Abstract

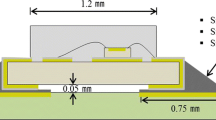

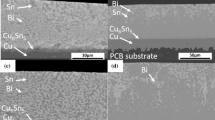

Solder joints of Au-20wt%Sn (Au-20Sn) between real light-emitting diode Si chips and AlN substrates were fabricated using thermo-compression (TC) bonding. We investigated the microstructure of TC-bonded solder joints using scanning electron microscopy, transmission electron microscopy (TEM), and scanning transmission electron microscopy (STEM) and its effect on shear strength. The metallization system for the Au-20Sn solder consisted of Pt/Ti thin films on Si chips and an electroless Ni/Pd/Au layer on AlN substrates. The TC bonding was carried out at 280, 290, 300, and 310 °C for 0.2, 0.6, and 1.2 s. Samples were aged at 200 °C for up to 1000 h in a conventional oven. The performance of the solder joints was sensitive to joining temperature. When the solder joint was formed at a relatively low temperature, shear strength was low due to the unbonded regions in the solder joints. The shear strength increased with joining temperature and time. When the solder joints were formed at a relatively high temperature, shear strength was high. The solder joints were composed of δ-phase at both interfaces and ζ’-phase at the center. After aging at 200 °C for up to 1000 h, shear strength slightly decreased. The main fracture modes before and after aging were Si cohesive fracture and interfacial fracture between Si and Ti, respectively. TEM and STEM clearly indicated that the Pt layer remained at the solder interface after aging. The high shear strength was attributed to the strong interface between Pt and the Au-20Sn solder.

Similar content being viewed by others

Data Availability

All data generated or analyzed during this study are included in this published article and its supplementary information files.

References

H.H. Kim, S.H. Choi, S.H. Shin, Y.K. Lee, S.M. Choi, S. Yi, Microelectron. Reliab. 48, 445 (2008)

K. Chu, C. Lee, S.H. Park, Y. Sohn, J. Mater. Sci. Mater. Electron. 28, 5174 (2017)

J.W. Yoon, H.S. Chun, S.B. Jung, Mater. Sci. Eng. A 473, 119 (2008)

V. Grolier, R. Schmid-Fetzer, J. Electron. Mater. 37, 815 (2008)

J.W. Yoon, H.S. Chun, S.B. Jung, J. Alloys Compd. 469, 108 (2009)

R.W. Chuang, D. Kim, J. Park, C.C. Lee, IEEE Trans. Components Packag Technol. 27, 177 (2004)

J.C. McNulty, Proc. – 2008 Int. Symp. Microelectron. IMAPS 2008 909 (2008)

S. Anhock, H. Oppermann, C. Kallmayer, R. Aschenbrenner, L. Thomas, H. Reichl, Proc. IEEE/CPMT Int. Electron. Manuf. Technol. Symp. 156 (1998)

O. Wada, T. Kumai, Appl. Phys. Lett. 58, 908 (1991)

S.C. Yang, W.C. Chang, Y.W. Wang, C.R. Kao, J. Electron. Mater. 38, 25 (2009)

J.H. Park, J.H. Lee, Y.H. Lee, Y.S. Kim, J. Electron. Mater. 31, 1175 (2002)

H. Dong, V. Vuorinen, M. Broas, M. Paulasto-Kröckel, J. Alloys Compd. 688, 388 (2016)

S.S. Kim, J.H. Kim, S.W. Booh, T.G. Kim, H.M. Lee, Mater. Trans. 46, 2400 (2005)

J.Y. Tsai, C.W. Chang, C.E. Ho, Y.L. Lin, C.R. Kao, J. Electron. Mater. 35, 65 (2006)

H.Q. Dong, V. Vuorinen, X.W. Liu, T. Laurila, J. Li, M. Paulasto-Kröckel, J. Electron. Mater. 45, 566 (2016)

H.G. Song, J.P. Ahn, J.W. Morris, J. Electron. Mater. 30, 1083 (2001)

H.Q. Dong, V. Vuorinen, T. Laurila, M. Paulasto-Kröckel, Calphad Comput. Coupling Phase Diagrams Thermochem 43, 61 (2013)

J. Peng, R.C. Wang, H.S. Liu, J.Y. Li, J. Mater. Sci. Mater. Electron. 29, 313 (2018)

P. Lin, W. Liu, Y. Ma, Y. Huang, S. Tang, J. Mater. Sci. Mater. Electron. 31, 19013 (2020)

J.-M. Han, I.-J. Seo, Y. Ahn, Y.-S. Ko, T.-H. Kim, J. Korean Soc. Manuf. Technol. Eng. 23, 355 (2014)

T. Tak-seng, D. Sun, H. Koay, M. Sabudin, J. Thompson, P. Martin, P. Rajkomar, S. Haque, EMAP2005. 118 (2005)

H.P. Park, G. Seo, S. Kim, K. one Ahn, Y.H. Kim (2019) J. Mater. Sci. Mater. Electron. 30, 1055

H. Ru, V. Wei, T. Jiang, M. Chiu, Proc. Int. Microsystems, Packag. Assem. Circuits Technol. Conf. IMPACT 311 (2011)

J.W. Ronnie Teo, F.L. Ng, L.S. Kip Goi, Y.F. Sun, Z.F. Wang, X.Q. Shi, J. Wei, G.Y. Li, Microelectron. Eng. 85, 512 (2008)

L.L. Liao, K.N. Chiang, J. Mech. 35, 81 (2019)

S.W. Yoon, W.K. Choi, H.M. Lee, Acta Metall. 40, 297 (1999)

A. Rautiainen, V. Vuorinen, H. Heikkinen, M. Paulasto-Krockel, IEEE Trans. Components Packag Manuf. Technol. 8, 169 (2018)

I. Corporation, https://www.indium.com/technical-documents/product-data-sheets/download/3714(2017)

Acknowledgements

This research was supported by an LED business team collaborative project between Hanyang University and Samsung Electronics Co. Ltd.

Author information

Authors and Affiliations

Contributions

DL, JJ, and YK wrote the paper.

Corresponding author

Ethics declarations

Conflict of interest

The authors declare no conflict of interest.

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Lee, Dh., Jang, Ji. & Kim, YH. Microstructure and shear strength of Au-20wt%Sn solder joints fabricated by thermo-compression bonding for LED packages. J Mater Sci: Mater Electron 33, 11002–11016 (2022). https://doi.org/10.1007/s10854-022-08079-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10854-022-08079-y