Abstract

The nonequilibrium statistical thermodynamics framework for thermally activated dislocation ensembles introduced in Parts 1 and 2 is applied to interpret and explain the fraction of plastic work done by the external applied stress that is dissipated as heat, the so-called Taylor–Quinney coefficient, for both pure metals and complex alloys. Important roles played by internal stresses and anelastic deformation are discussed for certain alloys, leading to their very low fraction of plastic work converted to heat. Conditions for the formation and development of new configurational subsystems are outlined and discussed, including the key role played by transitional or accommodational subsystems associated with interface regions between adjacent configurational subsystems with mismatch of reaction enthalpy. Size effects are attributed to decreased likelihood of access to energetically favorable accommodational configurations of dislocations in these transitional subsystems as a function of increased surface area-to-volume ratio, rather than the more common attribution to geometrically necessary dislocations or pileups. Generalized normality is discussed in terms of the requirement that post reaction glide should have the same thermodynamic driving force as that driving the dislocation through the saddle point of the reaction pathway. Noteworthy exceptions are considered based on physical mechanisms. It is argued that although the maximal intrinsic entropy production (MEP) rate heuristic cannot be rigorously proven, the Jaynesian approach of maximum information entropy change for each increment of nonequilibrium evolution is physically consistent with that of maximal intrinsic entropy production for a statistically representative set of dislocation barriers and subsystems. This consistency emerges from the increasing number density of reactions as the degree of correlation of enthalpy barriers increases among subsystems (with associated constrained local equilibrium states), which manifests corresponding increase of the configurational entropy change of pending reactions; the latter serves as a proxy for thermal dissipation associated with post reaction saddle point dynamic reconfiguration and extended glide of dislocations. Implications are discussed for both the bottom-up construction of ensemble intrinsic entropy production and the top-down construction which imposes MEP with constraints. Applicability of the Meyer–Neldel Rule for enthalpy–entropy compensation for dislocation reactions is considered at the ensemble level; it is argued to apply only under scenarios with strongly stress-assisted thermally activated reactions and for high degree of correlation of enthalpy barriers among subsystems. Certain contrasts are drawn between the present statistical thermodynamics framework and contemporary theories that emphasize the role of configurational entropy of dislocations. We close with discussion of utility of atomistics and discrete dislocation modeling methods in addressing some key outstanding issues to advance understanding, along with potentially fruitful roles for data science and machine learning.

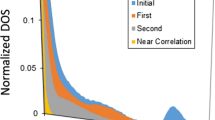

Reproduced from Fig. 3.37 of [5]

Similar content being viewed by others

Data availability

Not applicable.

Code availability

Not applicable.

References

Rittel D, Zhang LH, Osovski S (2017) The dependence of the Taylor-Quinney coefficient on the dynamic loading mode. J Mech Phys Solids 107:96–114. https://doi.org/10.1016/j.jmps.2017.06.016

Lemaitre J, Chaboche JL (1990) Mechanics of solid materials. Cambridge University Press, Cambridge, UK

Chaboche JL (1993) Cyclic viscoplastic constitutive equations, part I: a thermodynamically consistent formulation. ASME J Appl Mech 60:813–821. https://doi.org/10.1115/1.2900988

Chaboche JL (1993) Cyclic viscoplastic constitutive equations, part II: stored energy—comparison between models and experiments. ASME J Appl Mech 60:822–828. https://doi.org/10.1115/1.2900990

Smith JL (2019) Full-field measurement of the Taylor-Quinney coefficient in tension tests of Ti-6Al-4V, Aluminum 2024-T351, and Inconel 718 at various strain rates. https://rave.ohiolink.edu/etdc/view?acc_num=osu1546452653747728Dissertation. Accessed 13 July 2023.

Rollett AG, Kocks UCF (1993) A review of the stages of work hardening. Solid State Phenomena. Online: 1993–09–30 ISSN: 1662–9779, vols 35–36, pp 1–18. Trans Tech Publications Ltd, Switzerland. https://doi.org/10.4028/www.scientific.net/SSP.35-36.1

Zepeda-Ruiz LA, Stukowski A, Oppelstrup T, Bertin N, Freitas R, Bulatov V (2021) Atomistic insights into metal hardening. Nat Mater 20:315–320. https://doi.org/10.1038/s41563-020-00815-1

Feaugas X (1999) On the origin of the tensile flow stress in the Stainless Steel AISI 316L at 300 K: back stress and effective stress. Acta Mater 47(13):3617–3632. https://doi.org/10.1016/S1359-6454(99)00222-0

Soares GC, Hokka M (2021) The Taylor-Quinney coefficients and strain hardening of commercially pure titanium, iron, copper, and tin in high rate compression. Int J Impact Eng 156:103940. https://doi.org/10.1016/j.ijimpeng.2021.103940

Tanner AB (1998) Modeling Temperature and Strain Rate History Effects in OFHC Cu. https://apps.dtic.mil/sti/pdfs/ADA345850.pdf. Accessed July 12, 2023 Dissertation

Lea LJ, Jardine AP (2018) Characterisation of high rate plasticity in the uniaxial deformation of high purity copper at elevated temperatures. Int J Plast 102:41–52. https://doi.org/10.1016/j.ijplas.2017.11.006

Follansbee PS, Kocks UF (1988) A constitutive description of the deformation of copper based on the use of the mechanical threshold stress as an ISV. Acta Metall 36(1):81–93. https://doi.org/10.1016/0001-6160(88)90030-2

Kattoura M, Shehadeh MA (2014) On the ultra-high-strain rate shock deformation in copper single crystals: multiscale dislocation dynamics simulations. Philos Mag Lett 94(7):415–423.https://doi.org/10.1080/09500839.2014.920540.

Morishige T, Hirata T, Uesugi T, Takigawa Y, Tsujikawa M, Higashi K (2011) Effect of Mg content on the minimum grain size of Al–Mg alloys obtained by friction stir processing. Scripta Mater 64(4):355–358. https://doi.org/10.1016/j.scriptamat.2010.10.033

Huang A, Fensin SJ, Meyers MA (2023) Strain-rate effects and dynamic behavior of high entropy alloys. J Market Res 22:307–347. https://doi.org/10.1016/j.jmrt.2022.11.057

Agius D, Kourousis KI, Wallbrink C, Hu W, Wang CH, Dafalias YF (2017) Aluminum Alloy 7075 ratcheting and plastic shakedown evaluation with the multiplicative Armstrong-Frederick model. AIAA J 55(7):2461–2470. https://doi.org/10.2514/1.J055833

Chiem CY, Duffy J (1983) Strain rate history effects and observations of dislocation substructure in aluminum single crystals following dynamic deformation. Mater Sci Eng 57(2):233–247. https://doi.org/10.1016/0025-5416(83)90213-6

Varga J, Kingstedt OT (2021) An investigation of the plastic work to heat conversion of wrought and laser powder bed fusion manufactured Inconel 718. Addit Manuf 46:102179. https://doi.org/10.1016/j.addma.2021.102179

Zubelewicz A (2019) Century-long Taylor-Quinney interpretation of plasticity-Induced heating reexamined. Sci Rep 9:9088. https://doi.org/10.1038/s41598-019-45533-0

Liu ZK, Li B, Lin H (2019) Multiscale entropy and its implications to critical phenomena, emergent behaviors, and information. J Phase Equilib Diffus 40(4):508–521. https://doi.org/10.1007/s11669-019-00736-w

Liu ZK, Wang Y, Shang SL (2022) Zentropy theory for positive and negative thermal expansion. J Phase Equilib Diffus 43:598–605. https://doi.org/10.1007/s11669-022-00942-z

Meyers MA, Ashworth E (1982) A model for the effect of grain size on yield stress of metals. Phil Mag A 46(5):737–759. https://doi.org/10.1080/01418618208236928

Berdichevsky VL (2006) On thermodynamics of crystal plasticity. Scr Mater 54:711–716. https://doi.org/10.1016/j.scriptamat.2005.10.027

Berdichevsky VL (2019) Beyond classical thermodynamics: dislocation-mediated plasticity. J Mech Phys Solids 129:83–118. https://doi.org/10.1016/j.jmps.2019.04.014

Fu HH, Benson DJ, Meyers MA (2004) Computational description of nanocrystalline deformation based on crystal plasticity. Acta Mater 52:4413–4425. https://doi.org/10.1016/j.actamat.2004.05.036

Busso EP, Meissonnier FT, O’Dowd NP (2000) Gradient-dependent deformation of two-phase single crystals. J Mech Phys Solids 48:2333–2361. https://doi.org/10.1016/S0022-5096(00)00006-5

Horstemeyer MF (2009) Multiscale modeling: a review. In: Leszczynski J, Shukla MK (eds) Practical aspects of computational chemistry. Springer Science + Business Media B.V., Ch 4, pp. 87–135. https://doi.org/10.1007/978-90-481-2687-3_4

Gerberich WW, Tymiak NI, Grunlan JC, Horstemeyer MF, Baskes MI (2002) Interpretations of indentation size effects. ASME J Appl Mech 69(4):433–442. https://doi.org/10.1115/1.1469004

Horstemeyer MF, Baskes MI, Plimpton SJ (2001) Length scale and time scale effects on the plastic flow of fcc metals. Acta mater 49:4363–4374. https://doi.org/10.1016/S1359-6454(01)00149-5

Di Leo CV, Rimoli JJ (2019) New perspectives on the grain-size dependent yield strength of polycrystalline metals. Scripta Mater 166:149–153. https://doi.org/10.1016/j.scriptamat.2019.03.019

Li Y, Bushby AJ, Dunstan DJ (2016) The Hall–Petch effect as a manifestation of the general size effect. Proc R Soc A 472:20150890. https://doi.org/10.1098/rspa.2015.0890

Mesarovic SD, Forest S, Jaric JP (2015) Size-dependent energy in crystal plasticity and continuum dislocation models. Proc R Soc A 471:20140868. https://doi.org/10.1098/rspa.2014.0868

Hua F, Liu D, Li Y, He Y, Dunstan DJ (2021) On energetic and dissipative gradient effects within higher-order strain gradient plasticity: size effect, passivation effect, and Bauschinger effect. Int J Plast 141:102994. https://doi.org/10.1016/j.ijplas.2021.102994

Aghababaei R, Joshi SP, Reddy JN (2011) Nonlocal continuum crystal plasticity with internal residual stresses. J Mech Phys Solids 59:713–731. https://doi.org/10.1016/j.jmps.2010.11.003

Sendrowicz A, Myhre AO, Yasnikov IS, Vinogradov A (2022) Stored and dissipated energy of plastic deformation revisited from the viewpoint of dislocation kinetics modelling approach. Acta Mater 237:118190. https://doi.org/10.1016/j.actamat.2022.118190

Yang Z, Papanikolaou S, Reid ACE, Liao, WK, Choudhary AN, Campbell, C, Agrawal A (2020) Learning to predict crystal plasticity at the nanoscale: deep residual networks and size effects in uniaxial compression discrete dislocation simulations. Sci Rep 10:8262. https://doi.org/10.1038/s41598-020-65157-z

Mayeur JR, McDowell DL (2015) Micropolar crystal plasticity simulations of particle strengthening. Model Simul Mater Sci Eng 23(6):065007. https://doi.org/10.1088/0965-0393/23/6/065007

Mesarovic SD (2005) Energy, configurational forces and characteristic lengths associated with the continuum description of geometrically necessary dislocations. Int J Plast 21:1855–1889. https://doi.org/10.1016/j.ijplas.2004.09.002

Abu Al-Rub RK, Voyiadjis GZ (2006) A physically based gradient plasticity theory. Int J Plasticity 22:654–684. https://doi.org/10.1016/j.ijplas.2005.04.010

Kubin LP (1993) Dislocation patterning. In: Cahn RW, Haasen P, Kramer EJ (eds) Materials science and technology, John Wiley, Hoboken, NJ, pp 137–190

Molinari A, Ravichandran G (2005) Constitutive modeling of high-strain-rate deformation in metals based on the evolution of an effective microstructural length. Mech Mater 37(7):737–752. https://doi.org/10.1016/j.mechmat.2004.07.005

Hughes DA, Hansen N (1997) High angle boundaries formed by grain subdivision mechanisms. Acta Mater 45(9):3871–3886. https://doi.org/10.1016/S1359-6454(97)00027-X

Butler GC, McDowell DL (1998) Polycrystal constraint and grain subdivision. Int J Plast 14(8):703–717. https://doi.org/10.1016/S0749-6419(98)00018-7

Horstemeyer MF, McDowell DL (1998) Modeling effects of dislocation substructure in polycrystal elastoviscoplasticity. Mech Mater 27:145–163. https://doi.org/10.1016/S0167-6636(97)00037-9

McGinty RD, McDowell DL (1999) Multiscale polycrystal plasticity. ASME J Eng Mater Technol 121:203–209. https://doi.org/10.1115/1.2812367

Tsekenis G, Goldenfeld N, Dahmen KA (2011) Dislocations jam at any density. PRL 106:105501. https://doi.org/10.1103/PhysRevLett.106.105501

Wang J, Misra A (2011) An overview of interface-dominated deformation mechanisms in metallic multilayers. Curr Opin Solid State Mater Sci 15:20–28. https://doi.org/10.1016/j.cossms.2010.09.002

Cherkaoui M, Capolungo L (2009) Atomistic and continuum modeling of nanocrystalline materials. Springer Series in Materials Science 112, Springer-Verlag US.

Rice JR (1971) Inelastic constitutive relations for solids: an internal-variable theory and its application to metal plasticity. J Mech Phys Solids 9:433–455. https://doi.org/10.1016/0022-5096(71)90010-X

Rice JR (1975) Continuum mechanics and thermodynamics of plasticity in relation to microscale deformation mechanisms. Argon AS (ed) Constitutive equations in plasticity. MIT Press, Cambridge, MA, pp 23–79

Yang Q, Chen X, Zhou WY (2005) Relationship between normality structure and orthogonality condition. Mech Res Commun 32(5):582–589. https://doi.org/10.1016/j.mechrescom.2005.01.010

Yang Q, Chen X, Zhou WY (2006) On multiscale significance of Rice’s normality structure. Mech Res Commun 33(5):667–673. https://doi.org/10.1016/j.mechrescom.2006.01.003

Meric L, Poubanne P, Cailletaud G (1991) Single crystal modeling for structural calculations: part 1 - model presentation. ASME J Eng Mater Technol 113(1):162–170. https://doi.org/10.1115/1.2903374

Rao S, Dimiduk D, Parthasarathy T, Uchic M, Woodward C (2013) Atomistic simulations of surface cross-slip nucleation in face-centered cubic nickel and copper. Acta Mater 61:2500–2508. https://doi.org/10.1016/j.actamat.2013.01.026

Rao S, Dimiduk D, El-Awady J, Parthasarathy T, Uchic M, Woodward C (2015) Screw dislocation cross slip at cross-slip plane jogs and screw dipole annihilation in fcc Cu and Ni investigated via atomistic simulations. Acta Mater 101:10–15. https://doi.org/10.1016/j.actamat.2015.08.070

Groger R, Vitek V (2007) Explanation of the discrepancy between the measured and atomistically calculated yield stresses in body-centred cubic metals. Philos Mag Lett 87:113–120. https://doi.org/10.1080/09500830601158781

Patra A, Zhu T, McDowell DL (2014) Constitutive equations for modeling non-Schmid effects in single crystal bcc-Fe at low and ambient temperatures. Int J Plasticity 59:1–14. https://doi.org/10.1016/j.ijplas.2014.03.016

Mayeur J, McDowell DL (2007) A three-dimensional crystal plasticity model for duplex Ti-6Al-4V. Int J Plast 23(9):1457–1485. https://doi.org/10.1016/j.ijplas.2006.11.006

Racherla V, Bassani JL (2007) Strain burst phenomena in the necking of a sheet that deforms by non-associated plastic flow. Modell Simul Mater Sci Eng 15:S297–S311. https://doi.org/10.1088/0965-0393/15/1/S23

Narayanan S, McDowell DL, Zhu T (2014) Crystal plasticity model for bcc iron atomistically informed by kinetics of correlated kinkpair nucleation on screw dislocation. J Mech Phys Solids 65:54–68. https://doi.org/10.1016/j.jmps.2014.01.004

McDowell DL (2008) Viscoplasticity of heterogeneous metallic materials. Mater Sci Eng R Rep 62(3):67–123. https://doi.org/10.1016/j.mser.2008.04.003

Barlat F, Brem JC, Yoon JW, Chung K, Dick RE, Lege DJ, Pourboghrat F (2003) Plane stress yield function for aluminum alloy sheets—part 1: theory. Int J Plast 19(9):1297–1319. https://doi.org/10.1016/S0749-6419(02)00019-0

Park HS, Barlat F, Lee SY (2023) Comparison of anisotropic yield functions and calibrations for accurate thickness prediction in hole expansion test. J Mater Process Technol 319:118070. https://doi.org/10.1016/j.jmatprotec.2023.118070

Hashiguchi K (1989) Subloading surface model in unconventional plasticity. Int J Solids Struct 25(8):917–945. https://doi.org/10.1016/0020-7683(89)90038-3

McDowell DL (1999) Non-associative aspects of multiscale evolutionary phenomena. In: Picu RC, Krempl E (eds) Proceedings of the 4th international conference on constitutive laws for engineering materials, pp 54–57

Lacy TE, McDowell DL, Talreja R (1999) Gradient concepts for evolution of damage. Mech Mater 31:831–860. https://doi.org/10.1016/S0167-6636(99)00029-0

McDowell DL (1999) Damage mechanics in metal fatigue: a discriminating perspective. Int J Damage Mech 8(4):377–403. https://doi.org/10.1177/105678959900800406

Ostoja-Starzewski M (2005) Scale effects in plasticity of random media: status and challenges. Int J Plasticity 21:1119–1160. https://doi.org/10.1016/j.ijplas.2004.06.008

Uchic MD, Dimiduk DM, Florando JN, Nix WD (2004) Sample dimensions influence strength and crystal plasticity. Science 305:986–989. https://doi.org/10.1126/science.1098993

Ryu I, Nix WD, Cai W (2013) Plasticity of bcc micropillars controlled by competition between dislocation multiplication and depletion. Acta Mater 61:3233–3241. https://doi.org/10.1016/j.actamat.2013.02.011

Xu S, **ong L, Chen Y, McDowell DL (2017) Comparing EAM potentials to model slip transfer of sequential mixed character dislocations across two symmetric tilt grain boundaries in Ni. JOM 69(5):814–821. https://doi.org/10.1007/s11837-017-2302-1

Han J, Srolovitz DJ, Salvalaglio M (2022) Disconnection-mediated migration of interfaces in microstructures: I. continuum model. Acta Mater 227:117178. https://doi.org/10.1016/j.actamat.2021.117178

Jaynes ET (1957) Information theory and statistical mechanics. Phys Rev 106:620–630. https://doi.org/10.1103/PhysRev.106.620

Jaynes ET (1957) Information theory and statistical mechanics. II Phys Rev 108:171–190. https://doi.org/10.1103/PhysRev.108.171

Jaynes ET (1980) The minimum entropy production principle. Ann Rev Phys Chem 31:579–601. https://doi.org/10.1146/annurev.pc.31.100180.003051

Dewar RC (2009) Maximum entropy production as an inference algorithm that translates physical assumptions into macroscopic predictions: don’t shoot the messenger. Entropy 11:931–944. https://doi.org/10.3390/e11040931

Ross J, Corlan AD, Müller SC (2012) Proposed principles of maximum local entropy production. J Phys Chem B 116(27):7858–7865. https://doi.org/10.1021/jp302088y

Ziegler H (1977) An introduction to thermomechanics. North-Holland, Amsterdam

Ziegler H (1963) Some extremum principles in irreversible thermodynamics with applications to continuum mechanics. In: Sneddon IN, Hill R (eds) Progress in solid mechanics. North-Holland, Amsterdam, The Netherlands, pp 92–193

Ziegler H, Wehrli C (1987) On a principle of maximal rate of entropy production. J Non-Equilib Thermodyn 12:229–243. https://doi.org/10.1515/jnet.1987.12.3.229

Hackl K, Fischer FD (2008) On the relation between the principle of maximum dissipation and inelastic evolution given by dissipation potentials. Proc R Soc A 464:117–132. https://doi.org/10.1098/rspa.2007.0086

Hackl K, Fischer FD, Svoboda J (2011) A study on the principle of maximum dissipation for coupled and non-coupled non-isothermal processes in materials. Proc R Soc A 467:1186–1196. https://doi.org/10.1098/rspa.2011.0015

Hanel R, Thurner S, Gell-Mann M (2014) How multiplicity determines entropy and the derivation of the maximum entropy principle for complex systems. Proc Natl Acad Sci 111(19):6905–6910. https://doi.org/10.1073/pnas.1406071111

Hackl K, Fischer FD, Zickler GA, Svoboda J (2020) Are Onsager’s reciprocal relations necessary to apply thermodynamic extremal principles? J Mech Phys Solids 135:103780. https://doi.org/10.1016/j.jmps.2019.103780

Svoboda J, Fischer FD, McDowell DL (2012) Derivation of the phase field equations from the thermodynamic extremal principle. Acta Mater 60(1):396–406. https://doi.org/10.1016/j.actamat.2011.09.044

Gurtin ME (1996) Generalized Ginzburg-Landau and Cahn-Hilliard equations based on a microforce balance. Phys D 92:178–192. https://doi.org/10.1016/0167-2789(95)00173-5

Venkatraman A, McDowell DL, Kalidindi SR (2022) Bayesian analysis of parametric uncertainties and model form probabilities of two different crystal plasticity models of lamellar grains in α+β titanium alloys. Int J Plasticity 124:103289. https://doi.org/10.1016/j.ijplas.2022.103289

Venkatraman A, Mohan S, Joseph VR, McDowell DL, Kalidindi SR (2023) A new framework for assessing the effect of the α-β phase boundary on crystal plasticity modelling of lamellar grains in α+β titanium alloys. Modell Simul Mater Sci Eng 31:044001. https://doi.org/10.1088/1361-651X/accdf4

Meyer W, Neldel H (1937) Relation between the energy constant and the quantity constant in the conductivity–temperature formula of oxide semiconductors. Z Tech Phys 12:588

Esteban-Manzanares G, Santos-Güemes R, Papadimitriou I, Martínez E, LLorca J, (2020) Influence of the stress state on the cross-slip free energy barrier in Al: an atomistic investigation. Acta Mater 184:109–119. https://doi.org/10.1016/j.actamat.2019.10.055

Sursaeva VG, Protasova SG, Straumal BB (2001) Meyer-Neldel rule for the kinetic properties of grain and interphase boundaries. Defect and diffusion forum, vols 192–193, Scitec Publications, Switzerland, pp 15–26

Saroukhani S, Nguyen LD, Leung KWK, Singh CV, Warner DH (2016) Harnessing atomistic simulations to predict the rate at which dislocations overcome obstacles. J Mech Phys Solids 90:203–214. https://doi.org/10.1016/j.jmps.2016.02.016

Dyre JC (1986) A phenomenological model for the Meyer-Neldel rule. J Phys C Solid State Phys 19:5655–5664. https://doi.org/10.1088/0022-3719/19/28/016

Sapunov VN, Saveljev EA, Voronov MS, Valtiner M, Linert W (2021) The basic theorem of temperature-dependent processes. Thermo 1:45–60. https://doi.org/10.3390/thermo1010004

Sharpa TA, Thomas SL, Cubuk ED, Schoenholz SS, Srolovitz DJ, Liu AJ (2018) Machine learning determination of atomic dynamics at grain boundaries. PNAS 114(43):10943–10947. https://doi.org/10.1073/pnas.1807176115

Langer JS, Bouchbinder E, Lookman T (2010) Thermodynamic theory of dislocation-mediated plasticity. Acta Mater 58:3718–3732. https://doi.org/10.1016/j.actamat.2010.03.009

Langer JS (2019) Statistical thermodynamics of crystal plasticity. J Stat Phys 175:531–541. https://doi.org/10.1007/s10955-019-02221-7

Langer JS (2016) Thermal effects in dislocation theory. Phys Rev E 94:063004. https://doi.org/10.1103/PhysRevE.94.063004

Langer JS (2015) Statistical thermodynamics of strain hardening in polycrystalline solids. Phys Rev E 92:032125. https://doi.org/10.1103/PhysRevE.92.032125

Le KC, Tran TM, Langer JS (2017) Thermodynamic dislocation theory of high-temperature deformation in aluminum and steel. Phys Rev E 96:013004. https://doi.org/10.1103/PhysRevE.96.013004

Langer JS (2017) Thermodynamic theory of dislocation-enabled plasticity. Phys Rev E 96:053005. https://doi.org/10.1103/PhysRevE.96.053005

Le KC (2018) Thermodynamic dislocation theory for non-uniform plastic deformations. J Mech Phys Solids 111:157–169. https://doi.org/10.1016/j.jmps.2017.10.022

Piao Y (2019) Thermodynamic dislocation theory and its applications. https://d-nb.info/1204258287/34. Accessed 13 July 2023 Dissertation

Vilar JJG, Rubi JM (2001) Thermodynamics “beyond” local equilibrium. PNAS 98(20):11081–11084. https://doi.org/10.1073/pnas.191360398

Needleman A (2023) Discrete defect plasticity and implications for dissipation. Eur J Mech A Solids 100:105002. https://doi.org/10.1016/j.euromechsol.2023.105002

Prigogine I (1947) Etude Thermodynamique des Phénoménes Irréversibles. Desoer, Liége

Sobie C, McDowell DL, Martinez E, Capolungo L (2017) Thermal activation of dislocations in large scale obstacle bypass. J Mech Phys Solids 105:150–160. https://doi.org/10.1016/j.jmps.2017.05.003

Zhang Y, Ding K, Gu W, Chen W, Wang M, El-Awady J, McDowell DL, Zhu T (2022) Modeling of microscale internal stresses in additively manufactured stainless steel. Model Simul Mater Sci Eng 30:074001. https://doi.org/10.1088/1361-651X/ac8698

Benzerga AA, Bréchet Y, Needleman A, Van der Giessen E (2005) The stored energy of cold work: predictions from discrete dislocation plasticity. Acta Mater 53(18):4765–4779. https://doi.org/10.1016/j.actamat.2005.07.011

Benzerga AA, Shaver NF (2006) Scale dependence of mechanical properties of single crystals under uniform deformation. Scripta Mater 54:1937–1941. https://doi.org/10.1016/j.scriptamat.2006.02.003

**a S, El-Azab A (2015) Computational modelling of mesoscale dislocation patterning and plastic deformation of single crystals. Modell Simul Mater Sci Eng 23(5):055009. https://doi.org/10.1088/0965-0393/23/5/055009

El-Azab A, Po G (2020) Continuum dislocation dynamics: classical theory and contemporary models. In: Andreoni W, Yip S (eds) Handbook of materials modeling. Springer, Cham. https://doi.org/10.1007/978-3-319-44677-6_18

Hochrainer T, Sandfeld S, Zaiser M, Gumbsch P (2014) Continuum dislocation dynamics: towards a physical theory of crystal plasticity. J Mech Phys Solids 63:167–178. https://doi.org/10.1016/j.jmps.2013.09.012

Sudmans M, Stricker M, Weygand D, Hochrainer T, Schulz K (2019) Dislocation multiplication by cross-slip and glissile reaction in a dislocation based continuum formulation of crystal plasticity. J Mech Phys Solids 132:103695. https://doi.org/10.1016/j.jmps.2019.103695

Stricker M, Sudmans M, Schulz K, Hochrainer T, Weygand D (2018) Dislocation multiplication in Stage II deformation of fcc multi-slip single crystals. J Mech Phys Solids 119:319–333. https://doi.org/10.1016/j.jmps.2018.07.003

Austin RA, McDowell DL (2011) A dislocation-based constitutive model for viscoplastic deformation of fcc metals at very high strain rates. Int J Plast 27(1):1–24. https://doi.org/10.1016/j.ijplas.2010.03.002

Austin RA, McDowell DL (2012) Parameterization of a rate-dependent model of shock-induced plasticity for copper, nickel and aluminum. Int J Plast 32–33:134–154. https://doi.org/10.1016/j.ijplas.2011.11.002

Kositski R, Mordehai D (2021) Employing molecular dynamics to shed light on the microstructural origins of the Taylor-Quinney coefficient. Acta Mater 205:116511. https://doi.org/10.1016/j.actamat.2020.116511

Henkelman G, Uberuaga BP, Jonsson H (2000) A climbing image nudged elastic band method for finding saddle points and minimum energy paths. J Chem Phys 113:9901–9904. https://doi.org/10.1063/1.1329672

Zhu T, Li J, Yip S (2013) Atomistic reaction pathway sampling: the nudged elastic band method and nanomechanics applications. In: Espinosa HD, Bao G (eds) Nano and cell mechanics: fundamentals and frontiers, Vol1, Wiley, Chichester, West Sussex, Chapter 12

Wang Y, Li J (2010) Phase field modeling of defects and deformation. Acta Mater 58(4):1212–1235. https://doi.org/10.1016/j.actamat.2009.10.041

Shen C, Wang Y (2003) Phase field model of dislocation network. Acta Mater 51(9):2595–2610. https://doi.org/10.1016/S1359-6454(03)00058-2

Chen X, **ong L, McDowell DL, Chen Y (2017) Effects of phonons on mobility of dislocations and dislocation arrays. Scripta Mater 137:22–26. https://doi.org/10.1016/j.scriptamat.2017.04.033

Chen X, Li W, Diaz A, Yang L, Chen Y, McDowell DL (2017) Recent progress in the concurrent atomistic-continuum method and its application in phonon transport. MRS Commun 7:785–797. https://doi.org/10.1557/mrc.2017.116

**ong L, Chen Y, Beyerlein IJ, McDowell DL (2021) Multiscale modeling of interface-mediated mechanical, thermal, and mass transport in heterogeneous materials: perspectives and applications. J Mater Res 36:2601–2614. https://doi.org/10.1557/s43578-021-00293-4

Forest S, Mayeur JR, McDowell DL (2019) Micromorphic crystal plasticity. In: Voyiadjis G (eds) Handbook of nonlocal continuum mechanics for materials and structures. Springer, Cham. pp 643–686. https://doi.org/10.1007/978-3-319-58729-5_49

Coleman BD, Gurtin ME (1967) Thermodynamics with ISVs. J. Chem Phys 47:597–613. https://doi.org/10.1063/1.1711937

Coleman BD, Noll W (1963) The thermodynamics of elastic materials with heat conduction and viscosity. Arch Ration Mech Anal 13(1):167–178. https://doi.org/10.1007/BF01262690

Kestin J, Rice JR (1970) Paradoxes in the application of thermo-dynamics to strained solids. In: Stuart EB, Gal Or B, Brainard AJ (eds) A critical review of thermodynamics. Mono-Book Corp., Baltimore, pp 275–298

Chaboche JL (1977) Viscoplastic constitutive equations for the description of cyclic and anisotropic behaviour of metals. Bull, de I’Acad. Polonaise des Sciences, Serie Sc. et Techn., 17th Polish Conf. on Mechanics of Solids. Szczyrk 25:33–41

Germain P, Nguyen QS, Suquet P (1983) Continuum thermodynamics. ASME J Appl Mech 50:1010. https://doi.org/10.1115/1.3167184

Chaboche JL, Roussellier G (1983) On the plastic and viscoplastic constitutive equations-part I: rules developed with internal variable concept. ASME J Pressure Vessel Techn 105:153–158. https://doi.org/10.1115/1.3264257

Chaboche JL, Roussellier G (1983) On the plastic and viscoplastic constitutive equations- part II: application of the internal variables concepts to the 316 Stainless Steel. ASME J Pressure Vessel Techn 105:159–164. https://doi.org/10.1115/1.3264258

Chaboche JL (1983) On the constitutive equations of materials under monotonic or cyclic loadings. La Recherche Aerospatiale 5:31–43

Muschik W (1993) Fundamentals of nonequilibrium thermodynamics. In Muschik W (ed) Non-equilibrium thermodynamics with applications to solids, CISM Courses and Lectures No. 336, International Centre for Mechanical Sciences, ed. W. Mushik, Springer-Verlag, New York, pp 1–63

McDowell DL (2005) ISV Theory. In: Yip S. (ed) Handbook of materials modeling. Springer, Dordrecht. https://doi.org/10.1007/978-1-4020-3286-8_58

Horstemeyer MF, Bammann DJ (2010) Historical review of ISV theory for inelasticity. Int J Plast 26(9):1310–1334. https://doi.org/10.1016/j.ijplas.2010.06.005

McDowell DL (2019) Multiscale modeling of interfaces, dislocations, and dislocation field plasticity. In: S. Mesarovic et al. (eds) Mesoscale models: from micro-physics to macro-interpretation. CISM-Springer, Springer Science Business Media, CISM International Centre for Mechanical Sciences 587, pp 195–297. https://springer.longhoe.net/chapter/10.1007%2F978-3-319-94186-8_5

Li D, Wagoner RH (2021) The nature of yielding and anelasticity in metals. Acta Mater 206:116625. https://doi.org/10.1016/j.actamat.2021.116625

Spearot DE, McDowell DL (2009) Atomistic modeling of grain boundaries and dislocation processes in metallic polycrystalline materials. ASME J Eng Mater Technol 131(4):0412041–0412049. https://doi.org/10.1115/1.3183776

Dewald MP, Curtin WA (2011) Multiscale modeling of dislocation/grain-boundary interactions: III. 60° dislocations im**ing on Σ3, Σ9 and Σ11 tilt boundaries in Al. Modell Simul Mater Sci Eng 19(5):055002. https://doi.org/10.1088/0965-0393/19/5/055002

Xu S, **ong L, Chen Y, McDowell DL (2016) Sequential slip transfer of mixed character dislocations across Σ3 coherent twin boundary in fcc metals: a concurrent atomistic-continuum study. npj Comput Mater 2:15016. https://doi.org/10.1038/npjcompumats.2015.16

Spearot DE, Sangid MD (2014) Insights on slip transmission at grain boundaries from atomistic simulations. Curr Opin Solid State Mater Sci 18(4):188–195. https://doi.org/10.1016/j.cossms.2014.04.001

Li L, Liu L, Shibutani Y (2022) Defect interaction summary between edge dislocations and <112>-axis symmetric tilt grain boundaries in copper on activation barriers and critical stresses. Int J Plast 149:103153. https://doi.org/10.1016/j.ijplas.2021.103153

Su Y, Phan T, **ong L, Kacher J (2023) Multiscale computational and experimental analysis of slip-GB reactions: in situ high-resolution electron backscattered diffraction and concurrent atomistic-continuum simulations. Scripta Mater 232:115500. https://doi.org/10.1016/j.ijplas.2021.103153

Kacher J, Eftink BP, Cui B, Robertson IM (2014) Dislocation interactions with grain boundaries. Curr Opin Solid State Mater Sci 18(4):227–243. https://doi.org/10.1016/j.cossms.2014.05.004

Erdle H, Böhlke T (2023) Analytical investigation of a grain boundary model that accounts for slip system coupling in gradient crystal plasticity frameworks. Proc R Soc A 479:20220737. https://doi.org/10.1098/rspa.2022.0737

Acknowledgement

This effort is conducted in tribute to the legacy of collaborations and contributions made by Hussein Zbib in modeling and understanding multiscale aspects of dislocation plasticity using methods and tools ranging from DDD to crystal plasticity to generalized continua descriptions. Support of the Carter N. Paden, Jr. Distinguished Chair in Metals Processing, is gratefully acknowledged.

Author information

Authors and Affiliations

Contributions

This work is the sole intellectual product of the author.

Corresponding author

Ethics declarations

Conflict of interest

No conflicts of interest exist, and the author declares he has no competing interests.

Ethical approval

Not applicable.

Additional information

Handling Editor: M. Grant Norton.

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

McDowell, D.L. Nonequilibrium statistical thermodynamics of thermally activated dislocation ensembles: part 3—Taylor–Quinney coefficient, size effects and generalized normality. J Mater Sci 59, 5161–5200 (2024). https://doi.org/10.1007/s10853-023-09143-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-023-09143-6