Abstract

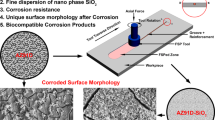

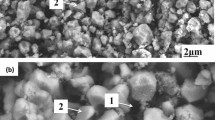

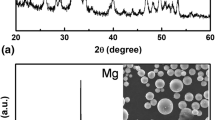

Magnesium (Mg) alloys are gaining more attention in recent times as biodegradable materials. However, two major problems with Mg alloy implants are bacterial infections and poor corrosion resistance. In this context, a composite surface (Mg–Zn–Dy–Al2O3/HA) is developed using surface modification techniques. First, Al2O3 + HA composite powder is coated on Mg–Zn–Dy alloy to attain coated surface (C-AHa). Next, the C-AHa surface is subjected to friction stir processing to develop composite surface (F-AHa). Microstructural characterization reveals that, the Al2O3 + HA particles were distributed evenly into the Mg–Zn–Dy substrate. Antimicrobial activities against Escherichia coli and Staphylococcus aureus reveal low adhesion of bacteria on the F-AHa sample surface due to low surface energy (37.83 ± 0.22 mN/m) and low surface roughness (0.36 ± 0.1 µm). Further, the cytotoxicity tests confirm that the F-AHa sample shows significant improvement in cell viability (98%) after 7 days and non-toxic against the mouse osteoblast cells. In Vitro corrosion study observations demonstrate that the corrosion rate for the F-AHa sample is decreased by 72% compared to the C-AHa sample. Thus, the results of this study for the fabricated composites are promising for antimicrobial, biocompatible and bioabsorbable temporary implants.

Similar content being viewed by others

Data availability

Data available on request.

References

Li H, Zheng Y, Qin L (2014) Progress of biodegradable metals. Prog Nat Sci Mater Int 24:414–422. https://doi.org/10.1016/j.pnsc.2014.08.014

Narayan RJ (2010) The next generation of biomaterial development. Philos Trans R Soc A Math Phys Eng Sci 368:1831–1837. https://doi.org/10.1098/rsta.2010.0001

Hermawan H (2012) Biodegradable metals: state of the art, pp 13–22. https://doi.org/10.1007/978-3-642-31170-3_2

Ezechieli M, Ettinger M, König C, Weizbauer A, Helmecke P, Schavan R et al (2016) Biomechanical characteristics of bioabsorbable magnesium-based (MgYREZr-alloy) interference screws with different threads. Knee Surg Sport Traumatol Arthrosc 24:3976–3981. https://doi.org/10.1007/s00167-014-3325-6

Johnston S, Lau C, Dargusch MS, Atrens A (2019) Absorbable Mg surgical tack: proof of concept and in situ fixation strength. J Mech Behavior of Biomed Mater 97:321–329. https://doi.org/10.1016/j.jmbbm.2019.05.035

Li M, Jiang M, Gao Y, Zheng Y, Liu Z, Zhou C et al (2022) Current status and outlook of biodegradable metals in neuroscience and their potential applications as cerebral vascular stent materials. Bioact Mater 11:140–153. https://doi.org/10.1016/j.bioactmat.2021.09.025

Witte F (2015) Reprint of: the history of biodegradable magnesium implants: a review. Acta Biomater 23:S28-40. https://doi.org/10.1016/j.actbio.2015.07.017

Song J, Chen J, **ong X, Peng X, Chen D, Pan F (2022) Research advances of magnesium and magnesium alloys worldwide in 2021. J Magnes Alloy 10:863–898. https://doi.org/10.1016/j.jma.2022.04.001

Zheng YF, Gu XN, Witte F (2014) Biodegradable metals. Mater Sci Eng A 77:1–34

Atrens BA, Song G, Liu M, Shi Z, Cao F, Dargusch MS (2015) Review of recent developments in the field of magnesium corrosion. Adv Eng Mater 17:1–54. https://doi.org/10.1002/adem.201400434

Song BG, Atrens A (2003) Understanding magnesium corrosion a framework for improved alloy performance. Adv Eng Mater 5:837–58. https://doi.org/10.1002/adem.200310405

Song G, Atrens A (2007) Recent insights into the mechanism of magnesium corrosion and research suggestions. Adv Eng Mater 9:177–183. https://doi.org/10.1002/adem.200600221

Manne B, Thiruvayapati H, Bontha S (2018) Surface and coatings technology surface design of Mg–Zn alloy temporary orthopaedic implants : tailoring wettability and biodegradability using laser surface melting. Surf Coat Technol 347:337–349. https://doi.org/10.1016/j.surfcoat.2018.05.017

Kottuparambil RR, Bontha S, Rangarasaiah RM, Arya SB, Jana A, Das M et al (2018) Effect of zinc and rare-earth element addition on mechanical, corrosion, and biological properties of magnesium. J Mater Res 33:3466–3478. https://doi.org/10.1557/jmr.2018.311

Cai S, Lei T, Li N, Feng F (2012) Effects of Zn on microstructure, mechanical properties and corrosion behavior of Mg–Zn alloys. Mater Sci Eng C 32:2570–2577. https://doi.org/10.1016/j.msec.2012.07.042

Brar HS, Wong J, Manuel MV (2012) Investigation of the mechanical and degradation properties of Mg–Sr and Mg–Zn–Sr alloys for use as potential biodegradable implant materials. J Mech Behav Biomed Mater 7:87–95. https://doi.org/10.1016/j.jmbbm.2011.07.018

Sudha P, Tun KS, Gupta M, Kumar G, Vincent S (2022) Biocorrosion studies of a novel Mg70Al18Zn6Ca4Y2 low entropy multicomponent alloy in different simulated body fluids. J Appl Electrochem 52:1109–1120. https://doi.org/10.1007/s10800-022-01685-y

Praveen TR, Shivananda Nayaka H, Swaroop S, Gopi KR (2020) Strength enhancement of magnesium alloy through equal channel angular pressing and laser shock peening. Appl Surf Sci 512:145755. https://doi.org/10.1016/j.apsusc.2020.145755

Ali M, Elsherif M, Salih AE, Ul-hamid A, Hussein MA, Park S et al (2020) Surface modification and cytotoxicity of Mg–based bio-alloys: an overview of recent advances. J Alloys Compd 825:154140. https://doi.org/10.1016/j.jallcom.2020.154140

Wu G, Ibrahim JM, Chu PK (2013) Surface and coatings technology surface design of biodegradable magnesium alloys—a review. Surf Coat Technol 233:2–12. https://doi.org/10.1016/j.surfcoat.2012.10.009

Huynh V, Ngo NK, Golden TD (2019) Surface activation and pretreatments for biocompatible metals and alloys used in biomedical applications. Int J Biomater 2019:1–21. https://doi.org/10.1155/2019/3806504

Jana A, Das M, Krishna V (2020) Effect of heat treatment on microstructure mechanical corrosion and biocompatibility of Mg–Zn–Zr–Gd–Nd alloy. J Alloys Compd 821:153462. https://doi.org/10.1016/j.jallcom.2019.153462

Zhang J, **n C, Nie K, Cheng W, Wang H, Xu C (2014) Microstructure and mechanical properties of Mg–Zn–Dy–Zr alloy with long-period stacking ordered phases by heat treatments and ECAP process. Mater Sci Eng A 611:108–113. https://doi.org/10.1016/j.msea.2014.05.067

Liu SJ, Yang GY, Luo SF, Jie WQ (2015) Microstructure and mechanical properties of sand mold cast Mg-4.58Zn-2.6Gd-0.18Zr magnesium alloy after different heat treatments. J Alloys Compd 644:846–853. https://doi.org/10.1016/j.jallcom.2015.05.062

Li J, Jiang Q, Sun H, Li Y (2016) Effect of heat treatment on corrosion behavior of AZ63 magnesium alloy in 3.5 wt% sodium chloride solution. Corros Sci 111:288–301. https://doi.org/10.1016/j.corsci.2016.05.019

Mukhametkaliyev TM, Surmeneva MA, Vladescu A, Cotrut CM, Braic M, Dinu M et al (2017) A biodegradable AZ91 magnesium alloy coated with a thin nanostructured hydroxyapatite for improving the corrosion resistance. Mater Sci Eng C 75:95–103. https://doi.org/10.1016/j.msec.2017.02.033

Lin X, Wang X, Tan L, Wan P, Yu X, Li Q et al (2014) Effect of preparation parameters on the properties of hydroxyapatite containing micro-arc oxidation coating on biodegradable ZK60 magnesium alloy. Ceram Int 40:10043–51. https://doi.org/10.1016/j.ceramint.2014.02.104

Rojaee R, Fathi M, Raeissi K, Taherian M (2014) Electrophoretic deposition of bioactive glass nanopowders on magnesium based alloy for biomedical applications. Ceram Int 40:7879–7888. https://doi.org/10.1016/j.ceramint.2013.12.135

Mardali M, Salimijazi H, Karimzadeh F (2018) Fabrication and characterization of nanostructured hydroxyapatite coating on Mg-based alloy by high-velocity oxygen fuel spraying. Ceram Int 44:14667–14676. https://doi.org/10.1016/j.ceramint.2018.05.093

Singh N, Batra U, Kumar K, Ahuja N, Mahapatro A (2023) Progress in bioactive surface coatings on biodegradable Mg alloys: a critical review towards clinical translation. Bioact Mater 19:717–757. https://doi.org/10.1016/j.bioactmat.2022.05.009

Zhao MC, Zhao YC, Yin DF, Wang S, Shangguan YM, Liu C et al (2019) Biodegradation behavior of coated as-extruded Mg–Sr alloy in simulated body fluid. Acta Metall Sin (English Lett) 32:1195–206. https://doi.org/10.1007/s40195-019-00892-5

Rakesh KR, Bontha S, Mitun RMR, Vamsi D, Balla K (2020) Degradation wettability and surface characteristics of laser surface modified Mg–Zn–Gd–Nd alloy. J Mater Sci Mater Med 31(5):1–15. https://doi.org/10.1007/s10856-020-06383-9

Kasemo B (2002) Biological surface science. Surf Sci 500:656–677. https://doi.org/10.1016/S0039-6028(01)01809-X

Olivier V, Faucheux N, Hardouin P (2004) Biomaterial challenges and approaches to stem cell use in bone reconstructive surgery. Drug Discov Today 9:803–811. https://doi.org/10.1016/S1359-6446(04)03222-2

Mishra RS (2005) Friction stir welding and processing. Mater Sci Eng R 50:1–78. https://doi.org/10.1016/j.mser.2005.07.001

Patel V, Li W, Andersson J, Li N (2022) Enhancing grain refinement and corrosion behavior in AZ31B magnesium alloy via stationary shoulder friction stir processing. J Mater Res Technol 17:3150–3156. https://doi.org/10.1016/j.jmrt.2022.02.059

Khan F, Karthik GM, Panigrahi SK, Ram GDJ (2019) Materials characterization friction stir processing of QE22 magnesium alloy to achieve ultra fi ne-grained microstructure with enhanced room temperature ductility and texture weakening. Mater Charact 147:365–378. https://doi.org/10.1016/j.matchar.2018.11.020

Sharma GK, Kumar K, Grewal NS (2024) Microstructure refinement and augmenting mechanical properties of Mg alloy using friction stir processing. J Mater Eng Perform. https://doi.org/10.1007/s11665-024-09311-y

Mohankumar A, Duraisamy T, Chidambaramseshadri R, Pattabi T, Ranganathan S, Kaliyamoorthy M et al (2022) Enhancing the corrosion resistance of low pressure cold sprayed metal matrix composite coatings on AZ31B Mg alloy through friction stir processing. Coatings 12:4–7. https://doi.org/10.3390/coatings12020135

Manroo SA, Khan NZ, Ahmad B (2022) Development of nano-composites on rare-earth Mg-ZE41 alloy via friction stir processing (FSP): microstructure, mechanical, and tribological properties. Jom 74:2047–2062. https://doi.org/10.1007/s11837-022-05211-5

Khan MA, Butola R, Gupta N (2022) A review of nanoparticle reinforced surface composites processed by friction stir processing. J Adhes Sci Technol 0:1–37. https://doi.org/10.1080/01694243.2022.2037054

Singla S, Sagar P, Handa A (2023) Recent advances in magnesium-based metal matrix surface composites developed via friction stir processing route—an overview. Metallogr Microstruct Anal 12:385–400. https://doi.org/10.1007/s13632-023-00969-9

Mehdizade M, Eivani AR, Tabatabaei F, Jafarian HR, Zhou J (2022) Microstructural basis for improved corrosion resistance and mechanical properties of fabricated ultra-fine grained Mg-Akermanite composites. Mater Chem Phys 292:126765. https://doi.org/10.1016/j.matchemphys.2022.126765

Perumal G, Chakrabarti A, Grewal HS, Pati S, Singh S, Arora HS (2019) Enhanced antibacterial properties and the cellular response of stainless steel through friction stir processing. Biofouling 35:187–203. https://doi.org/10.1080/08927014.2019.1584794

Hanas T, Sampath Kumar TS, Perumal G, Doble M, Ramakrishna S (2018) Electrospun PCL/HA coated friction stir processed AZ31/HA composites for degradable implant applications. J Mater Process Technol 252:398–406. https://doi.org/10.1016/j.jmatprotec.2017.10.009

Mehdizade M, Eivani AR, Esmaielzadeh O, Tabatabaei F (2023) Fabrication of osteogenesis induced WE43 Mg-Hydroxyapatite composites with low biodegradability and increased biocompatibility for orthopedic implant applications. J Mater Res Technol 25:4277–4298. https://doi.org/10.1016/j.jmrt.2023.06.237

El-Sayed MM, Shash AY, El-Danaf EA, Abd-Rabou M, ElSherbiny MG (2023) Impact of multi-pass friction stir alloying on the characterization of Mg based bio-ceramic nano composites. J Alloys Compd 959:170477. https://doi.org/10.1016/j.jallcom.2023.170477

Rakesh KR, Bontha S, Ramesh MR, Das M, Balla VK (2019) Laser surface melting of Mg–Zn–Dy alloy for better wettability and corrosion resistance for biodegradable implant applications. Appl Surf Sci 480:70–82. https://doi.org/10.1016/j.apsusc.2019.02.167

Gao Y, Jie M, Liu Y (2017) Mechanical properties of Al2O3 ceramic coatings prepared by plasma spraying on magnesium alloy. Surf Coat Technol 315:214–219. https://doi.org/10.1016/j.surfcoat.2017.02.026

Saber-samandari S, Alamara K, Saber-samandari S (2014) Calcium phosphate coatings: morphology, micro-structure and mechanical properties. Ceram Int 40:563–572. https://doi.org/10.1016/j.ceramint.2013.06.038

Domínguez-trujillo C, Peón E, Chicardi E, Pérez H, Rodríguez-ortiz JA, Pavón JJ (2018) Surface and coatings technology sol-gel deposition of hydroxyapatite coatings on porous titanium for biomedical applications. Surf Coat Technol 333:158–162. https://doi.org/10.1016/j.surfcoat.2017.10.079

Wang B, Li Y, Wang S, Jia F, Bian A, Wang K et al (2021) Electrodeposited dopamine/strontium-doped hydroxyapatite composite coating on pure zinc for anti-corrosion, antimicrobial and osteogenesis. Mater Sci Eng C 129:112387. https://doi.org/10.1016/j.msec.2021.112387

Rakesh KR, Bontha S, Ramesh MR, Das M, Krishna V (2019) Applied surface science laser surface melting of Mg–Zn–Dy alloy for better wettability and corrosion resistance for biodegradable implant applications. Appl Surf Sci 480:70–82. https://doi.org/10.1016/j.apsusc.2019.02.167

Rokkala U, Jana A, Bontha S, Ramesh MR, Balla VK (2021) Comparative investigation of coating and friction stir processing on mg–Zn–Dy alloy for improving antibacterial, bioactive and corrosion behaviour. Surf Coat Technol 425:127708. https://doi.org/10.1016/j.surfcoat.2021.127708

Owens DK, Wendt RC (1969) Estimation of the surface free energy of polymers. J Appl Polym Sci 13:1741–1747. https://doi.org/10.1002/app.1969.070130815

Ganesh I (2013) A review on magnesium aluminate (MgAl 2 O 4) spinel synthesis processing and applications. Int Mater Rev 58:63–112. https://doi.org/10.1179/1743280412Y.0000000001

Yang K, Shi J, Wang L, Chen Y, Liang C, Yang L et al (2022) Bacterial anti-adhesion surface design: surface patterning, roughness and wettability: a review. J Mater Sci Technol 99:82–100. https://doi.org/10.1016/j.jmst.2021.05.028

Zhang W, Zhao MC, Wang Z, Tan L, Qi Y, Yin DF et al (2022) Enhanced initial biodegradation resistance of the biomedical Mg–Cu alloy by surface nanomodification. J Magnes Alloy 11:2776–2788. https://doi.org/10.1016/j.jma.2021.12.013

Laheurte R, Darnis P, Darbois N, Cahuc O (2012) Subsurface damage distribution characterization of ground surfaces using Abbott–Firestone curves. Opt Express 20:13551–9

Fk MD, Panigrahi SK (2018) Achieving excellent superplasticity in an ultrafine-grained QE22 alloy at both high strain rate and low-temperature regimes. J Alloys Compd 747:71–82. https://doi.org/10.1016/j.jallcom.2018.02.294

Khan MF, Rokkala U (2023) Development of high strength and corrosion resistance Mg–Zn–Dy/HA–Ag composite for temporary implant applications. Mater Lett 347:134604. https://doi.org/10.1016/j.matlet.2023.134604

Ho Y-H, Vora HD, Dahotre NB (2014) Laser surface modification of AZ31B Mg alloy for bio-wettability. J Biomater Appl 29:915–928. https://doi.org/10.1177/0885328214551156

Rosales-Leal JI, Rodríguez-Valverde MA, Mazzaglia G, Ramón-Torregrosa PJ, Díaz-Rodríguez L, García-Martínez O et al (2010) Effect of roughness, wettability and morphology of engineered titanium surfaces on osteoblast-like cell adhesion. Coll Surf Physicochem Eng Asp 365:222–9. https://doi.org/10.1016/j.colsurfa.2009.12.017

Kumar SS, Hiremath SS, Ramachandran B, Muthuvijayan V (2019) Biotribology effect of surface finish on wettability and bacterial adhesion of micromachined biomaterials. Biotribology 18:100095. https://doi.org/10.1016/j.biotri.2019.100095

Edwards KJ, Rutenberg AD (2001) Microbial response to surface microtopography : the role of metabolism in localized mineral dissolution. Chem Geol 180:19–32

Taylor P, Ribeiro M, Monteiro FJ, Ferraz MP, Ribeiro M, Monteiro FJ et al (2014) Studying bacterial-material interactions infection of orthopedic implants with emphasis on bacterial adhesion process and techniques used in studying bacterial-material interactions. Biomatter 2:37–41. https://doi.org/10.4161/biom.22905

Yoda I, Koseki H, Tomita M, Shida T, Horiuchi H, Sakoda H et al (2014) Effect of surface roughness of biomaterials on Staphylococcus epidermidis adhesion. BMC Microbiol 14:1–7. https://doi.org/10.1186/s12866-014-0234-2

Ling Q, Nam T, Wu J, Seo E, Ock J (1998) Antibacterial effects of Ag-HAp thin ® lms on alumina substrates. Thin Solid Films 335:214–9.

Hashimoto M, Sasaki JI, Imazato S (2016) Investigation of the cytotoxicity of aluminum oxide nanoparticles and nanowires and their localization in L929 fibroblasts and RAW264 macrophages. J Biomed Mater Res-Part B Appl Biomater 104:241–252. https://doi.org/10.1002/jbm.b.33377

Zhang Y, Xu J, Ruan YC, Yu MK, O’Laughlin M, Wise H et al (2016) Implant-derived magnesium induces local neuronal production of CGRP to improve bone-fracture healing in rats. Nat Med 22:1160–1169. https://doi.org/10.1038/nm.4162

Blair HC, Larrouture QC, Tourkova IL, Liu L, Bian JH, Stolz DB et al (2018) Support of bone mineral deposition by regulation of pH. Am J Physiol-Cell Physiol 315:C587–C597. https://doi.org/10.1152/ajpcell.00056.2018

Zhao Q, Mahmood W, Zhu Y (2016) Synthesis of dittmarite/Mg(OH)2 composite coating on AZ31 using hydrothermal treatment. Appl Surf Sci 367:249–58. https://doi.org/10.1016/j.apsusc.2016.01.055

Shen X, Zhang Y, Ma P, Sutrisno L, Luo Z, Hu Y et al (2019) Fabrication of magnesium/zinc-metal organic framework on titanium implants to inhibit bacterial infection and promote bone regeneration. Biomater 212:1–16. https://doi.org/10.1016/j.biomaterials.2019.05.008

Chen M, Hu Y, Hou Y, Li M, Tan L, Chen M et al (2022) Magnesium/gallium-layered nanosheets on titanium implants mediate osteogenic differentiation of MSCs and osseointegration under osteoporotic condition. Chem Eng J 427:130982. https://doi.org/10.1016/j.cej.2021.130982

Gittens RA, Olivares-Navarrete R, Schwartz Z, Boyan BD (2014) Implant osseointegration and the role of microroughness and nanostructures: lessons for spine implants. Acta Biomater 10:3363–3371. https://doi.org/10.1016/j.actbio.2014.03.037

Boyan BD, Lotz EM, Schwartz Z (2017) Roughness and hydrophilicity as osteogenic biomimetic surface properties. Tissue Eng-Part A 23:1479–1489. https://doi.org/10.1089/ten.tea.2017.0048

Zhao G, Zinger O, Schwartz Z, Wieland M, Landolt D, Boyan BD (2006) Osteoblast-like cells are sensitive to submicron-scale surface structure. Clin Oral Implants Res 17:258–264. https://doi.org/10.1111/j.1600-0501.2005.01195.x

Kim M-J, Kim C-W, Lim Y-J, Heo S-J (2006) Microrough titanium surface affects biologic response in MG63 osteoblast-like cells. J Biomed Mater Res A 79:1023–1032. https://doi.org/10.1002/jbm.a.31040

Schwartz Z, Raz P, Zhao G, Barak Y, Tauber M, Yao H et al (2008) Effect of micrometer-scale roughness of the surface of Ti6Al4V pedicle screws in vitro and in vivo. J Bone Joint Surg Am 90:2485–2498. https://doi.org/10.2106/JBJS.G.00499

Petrie TA, Reyes CD, Burns KL, García AJ (2009) Simple application of fibronectin-mimetic coating enhances osseointegration of titanium implants. J Cell Mol Med 13:2602–2612. https://doi.org/10.1111/j.1582-4934.2008.00476.x

van der Flier A, Sonnenberg A (2001) Function and interactions of integrins. Cell Tissue Res 305:285–298. https://doi.org/10.1007/s004410100417

Olivares-Navarrete R, Raz P, Zhao G, Chen J, Wieland M, Cochran DL et al (2008) Integrin alpha2beta1 plays a critical role in osteoblast response to micron-scale surface structure and surface energy of titanium substrates. Proc Natl Acad Sci U S A 105:15767–15772. https://doi.org/10.1073/pnas.0805420105

Lossdörfer S, Schwartz Z, Wang L, Lohmann CH, Turner JD, Wieland M et al (2004) Microrough implant surface topographies increase osteogenesis by reducing osteoclast formation and activity. J Biomed Mater Res A 70:361–369. https://doi.org/10.1002/jbm.a.30025

Dinodi N, Shetty AN (2014) Alkyl carboxylates as efficient and green inhibitors of magnesium alloy ze41 corrosion in aqueous salt solution. Corros Sci 85:411–427. https://doi.org/10.1016/j.corsci.2014.04.052

Atrens A, Shi Z, Mehreen SU, Johnston S, Song G, Chen X et al (2020) Review of Mg alloy corrosion rates. J Magnes Alloy 8:989–998. https://doi.org/10.1016/j.jma.2020.08.002

Woodrow NS, Arterial P, Standard N (2004) Arterial blood gas analysis 18 45–52

Xu F, Luo L, **ong L, Liu Y (2020) Microstructure and corrosion behavior of ALD Al 2 O 3 film on AZ31 magnesium alloy with different surface roughness. J Magnes Alloys 8:480–92. https://doi.org/10.1016/j.jma.2019.06.003

Guo L, Zhang F, Song L, Zeng R-C, Li S-Q (2017) Corrosion resistance of ceria/polymethyltrimethoxysilane modified magnesium hydroxide coating on AZ31 magnesium alloy. Surf Coat Technol 328:121–133. https://doi.org/10.1016/j.surfcoat.2017.08.039

Acknowledgements

The authors would like to express their sincere thanks to Manufacturing Laboratory, Department of Mechanical Engineering, Department of Chemistry and Central Research Facility (CRF), National Institute of Technology, Karnataka, for providing access to microhardness, electrochemical corrosion testing, profilometer, FESEM and XRD facilities respectively.

Author information

Authors and Affiliations

Contributions

Uzwalkiran Rokkala contributed to conceptualization, methodology, validation, investigation, writing—original draft, writing—review and editing, visualization, formal analysis. Srikanth Bontha and M.R. Ramesh helped in supervision, resources, conceptualization, methodology, writing—review and editing, project administration. Vamsi Krishna Balla done supervision, conceptualization, methodology, writing—review and editing.

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Handling Editor: Maude Jimenez.

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Rokkala, U., Bontha, S., Ramesh, M.R. et al. Multi-step fabrication of bioactive Mg–Zn–Dy–AlO3/HA composites: exploring the synergistic effects of plasma spray and friction stir processing. J Mater Sci 59, 10998–11014 (2024). https://doi.org/10.1007/s10853-024-09830-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-024-09830-y