Abstract

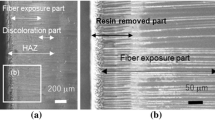

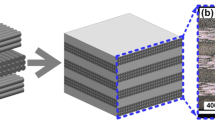

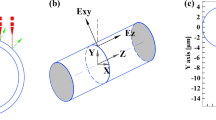

One of the effective ways to achieve drilling of Carbon fiber reinforced polymer (CFRP) materials is to use short pulse lasers. However, the existing cutting thermal damage, such as the heat-affected zone (HAZ), can weaken the CFRP mechanical properties. In this paper, a heterogeneous mesoscopic model of transient distribution of short pulse laser ablation heat flow is built to fully explore the formation and extension mechanism of thermal damage. The significant difference in laser interaction thermal effects between fibers and resin leads to the formation of HAZ with exposed fibers. The interface effect exists in the ablation process, which aggravates the matrix damage. The ablation of carbon fibers occurs within the duration of a single laser pulse, and the degree of ablation depends on the pulse energy. Under the coupling of the thermal conduction effect along the fiber axis and the thermal accumulation effect between pulses, the matrix damage extends significantly during the cooling stage. Large pulse repetition frequency increases heat accumulation between pulses and increases matrix damage. There is a new erosion mechanism in that the thermal accumulation behavior leads to the falling off of fragmented carbon fiber filaments. The accuracy of the model was verified through different pulse ablation tests, and the average error of ablation morphology is 11.28%.

Similar content being viewed by others

Data availability

The data are available from the corresponding author upon reasonable request.

References

Alam P, Mamalis D, Robert C, Floreani C, Brádaigh C (2019) The fatigue of carbon fibre reinforced plastics—a review. Compos B Eng 166:555–579

An Q, Chen J, Ming W, Chen M (2021) Machining of SiC ceramic matrix composites: a review. Chin J Aeronaut 34(4):540–567

**a HB, Tao W, Li LQ, Tan CW, Zhang KP, Ma NS (2020) Effect of laser beam models on laser welding–brazing Al to steel. Opt Laser Technol 122:105845

Guo W, Wan Z, Jia Q, Ma L, Zhang H, Tan C, Peng P (2020) Laser weldability of TWIP980 with DP980/ B1500HS/QP980 steels: microstructure and mechanical properties. Opt Laser Technol 124:105961

Li M, Li S, Yang X, Zhang Y, Liang Z (2019) Effect of lay-up configuration and processing parameters on surface quality during fiber laser cutting of CFRP laminates. Int J Adv Manuf Technol 100:623–635

Meinhard D, Haeger A, Knoblauch V (2021) Drilling induced defects on carbon fiber-reinforced thermoplastic polyamide and their effect on mechanical properties. Compos Struct 256:113138

Li M, Huang M, Jiang X, Kuo C, Yang X (2018) Study on burr occurrence and surface integrity during slot milling of multidirectional and plain woven CFRPs. Int J Adv Manuf Tech 97(1–4):163–173

Feito N, Díaz-Alvarez J, Lopez-Puente J, Miguelez MH (2018) Experimental and numerical analysis of step drill bit performance when drilling woven CFRPs. Compos Struct 184:1147–1155

Jia Z, Fu R, Niu B, Qian B, Bai Y, Wang F (2016) Novel drill structure for damage reduction in drilling CFRP composites. Int J Mach Tools Manuf 110:55–65

Ramulu M, Arola D (1993) Water jet and abrasive water jet cutting of unidirectional graphite/epoxy composite. Composites 24(4):299–308

Alberdi A, Suárez A, Artaza T, Escobar-Palafox GA, Ridgway K (2013) Composite cutting with abrasive water jet. Procedia Engineering 63:421–429

Guu YH, Hocheng H, Tai NH, Liu SY (2001) Effect of electrical discharge machining on the characteristics of carbon fiber reinforced carbon composites. J Mater Sci 36(8):2037–2043

El-Hofy MH, El-Hofy H (2019) Laser beam machining of carbon fiber reinforced composites: a review. Int J Adv Manuf Tec 101(9–12):2965–2975

Mucha P, Speker N, Weber R, Graf T (2013) Momentum and velocity of the ablated material in laser machining of carbon fiber preforms. Appl Phys A-Mater 113(2):361–366

Riveiro A, Quintero F, Lusquiños F, Del Val J, Comesaña R, Boutinguiza M, Pou J (2012) Experimental study on the CO2 laser cutting of carbon fiber reinforced plastic composite. Compos Part A-Appl S 43(8):1400–1409

Shanmugam DK, Nguyen T, Wang J (2008) A study of delamination on graphite/epoxy composites in abrasive waterjet machining. Compos Part A-Appl S 39(6):923–929

Sala G (2000) Composite degradation due to fluid absorption. Compos Part B-Eng 31(5):357–373

Yue X, Yang X, Tian J, He Z, Fan Y (2018) Thermal, mechanical and chemical material removal mechanism of carbon fiber reinforced polymers in electrical discharge machining. Int J Mach Tool and Manu 133:4–17

Habib S, Okada A (2016) Influence of electrical discharge machining parameters on cutting parameters of carbon fiber-reinforced plastic. Mach Sci Technol 20(1):99–114

Li M, Li S, Yang X (2020) The influence of machining processes on strain distribution and progressive failure characteristics when producing holes in CFRP. Compos Struct 238:111994

Stock J, Zaeh MF, Conrad M (2012) Remote laser cutting of CFRP: improvements in the cut surface. Phys Procedia 39:161–170

Takahashi K, Tsukamoto M, Masuno S, Sato Y, Yoshida H, Tsubakimoto K, Fujita H, Miyanaga N, Fujita M, Ogata H (2015) Influence of laser scanning conditions on CFRP processing with a pulsed fiber laser. J Mater Process Tech 222:110–121

Tao N, Chen G, Yu T, Li W, Fan L (2020) Dual-beam laser drilling process for thick carbon fiber reinforced plastic composites plates. Mater Process Tech 281:116590

Li W, Zhang G, Huang Y, Rong Y (2021) Drilling of CFRP plates with adjustable pulse duration fiber laser. Mater Manuf Process 36(11):1256–1263

Leone C, Genna S (2018) Heat affected zone extension in pulsed Nd:YAG laser cutting of CFRP. Compos Part B-Eng 140:174–182

Li W, Huang Y, Chen X, Zhang G, Huang Y, Rong Y, Lu Y (2021) Study on laser drilling induced defects of CFRP plates with different scanning modes based on multi-pass strategy. Opt Laser Technol 144(19):107400

Li W, Huang Y, Chen L, Chen X, Zhang G, Rong Y (2022) Effect of anisotropy on the quality of laser cutting corner of CFRP plate. ASME J Manuf Sci Eng 144(11):111003

Li ZL, Zheng HY, Lim CG, Chu PL, Li L (2010) Study on UV laser machining quality of carbon fibre reinforced composites. Compos Part A-Appl Sci Manuf 41(10):1403–1408

Li W, Zhang G, Huang Y, Rong Y (2021) UV laser high-quality drilling of CFRP plate with a new interlaced scanning mode. Compos Struct 273(11):114258

Fischer F, Romoli L, Kling R (2010) Laser-based repair of carbon fiber reinforced plastics. CIRP Ann Manuf Technol 59(1):203–206

Takahashi K, Tsukamoto M, Masuno S, Sato Y (2016) Heat conduction analysis of laser CFRP processing with IR and UV laser light. Compos Part A-Appl S 84:114–122

Leone C, Papa I, Tagliaferri F, Lopresto V (2013) Investigation of CFRP laser milling using a 30 W Q-switched Yb:YAG fiber laser: effect of process parameters on removal mechanisms and HAZ formation. Compos Part A-Appl S 55:129–142

Jiao H, Lin Z, Zhang G, Zhou J, Huang Y, Long Y (2024) Scribing of surface-braided CFRP with picosecond laser: thermal damage formation and removal mechanism analysis. Appl Phys A 130:120

Luo Y, Zhu X, Zhang W, Chang C, Gao S, Lu B, Yan X (2023) Modeling of tow-to-spot diameter ratio for laser cutting of single-layer carbon fiber–reinforced plastics (CFRP). Int J Adv Manuf Technol 127(9–10):1–14

Yang H, Liu H, Gao R, Liu X, Yu X, Song F, Liu L (2022) Numerical simulation of paint strip** on CFRP by pulsed laser. Opt Laser Technol 145:107450

Tao N, Chen G, Fan L, Wang B, Li M, Fang W (2021) Temperature-dependent material removal during pulsed laser processing of CFRP composites. Opt Laser Technol 144:107445

Xu LY, Lu JR, Li KM, Hu J (2021) Removal mechanism of CFRP by laser multi direction interaction. Opt Laser Technol 143:107281

Chai Q, Luo Y, Qian X, Zhang Y, Zhao L (2024) Investigation on ablative process of CFRP laminates under laser irradiations. Opt Laser Technol 174:110687

Weber R, Hafner M, Michalowski A, Graf T (2011) Minimum damage in CFRP laser processing. Phys Procedia 12:302–307

Romoli L, Fischer F, Kling R (2012) A study on UV laser drilling of PEEK reinforced with carbon fibers. Opt Lasers Eng 50(3):449–457

Jou J, Liebot J, Casas V (1982) Irreversible-thermodynamics process to nonequilibrium heat fluctuations. Phys Rev A 25(1):508–518

Poprawe R (2011) Tailored light 2 laser application technology. Springer Verlag Berlin and Heidelberg GmbH Co.KG, Berlin

Goldak J, Chakranarti A, Bibby M (1984) A new finite element model for welding heat sources. Metall Trans B 15(2):299–305

Li W, Rong Y, Huang Y, Chen X, Chen L, Zhang G (2023) Dimethicone-assisted interlaced scanning compound cutting for regulating thermal damage in CFRP laser cutting by synergistic suppression of coupled heat effect. Compos B Eng 266:110969

Nejad S, Srivastava R, Bellussi F, Thielemann H, Asinari P, Fasano M (2021) Nanoscale thermal properties of carbon nanotubes/epoxy composites by atomistic simulations. Int J Therm Sci 159:106588

Bellussi F, Ezquerro C, Laspalas M, Chiminelli A (2021) Effects of graphene oxidation on interaction energy and interfacial thermal conductivity of polymer nanocomposite: a molecular dynamics approach. Nanomaterials (Basel). 11(7):1709

Acknowledgements

This work is supported by the National Natural Science Foundation of China (Grant Nos. 52188102, 52375433 & 52305468), the China Postdoctoral Science Foundation (Grant No. 2023M731193) and the Major Program (JD) of Hubei Province (2023BAA015).

Author information

Authors and Affiliations

Contributions

Not applicable.

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Ethical approval

There are no experiments involving human tissue in this article.

Additional information

Handling Editor: Ghanshyam Pilania.

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Rong, Y., Chen, L., Li, W. et al. Analysis of thermal damage formation and extension mechanism in CFRP short pulse laser cutting based on an inhomogeneous mesoscopic ablation model. J Mater Sci 59, 8338–8359 (2024). https://doi.org/10.1007/s10853-024-09679-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-024-09679-1