Abstract

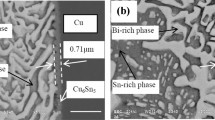

The effect of nickel metallization thickness on microstructure evolution and mechanical properties in Sn3.0Ag0.5Cu/Au/Ni/Cu solder joints was investigated here. First, a single-layer Cu–Ni–Au–Ag–Sn IMC formed at the interface after reflow and then differentiated into double layers during solid-state aging in both 3-μm nickel metallization (S1) and 6-μm nickel metallization (S2) samples. The interfacial IMC which closes to solder was recorded as (Cu, Au, Ni)6Sn5 and the other which closes to Ni metallization was recorded as (Cu, Ni, Au)6Sn5. The (Cu, Au, Ni)6Sn5 IMC kept growing in S1 during solid-state aging, whereas it experienced a negative growth among 500 h to 1000 h in S2. The growth trend of (Cu, Ni, Au)6Sn5 is contrary to (Cu, Au, Ni)6Sn5 and it decreased firstly then increased in both S1 and S2. Second, S1 exhibits higher shear force and lower frequency of interface fracture than S2, due to a thinner (Cu, Ni, Au)6Sn5 layer in S1. (Cu, Ni, Au)6Sn5 is more critical than (Cu, Au, Ni)6Sn5 on the failure process of solder joint. The negative growth of (Cu, Ni, Au)6Sn5 corresponds to the rising of shear forces and the interface of (Cu, Ni, Au)6Sn5/Ni is the weakest position in solder joints. Finally, the fracture behavior of AuSn4 was investigated in detail. AuSn4 with lamellar shaped dispersed in solder joint after reflow. It connected with the interfacial IMC and this structure can transfer fracture from inside of the solder ball to the interface. It resulted in decreasing of shear force and interfacial fracture. After 250 h of solid-state aging, AuSn4 became crumb shaped dispersing in solder joint and did not transfer fracture.

Similar content being viewed by others

References

M. Sona, K.N. Prabhu, J. Mater. Sci. Mater. Electron. 24, 3149 (2013)

C.C. Chi, L.C. Tsao, C.W. Tsao, T.H. Chuang, J. Mater. Eng. Perform. 17, 134 (2008)

J. Chen, J. Shen, W.D. **e, H. Liu, J. Mater. Sci. Mater. Electron. 22, 1703 (2011)

J.M. Kim, M.H. Jeong, S. Yoo, Y.B. Park, J. Electron. Mater. 41, 791 (2012)

M.Y. **ong, L. Zhang, J. Mater. Sci. 54, 1741 (2019)

K. Zeng, K.N. Tu, Mater. Sci. Eng. R-Rep. 38, 55 (2002)

X.J. Huang, S.W. RickyLee, M. Li, W.T. Chen, IEEE Trans. Electron. Packag. Manuf. 31, 185 (2008)

M.O. Alam, B.Y. Wu, Y.C. Chan, L. Rufer, IEEE Trans. Device Mater. Reliab. 6, 421 (2006)

C.E. Ho, W.T. Chen, C.R. Kao, J. Electron. Mater. 30, 379 (2001)

C.E. Ho, L.C. Shiau, C.R. Kao, J. Electron. Mater. 31, 1264 (2002)

Y.L. Lin, W.C. Luo, Y.H. Lin, C.E. Ho, C.R. Kao, J. Electron. Mater. 33, 1092 (2004)

A.M. Minor, J.W. Morris, J. Electron. Mater. 29, 1170 (2000)

C.E. Ho, W.H. Wu, C.C. Wang, Y.C. Lin, J. Electron. Mater. 41, 3266 (2012)

M.E. Ferguson, C.D. Fieselman, M.A. Elkins, IEEE Trans. Compnd. Pack. Manuf. Technol. 20, 188 (1997)

W.L. Shin, T.L. Yang, H.Y. Chuang, M.S. Kuo, C.R. Kao, J. Electron. Mater. 43, 4262 (2014)

N. Duan, J. Scheer, J. Bielen, M.V. Kleef, Microelectron. Reliab. 43, 1317 (2003)

D.T. Rooney, L. Gullo, D.J. **e, N.T. Castello, D.K. Shangguan, Microelectron. Reliab. 47, 2152 (2007)

K. Pun, P.L. Eu, M.N. Islam, C.Q.Cui, Effect of Ni layer Thickness on intermetallic formation and mechanical strength of Sn–Ag–Cu solder joint. 10th Electronics Packing Technology Conference, 09–12 Dec 2008 (pp. 487). IEEE

C.E. Ho, M.K. Lu, P.T. Lee, Y.H. Huang, W.L. Chou, Mater. Sci. Eng. A 706, 269 (2017)

R.Y. Tian, C.J. Hang, Y.H. Tian, J.Y. Feng, J. Alloy. Compd. 777, 463 (2019)

C.L. Liang, K.L. Lin, P.J. Cheng, J. Mater. Sci. Mater. Electron. 29, 15233 (2018)

C.E. Ho, S.C. Yang, C.R. Kao, J. Mater. Sci. Mater. Electron. 18, 155 (2007)

S.W. Fu, C.Y. Yu, T.K. Lee, K.C. Liu, J.G. Duh, Mater. Lett. 80, 103 (2012)

I.T. Wang, J.G. Duh, C.Y. Cheng, J. Wang, Mater. Sci. Eng. B 177, 278 (2012)

F. Gao, T. Takemoto, H. Nishikawa, Mater. Sci. Eng. A 420, 39 (2006)

J.Q. Huang, M.B. Zhou, S.B. Liang, X.P. Zhang, J. Mater. Sci. Mater. Electron. 29, 7651 (2018)

C.L. Liang, K.L. Lin, P.J. Cheng, J. Mater. Sci. 52, 11659 (2017)

K.N. Tu, K. Zeng, Mater. Sci. Eng. R-Rep. 34, 1 (2001)

J.W. Yoon, S.W. Kim, S.B. Jung, J. Alloy. Compd. 391, 82 (2005)

L.C. Shiau, C.E. Ho, C.R. Kao, Solder. Surf. Mt. Technol. 14, 25 (2002)

A.M. Minor, J.W. Morris, Metall. Mater. Trans. A 31, 798 (2000)

Acknowledgements

The authors are grateful for financial support from the National Natural Science Foundation of China (No. U1637203).

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Lin, Y., Li, H. & Chen, G. Effect of nickel metallization thickness on microstructure evolution and mechanical properties in Sn3.0Ag0.5Cu/Au/Ni/Cu solder joints. J Mater Sci: Mater Electron 31, 11569–11580 (2020). https://doi.org/10.1007/s10854-020-03705-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10854-020-03705-z