Abstract

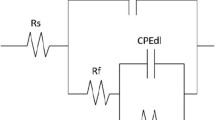

Here, we investigate the effect of high-pressure torsion (HPT), a severe plastic deformation process, on the mechanical properties, corrosion, and cytotoxicity of Mg–6Zn–0.2Ce alloy, a candidate material for bioresorbable bone implants. This alloy was processed by quasi-constrained HPT by applying a pressure of 6 GPa at room temperature for 1, 2, and 5 turns. Samples processed to two turns of HPT showed the smallest grain size, the highest strength that was approximately five times higher than the as-received coarse-grained sample and a reduction in the ductility. Electrochemical impedance spectroscopy and potentiodynamic polarization demonstrated the highest corrosion resistance for the Mg-alloy processed for two turns of HPT; however, accelerated degradation due to pitting corrosion was observed after immersion in simulated body fluid for 3 days. Nevertheless, all HPT-processed samples showed lower corrosion rates in all corrosion tests compared to their annealed counterparts. Finally, cell culture revealed good cytocompatibility without any noticeable changes in cytotoxicity following HPT processing. Overall, HPT for two turns showed enhanced strength and reduced corrosion rates without loss in cytocompatibility for the Mg–6Zn–0.2Ce alloy, making it a promising strategy to enhance the performance of the alloy as a bioresorbable orthopedic biomaterial. This work highlights the potential of HPT as a viable technique to improve the biomedical performance of Mg alloys for engineering next-generation biomedical implants.

Similar content being viewed by others

References

Pietrzak WS, Sarver D, Verstynen M (1996) Bioresorbable implants-practical considerationS. Bone 19:109–119

Williams DF (2003) Biomaterials and tissue engineering in reconstructive surgery. Sadhana 28:563–574

Tsakiris V, Tardei C, Clicinschi FM (2021) Biodegradable Mg alloys for orthopedic implants—a review-NC-ND License (http://Creativecommons.Org/Licenses/by-Nc-Nd/4.0/) Peer Review under Responsibility of Chongqing University. J Magn Alloys 9:1884–1905, https://doi.org/10.1016/j.jma.2021.06.024

Prakasam M, Locs J, Salma-Ancane K, Loca D, Largeteau A, Berzina-Cimdina L (2017) Biodegradable materials and metallic implants—a review. J Funct Biomater 8:44. https://doi.org/10.3390/jfb8040044

Kluin OS, Van der Mei HC, Busscher HJ, Neut D (2013) Biodegradable vs non-biodegradable antibiotic delivery devices in the treatment of osteomyelitis. Expert Opin Drug Deliv 10:341–351

Amini AR, Wallace JS, Nukavarapu SP (2011) Short-term and long-term effects of orthopedic biodegradable implants. J Long Term Eff Med Implants 21:93–122

Bergman C, Gray-Scott D, Chen J-J, Meacham S (2009) What is next for the dietary reference intakes for bone metabolism related nutrients beyond calcium: phosphorus, magnesium, vitamin D, and fluoride? Crit Rev Food Sci Nutr 49:136–144

Quamme GA, de Rouffignac C (2000) Epithelial magnesium transport and regulation by the kidney. Front Biosci 5:694–711. https://doi.org/10.2741/quamme

Xu L, Liu X, Sun K, Fu R, Wang G (2022) Corrosion behavior in magnesium-based alloys for biomedical applications. Materials 15:2613. https://doi.org/10.3390/ma15072613

Xu Y, Wang L, Huang M, Gensch F, Kainer KU, Hort N (2018) The effect of solid solute and precipitate phase on young’s modulus of binary Mg–RE alloys. Adv Eng Mater 20:1800271. https://doi.org/10.1002/adem.201800271

Zhang S, Zhang X, Zhao C, Li J, Song Y, **e C, Tao H, Zhang Y, He Y, Jiang Y (2010) Research on an Mg–Zn alloy as a degradable biomaterial. Acta Biomater 6:626–640

Song YL, Liu YH, Wang SH, Yu SR, Zhu XY (2007) Effect of cerium addition on microstructure and corrosion resistance of die cast AZ91 magnesium alloy. Mater Corros 58:189–192

**e F, Shen J, Song H, **e X (2018) Effects of cerium and SiC mixed particles on nanoparticle strengthening activated TIG-welded AZ31 Alloy joints. J Mater Res 33:4340–4348

Zhou H, Zeng X, Liu L, Zhang Y, Zhu Y, Ding W (2004) Effect of cerium on microstructures and mechanical properties of AZ61 wrought magnesium alloy. J Mater Sci 39:7061–7066. https://doi.org/10.1023/B:JMSC.0000047551.04037.fe

Sabat RK, Brahme AP, Mishra RK, Inal K, Suwas S (2018) Ductility enhancement in Mg-0.2% Ce alloys. Acta Mater 161:246–257

Behera M, Rajput M, Acharya S, Nadammal N, Suwas S, Chatterjee K (2021) Zinc and cerium synergistically enhance the mechanical properties, corrosion resistance, and osteogenic activity of magnesium as resorbable biomaterials. Biomed Mater 16:044109. https://doi.org/10.1088/1748-605X/ac0453

Galiyev A, Sitdikov O, Kaibyshev R (2003) Deformation behavior and controlling mechanisms for plastic flow of magnesium and magnesium alloy. Mater Trans 44:426–435

Silva CLP, Soares RB, Pereira PHR, Figueiredo RB, Lins VFC, Langdon TG (2019) The effect of high-pressure torsion on microstructure, hardness and corrosion behavior for pure magnesium and different magnesium alloys. Adv Eng Mater 21:1801081. https://doi.org/10.1002/adem.201801081

Li W, Liu X, Zheng Y, Wang W, Qiao W, Yeung KWK, Cheung KMC, Guan S, Kulyasova OB, Valiev RZ (2020) In vitro and in vivo studies on ultrafine-grained biodegradable pure Mg, Mg–Ca alloy and Mg–Sr alloy processed by high-pressure torsion. Biomater Sci 8:5071–5087. https://doi.org/10.1039/d0bm00805b

Udio C, Silva LP, Oliveira AC, Costa CGF, Figueiredo RB, De Fátima Leite M, Pereira MM, Lins VFC, Langdon TG (2017) Effect of severe plastic deformation on the biocompatibility and corrosion rate of pure magnesium. J Mater Sci 52:5992–6003. https://doi.org/10.1007/s10853-017-0835-x

Medeiros MP, Carvalho AP, Isaac A, Afonso CRM, Janeček M, Minárik P, Celis MM, Figueiredo RB (2023) Using high pressure torsion to process magnesium alloys for biological applications. J Market Res 22:3075–3084. https://doi.org/10.1016/j.jmrt.2022.12.127

Ahmadkhaniha D, Huang Y, Jaskari M, Järvenpää A, Sohi MH, Zanella C, Karjalainen LP, Langdon TG (2018) Effect of high-pressure torsion on microstructure, mechanical properties and corrosion resistance of cast pure Mg. J Mater Sci 53:16585–16597. https://doi.org/10.1007/s10853-018-2779-1

Lee H-J, Ahn B, Kawasaki M, Langdon TG (2015) Evolution in hardness and microstructure of ZK60A magnesium alloy processed by high-pressure torsion. J Mater Res Technol 4(1):18–25. https://doi.org/10.1016/j.jmrt.2014.10.015

Song D, Ma A, Jiang J, Lin P, Yang D, Fan J (2010) Corrosion behavior of equal-channel-angular-pressed pure magnesium in NaCl aqueous solution. Corros Sci 52:481–490

Zhang CZ, Zhu SJ, Wang LG, Guo RM, Yue GC, Guan SK (2016) Microstructures and degradation mechanism in simulated body fluid of biomedical Mg-Zn–Ca alloy processed by high pressure torsion. Mater Des 96:54–62. https://doi.org/10.1016/j.matdes.2016.01.072

Kim S-M, Jo J-H, Lee S-M, Kang M-H, Kim H-E, Estrin Y, Lee J-H, Lee J-W, Koh Y-H, S-m K et al (2013) Hydroxyapatite-coated magnesium implants with improved in vitro and in vivo biocorrosion, biocompatibility, and bone response. J Biomed Mater Res Part A 102:429–441. https://doi.org/10.1002/jbm.a.34718

King AD, Birbilis N, Scully JR (2014) Accurate electrochemical measurement of magnesium corrosion rates; a combined impedance, mass-loss and hydrogen collection study. Electrochim Acta 121:394–406. https://doi.org/10.1016/j.electacta.2013.12.124

Światowska J, Volovitch P, Ogle K (2010) The anodic dissolution of Mg in NaCl and Na2SO4 electrolytes by atomic emission spectroelectrochemistry. Corros Sci 52:2372–2378

Williams G, Birbilis N, McMurray HN (2013) The source of hydrogen evolved from a magnesium anode. Electrochem commun 36:1–5

Frankel GS, Samaniego A, Birbilis N (2013) Evolution of hydrogen at dissolving magnesium surfaces. Corros Sci 70:104–111

Lopes DR, Silva CLP, Soares RB, Pereira HR, Oliveira AC, Figueiredo RB, Langdon TG, Lins VFC (2019) Cytotoxicity and corrosion behavior of magnesium and magnesium alloys in Hank’s solution after processing by high-pressure torsion. Adv Eng Mater 21(8):1900391. https://doi.org/10.1002/adem.201900391

Zhilyaev AP, Langdon TG (2008) Using high-pressure torsion for metal processing: fundamentals and applications. Prog Mater Sci 53:893–979. https://doi.org/10.1016/j.pmatsci.2008.03.002

Acharya S, Panicker AG, Laxmi DV, Suwas S, Chatterjee K (2019) Study of the influence of Zr on the mechanical properties and functional response of Ti–Nb–Ta–Zr–O Alloy for orthopedic applications. Mater Des 164:107555. https://doi.org/10.1016/J.MATDES.2018.107555

Kirkland NT, Birbilis N (2014) Magnesium biomaterials: design, testing, and best practice. Springer, Berlin/Heidelberg, Germany. https://doi.org/10.1007/978-3-319-02123-2

American Society for Testing and Materials (Filadelfia, P. ASTM) (2004) G31–72: standard practice for laboratory immersion corrosion testing of metals. ASTM

Materials, AS for T. and ASTM G1–03 (2011) Standard practice for preparing, cleaning, and evaluating corrosion test specimens 2011

Figueiredo RB, Poggiali FSJ, Silva CLP, Cetlin PR, Langdon TG (2016) The influence of grain size and strain rate on the mechanical behavior of pure magnesium. J Mater Sci 51:3013–3024. https://doi.org/10.1007/S10853-015-9612-X/FIGURES/12

Bonarski BJ, Schafler E, Mingler B, Skrotzki W, Mikulowski B, Zehetbauer MJ (2008) Texture evolution of Mg during high-pressure torsion. J Mater Sci 43:7513–7518. https://doi.org/10.1007/s10853-008-2794-8

Edalati K, Yamamoto A, Horita Z, Ishihara T (2011) High-pressure torsion of pure magnesium: evolution of mechanical properties, microstructures and hydrogen storage capacity with equivalent strain. Scr Mater 64:880–883. https://doi.org/10.1016/j.scriptamat.2011.01.023

Rijal A, Singh SP, Han JK, Kawasaki M, Kumar P (2020) Effect of high-pressure torsion on hardness and electrical resistivity of commercially pure Cu. Adv Eng Mater 22:1900547. https://doi.org/10.1002/ADEM.201900547

Mungole T, Nadammal N, Dawra K, Kumar P, Kawasaki M, Langdon TG (2013) Evolution of microhardness and microstructure in a cast Al-7% Si alloy during high-pressure torsion. J Mater Sci 48:4671–4680. https://doi.org/10.1007/s10853-012-7061-3

Bazarnik P, Huang Y, Lewandowska M, Langdon TG (2015) Structural impact on the Hall–Petch relationship in an Al–5Mg alloy processed by high-pressure torsion. Mater Sci Eng A 626:9–15. https://doi.org/10.1016/J.MSEA.2014.12.027

Heczel A, Kawasaki M, Lábár JL, Jang J-I, Langdon TG, Gubicza J (2017) Defect structure and hardness in nanocrystalline CoCrFeMnNi high-entropy alloy processed by high-pressure torsion. J Alloys CompD 711:143–154. https://doi.org/10.1016/j.jallcom.2017.03.352

Kumar P, Kawasaki M, Langdon TG (2016) Review: overcoming the paradox of strength and ductility in ultrafine-grained materials at low temperatures. J Mater Sci 51:7–18. https://doi.org/10.1007/s10853-015-9143-5

Horky J, Ghaffar A, Werbach K, Mingler B, Pogatscher S, Schäublin R, Setman D, Uggowitzer PJ, Löffler JF, Zehetbauer MJ (2019) Exceptional strengthening of biodegradable Mg–Zn–Ca alloys through high pressure torsion and subsequent heat treatment. Materials 12:2460. https://doi.org/10.3390/ma12152460

Zhao C, Li Z, Shi J, Chen X, Tu T, Luo Z, Cheng R, Atrens A, Pan F (2019) Strain hardening behavior of Mg–Y alloys after extrusion process. J Magn Alloys 7:672–680. https://doi.org/10.1016/j.jma.2019.09.004

**ong H, Liang Z, Wang Z, Qin C, Zhao W, Yu H (2018) Mechanical properties and degradation behavior of Mg(100–7x)Zn6xYx(x = 0.2, 0.4, 0.6, 0.8) alloys. Metals (Basel) 8:261. https://doi.org/10.3390/met8040261

Singh IB, Singh M, Das S (2015) A comparative corrosion behavior of Mg, AZ31 and AZ91 alloys in 3.5% NaCl solution. J Magn Alloys 3(2):142–148. https://doi.org/10.1016/j.jma.2015.02.004

Makar GL, Kruger J (1993) Corrosion of magnesium. Int Mater Rev 38:138–153. https://doi.org/10.1179/imr.1993.38.3.138

Srinivasan A, Kwang A, Shin S, Rajendran N (2014) Dynamic electrochemical impedance spectroscopy (DEIS) studies of AZ31 magnesium alloy in simulated body fluid solution. RSC Adv Commun 4(53):27791–27795. https://doi.org/10.1039/c4ra02432j

Kirkland NT, Birbilis N, Staiger MP (2012) Assessing the corrosion of biodegradable magnesium implants: a critical review of current methodologies and their limitations. Acta Biomater 8(3):925–936. https://doi.org/10.1016/j.actbio.2011.11.014

Gerashi E, Alizadeh R, Langdon TG (2022) Effect of crystallographic texture and twinning on the corrosion behavior of Mg alloys: a review. J Magn Alloys 10:313–325. https://doi.org/10.1016/j.jma.2021.09.009

Liu J, Han E, Song Y, Shan D (2018) Effect of twins on the corrosion behavior of Mg–5Y–7Gd–0.5Zr Mg alloy. J Alloys Compd 757:356–363. https://doi.org/10.1016/j.jallcom.2018.05.105

Iso E(1999) Biological evaluation of medical devices-Part 5: tests for cytotoxicity: in vitro methods. German version EN ISO, pp 10993–10995

Gonzalez J, Hou RQ, Nidadavolu EPS, Willumeit-Römer R, Feyerabend F (2018) Magnesium degradation under physiological conditions-best practice. Bioact Mater 3:174–185

Mackenzie LWF, Pekguleryuz MO (2008) The recrystallization and texture of magnesium–zinc–cerium alloys. Scr Mater 59:665–668

Song G-L, Mishra R, Xu Z (2010) Crystallographic orientation and electrochemical activity of AZ31 Mg alloy. Electrochem Commun 12(8):1009–1012. https://doi.org/10.1016/j.elecom.2010.05.011

**n R, Li B, Li L, Liu Q (2011) Influence of texture on corrosion rate of AZ31 Mg alloy in 3.5 wt% NaCl. Mater Des 32:4548–4552. https://doi.org/10.1016/j.matdes.2011.04.031

Argade GR, Panigrahi SK, Mishra RS (2012) Effects of grain size on the corrosion resistance of wrought magnesium alloys containing neodymium. Corros Sci 58:145–151. https://doi.org/10.1016/j.corsci.2012.01.021

Patel V, Li W, Andersson J, Li N (2022) Enhancing grain refinement and corrosion behavior in AZ31B magnesium alloy via stationary shoulder friction stir processing. J Mater Res Technol 17:3150–3156. https://doi.org/10.1016/j.jmrt.2022.02.059

Pei Y, Gui Y, Huang T, Chen F, Guo J, Zhong S, Song Z (2020) Microstructure and corrosion behaviors of AZ63 magnesium alloy fabricated by accumulative roll bonding process. Mater Res Express 7:66525. https://doi.org/10.1088/2053-1591/ab9c61

Torbati-Sarraf H, Torbati-Sarraf SA, Poursaee A, Langdon TG (2019) Electrochemical behavior of a magnesium ZK60 alloy processed by high-pressure torsion. Corros Sci 154:90–100. https://doi.org/10.1016/j.corsci.2019.04.006

Acknowledgements

The authors thank the Indian Institute of Science, Bangalore, for the financial support made available under the REDA program. PK would also like to thank the Indian National Academy of Engineering for the financial support made available under its Abdul Kalam Technology Innovation National Fellowship program. KC acknowledges partial support for this work from the Indo-French Centre for the Promotion of Advanced Research (CEFIPRA, project number 6508-L). The authors thank Professor Satyam Suwas of the Department of Materials Engineering, Indian Institute of Science, Bangalore, for his generous gift of the alloy samples. The authors would like to acknowledge the National Characterization Facility at the Center of Nanoscience and Engineering, Indian Institute of Science, Bangalore, and the Advance Center of Microscopy and Micro-Analysis at the Indian Institute of Science, Bangalore, for help in microstructural characterization.

Author information

Authors and Affiliations

Corresponding authors

Additional information

Handling Editor: Megumi Kawasaki.

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Upadhayay, L., Nilawar, S., Kumar, C. et al. Effect of processing Mg–6Zn–0.2Ce through high-pressure torsion on its use as a biomaterial. J Mater Sci 59, 5872–5890 (2024). https://doi.org/10.1007/s10853-024-09460-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-024-09460-4