2261 (2003)

M. Abtew, G. Selvaduray, Lead-free solders in microelectronics. Mater. Sci. Eng. R-Rep. 27, 95–141 (2000)

Qk. Zhang, J. Tan, Z.F. Zhang, Fracture behaviors and strength of Cu6Sn5 intermetallic compounds by indentation testing. J. Appl. Phys. 110(1), 014502 (2011)

H.C. Cheng, C.F. Yu, W.H. Chen, Strain- and strain-rate-dependent mechanical properties and behaviors of Cu3Sn compound using molecular dynamics simulation. J. Mater. Sci. 47, 3103–3114 (2012)

X.S. Liu, G.Q. Lu, Effects of solder joint shape and height on thermal fatigue lifetime. IEEE Trans. Compon. Packag. Technol. 26, 455–465 (2003)

Acknowledgements

This work is supported by National Natural Science Foundation of China (Grant No. U20A6004), Key Project of Science and Technology of Changsha (kq2102005), Natural Science Foundation of Hunan Province (Grant No. 2021JJ40734).

Author information

Authors and Affiliations

Contributions

CT: data curation, writing - original draft. ZC: methodology, writing-review and editing, supervision. WZ: conceptualization, methodology.

Corresponding authors

Ethics declarations

Conflict of interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Tang, C., Chen, Z. & Zhu, W. Effect of introducing high temperature gradients on IMC growth and shear properties in hourglass-shaped microbump joints during thermocompression bonding. J Mater Sci: Mater Electron 34, 702 (2023). https://doi.org/10.1007/s10854-023-10124-3

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s10854-023-10124-3