Abstract

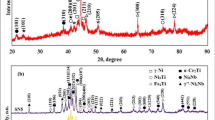

In this study, we introduced a modified cathodic cage plasma deposition (CCPD) system to synthesize a Ti–Nb–C–N-based composite coating on AISI-4340 steel. This composite coating is widely applied in orthopedic joint implants due to its effective bioactivity and wear resistance. In the existing CCPD system, a metallic cathodic cage of a specific material is used to deposit the coating of such material. Thus, it cannot be used to deposit the coating of a composite material. Here, we inserted composite material rings (80% TiO2 + 10% Nb2O5 + 10% graphite) on the lid of the cathodic cage, where the cathodic cage holds these rings and works as a counter electrode for plasma generation. The composite coating is synthesized in nitrogen plasma at various temperatures (300–400 °C) and various hydrogen contents (20, 50, and 80%). It is observed that the hardness of AISI-4340 steel (280 HV0.25) can be increased up to 1430 HV0.25 for coating deposited at 400 °C and 50% hydrogen, which is 5 times higher than the untreated sample. The XRD pattern shows that composite coating consists of TiN, Ti2N, NbN, NbC, and TiO2. The contents of oxide phase TiO2 are reduced by adding hydrogen gas to the processing environment; thus, the nitride-based composite coating can be synthesized. The wear volume is significantly reduced by composite coating, specifically while using higher hydrogen contents and higher temperatures. This study shows that this modified CCPD system can improve the hardness and wear resistance by synthesizing this composite coating. In contrast with conventional techniques, separate metallic targets for each element in composite coating (titanium, niobium, and carbon targets) are not required, simple equipment, rough vacuum level are required, and high-processing efficiency are advantages of this system.

Graphical abstract

Similar content being viewed by others

Data availability

All the data discussed in this work are presented in graphical form and therefore immediately available.

References

de Campos LDAP, de Almeida LS, da Silva BP, Danelon MR, Aoki IV, Manfrinato MD, Rossino LS (2020) Evaluation of nitriding, nitrocarburizing, organosilicon interlayer, diamond-like carbon film and duplex plasma treatment in the wear and corrosion resistance of AISI 4340 Steel. J Mater Eng Perform 29(12):8107–8121

Anazawa RM, Abdalla AJ, Hashimoto TM, Pereira MS (2014) Estudo comparativo das propriedades mecânicas em aços 4340 e 300M submetidos a tratamentos térmicos isotérmicos e intercríticos. Revista Brasileira de Aplicações de Vácuo 31(1–2):32–37

Kovacı H, Baran Ö, Yetim AF, Bozkurt YB, Kara L, Çelik A (2018) The friction and wear performance of DLC coatings deposited on plasma nitrided AISI 4140 steel by magnetron sputtering under air and vacuum conditions. Surf Coat Technol 349:969–979

Hatakeyama M, Masahashi N, Michiyama Y, Inoue H, Hanada S (2021) Wear resistance of surface-modified TiNbSn alloy. J Mater Sci 56(25):14333–14347. https://doi.org/10.1007/s10853-021-06213-5

Li J, Tao X, Wu W, **e G, Yang Y, Zhou X, Zhang S (2023) Effect of arc current on the microstructure, tribological and corrosion performances of AISI 420 martensitic stainless steel treated by arc discharge plasma nitriding. J Mater Sci 58:2294–2309. https://doi.org/10.1007/s10853-023-08161-8

Amanov A (2019) Surface engineering-controlled tribological behavior and adhesion strength of Ni-Cr coating sprayed onto carburized AISI 4340 steel substrate. Surf Coat Technol 370:144–156

de Mendonça Ferreira ST, Bacco ALK, do Nascimento EM, Lepienski CM (2021) Mechanical characterization and micro-wear of FeB-Fe2B layers on boriding AISI D2 and AISI 4340 steels. Mater Sci Appl 12(7):330–344

Pereloma EV, Conn AW, Reynoldson RW (2001) Comparison of ferritic nitrocarburising technologies. Surf Coat Technol 145(1–3):44–50

Ginting A, Skein R, Cuaca D, Masyithah ZJM (2018) The characteristics of CVD-and PVD-coated carbide tools in hard turning of AISI 4340. Measurement 129:548–557

Qi F, Leng YX, Huang N, Bai B, Zhang PC (2007) Surface modification of 17–4PH stainless steel by DC plasma nitriding and titanium nitride film duplex treatment. Nucl Instrum Methods Phys Res Sect B 257(1–2):416–419

Dalibon EL, Moscatelli M, Simison S, Escalada L, Cabo A, Lasorsa C, Brühl SP (2015) Corrosion behaviour of a SiOxNy coated and nitrided PH stainless steel. Proced Mater Sci 8:29–38

Yan MF, Zhu YD, Zhang CS, Zhang YX, Wang YXY, Yang L (2015) Microstructure and mechanical properties of copper–titanium–nitrogen multiphase layers produced by a duplex treatment on C17200 copper–beryllium alloy. Mater Des 84:10–17

Dalibón EL, Guitar MA, Trava-Airoldi V, Mücklich F, Brühl SP (2015) Plasma nitriding and DLC coatings for corrosion protection of precipitation hardening stainless steel. Adv Eng Mater 18(5):826–832

Hakami F, Heydarzadeh Sohi M, Rasizadeh Ghani J, Ebrahimi M (2011) Chromizing of plasma nitrided AISI 1045 steel. Thin Solid Films 519:6783–6786

Naeem M, Shafiq M, Zaka-ul-Islam M, Bashir MI, Díaz-Guillén JC, Lopez-Badillo CM, Zakaullah M (2017) Novel duplex cathodic cage plasma nitriding of non-alloyed steel using aluminum and austenite steel cathodic cages. J Alloy Compd 721:307–311

Habibolahzadeh A, Haftlang F (2018) Duplex surface treatment of AISI 1045 steel via pack boriding and plasma nitriding: characterization and tribological studies. J Tribol 140(2):021602

Selvabharathi R, Muralikannan R (2018) Influence of shot peening and plasma ion nitriding on tensile strength of 2205 duplex stainless steel using A-PAW. Mater Sci Eng A 709:232–240

Miao B, Song L, Chai Y, Wei K, Hu J (2017) The effect of sand blasting pretreatment on plasma nitriding. Vacuum 136:46–50

Madanipour H, Soltanieh M, Nayebpashaee N (2013) Investigation of the formation of Al, Fe, N intermetallic phases during Al pack cementation followed by plasma nitriding on plain carbon steel. Mater Des 51:43–50

Nakata K, Yamauchi W, Akamatsu K, Ushio M (2003) Plasma nitriding behavior of low carbon binary alloy steels. Surf Coat Technol 174:1206–1210

Haftlang F, Habibolahzadeh A, Sohi MH (2015) Improving electrochemical properties of AISI 1045 steels by duplexsurface treatment of plasma nitriding and aluminizing. Appl Surf Sci 329:240–247

Ashrafizadeh F (2003) Influence of plasma and gas nitriding on fatigue resistance of plain carbon (Ck45) steel. Surf Coat Technol 174:1196–1200

Zhou Y, Yang Y, Yang J, Hao F, Li D, Ren X, Yang Q (2012) Effect of Ti additive on (Cr, Fe) 7C3 carbide in arc surfacing layer and its refined mechanism. Appl Surf Sci 258(17):6653–6659

Imurai S, Thanachayanont C, Pearce JTH, Tsuda K, Chairuangsri T (2015) Effects of W on microstructure of as-cast 28 wt% Cr–2.6 wt% C–(0–10) wt.% W irons. Mater Charact 99:52–60

Bedolla-Jacuinde A, Guerra FV, Mejía I, Zuno-Silva J, Rainforth M (2015) Abrasive wear of V–Nb–Ti alloyed high-chromium white irons. Wear 332:1006–1011

Zhi X, **ng J, Fu H, Gao Y (2008) Effect of titanium on the as-cast microstructure of hypereutectic high chromium cast iron. Mater Charact 59(9):1221–1226

Zhi X, **ng J, Fu H, **ao B (2008) Effect of niobium on the as-cast microstructure of hypereutectic high chromium cast iron. Mater Lett 62(6–7):857–860

Zhang M, Li M, Wang S, Chi J, Ren L, Fang M, Zhou C (2020) Enhanced wear resistance and new insight into microstructure evolution of in-situ (Ti, Nb) C reinforced 316 L stainless steel matrix prepared via laser cladding. Opt Lasers Eng 128:106043

Zhang M, Li M, Chi J, Wang S, Fang M, Zhou C, Liang B, Xue J (2020) In-situ (Ti, Nb) C reinforced Ni-based coatings: new insights into microstructure evolution, enhanced phase configuration behavior and tribological properties. Ceram Int 46(9):14161–14172

Grigoriev S, Vereschaka A, Milovich F, Tabakov V, Sitnikov N, Andreev N, Bublikov J, Sotova C (2021) Investigation of the properties of Ti-TiN-(Ti, Al, Nb, Zr) N composite coating and its efficiency in increasing wear resistance of metal cutting tools. Surf Coat Technol 421:127432

Zhao Y, Chen L, Sun J, Wu W, Yu T (2022) Microstructure evolution and wear resistance of in-situ synthesized (Ti, Nb) C ceramic reinforced Ni204 composite coatings. Ceram Int 48(12):17518–17528

Li CX, Georges J, Li X-Y (2002) Active screen plasma nitriding of austenitic stainless steel. Surf Eng 18(6):453–457

Gallo SC, Dong H (2009) On the fundamental mechanisms of active screen plasma nitriding. Vacuum 84(2):321–325

Saeed A, Khan A, Jan F, Abrar M, Khalid M, Zakaullah M (2013) Validity of “sputtering and re-condensation” model in active screen cage plasma nitriding process. Appl Surf Sci 273:173–178

Fraczek T, Ogorek M, Skuza Z, Prusak R (2020) Mechanism of ion nitriding of 316L austenitic steel by active screen method in a hydrogen-nitrogen atmosphere. Int J Adv Manuf Technol 109(5):1357–1368

Dong Y, Li X, Tian L, Bell T, Sammons RL, Dong H (2011) Towards long-lasting antibacterial stainless steel surfaces by combining double glow plasma silvering with active screen plasma nitriding. Acta Biomater 7(1):447–457

Nascimento IO, Naeem M, Freitas RS, Nascimento RM, Viana BC, Sousa RRM, Feitor MC, Iqbal J, Costa THC (2022) Comparative study of structural and stoichiometric properties of titanium nitride films deposited by cathodic cage plasma deposition and magnetron sputtering. Euro Phys J Plus 137(3):319

Zaka-ul-Islam M, Naeem M, Shafiq M, Sitara A-R, Zakaullah M (2017) Active screen cage pulsed dc discharge for implanting copper in polytetrafluoroethylene (PTFE). Mater Res Express 4(7):075304

Junior WN, Naeem M, Costa THC, Díaz-Guillén JC, Díaz-Guillén MR, Iqbal J, Jelani M, Sousa RRM (2021) Surface modification of AISI-304 steel by ZnO synthesis using cathodic cage plasma deposition. Mater Res Express 8(9):096403

Naeem M, Torres AVR, Serra PLC, Monção RM, Junior CAA, Rossino LS, Costa THC, Costa C, Iqbal J, Sousa RRM (2022) Combined plasma treatment of AISI-1045 steel by hastelloy deposition and plasma nitriding. J Build Eng 47:103882

Kovács D, Dobránszky J, Fodor T, Takáts V, Bonyár A (2020) Investigation of the ASPN process of low alloy steel by using Ni or Cr coated active screens. Surf Coat Technol 394:125638

Yazdani A, Soltanieh M, Aghajani H (2015) Active screen plasma nitriding of Al using an iron cage: characterization and evaluation. Vacuum 122:127–134

Naeem M, Fortaleza VC, Serra PLC, Lima CL, Costa THC, Sousa RRM, Díaz-Guillén JC, Mancillas-Salas S, Iqbal J (2021) Synthesis of molybdenum oxide on AISI-316 steel using cathodic cage plasma deposition at cathodic and floating potential. Surf Coat Technol 406:126650

Nishimoto A, Nii H, Akamatsu K, Nagatsuka K, Narita R (2011) Effect of gas pressure on active screen plasma nitriding response. J ASTM Int 8(3):1–7

Ahangarani S, Sabour A, Mahboubi F, Shahrabi T (2009) The influence of active screen plasma nitriding parameters on corrosion behavior of a low-alloy steel. J Alloy Compd 484(1):222–229

Naeem M, Shafiq M, Zaka-ul-Islam M, Nawaz N, Díaz-Guillén J, Zakaullah M (2016) Effect of cathodic cage size on plasma nitriding of AISI 304 steel. Mater Lett 181:78–81

De Sousa RRM, De Araújo FO, Da Costa JAP, Dumelow T, De Oliveira RS, Alves C Jr (2009) Nitriding in cathodic cage of stainless steel AISI 316: Influence of sample position. Vacuum 83(11):1402–1405

De Sousa R, De Araújo F, Gontijo L, da Costa J, Alves C (2012) Cathodic cage plasma nitriding (CCPN) of austenitic stainless steel (AISI 316): influence of the different ratios of the (N2/H2) on the nitrided layers properties. Vacuum 86(12):2048–2053

Sun Y, Bell T (2003) Low temperature plasma nitriding characteristics of precipitation hardening stainless steel. Surf Eng 19(5):331–336

Taherkhani F, Taherkhani A (2010) Surface characterization of through cage plasma nitriding on the surface properties of low alloy steel. Sci Iran 17(4):253–263

Shivaee HA, Hosseini HRM, Lotfabad EM, Roostaie S (2010) Study of nanocrystallization in FINEMET alloy by active screen plasma nitriding. J Alloy Compd 491(1):487–494

Barbosa MGC, Viana BC, Santos FEP, Fernandes F, Feitor MC, Costa THC, Naeem M, Sousa RRM (2021) Surface modification of tool steel by cathodic cage TiN deposition. Surf Eng 37(3):334–342

Libório MS, Praxedes GB, Lima LLF, Nascimento IG, Sousa RRM, Naeem M, Costa TH, Alves SM, Iqbal J (2020) Surface modification of M2 steel by combination of cathodic cage plasma deposition and magnetron sputtered MoS2-TiN multilayer coatings. Surf Coat Technol 384:125327

ASTM G99–17 Standard test method for wear testing with a pin-on-disk apparatus. ASTM International

Naeem M, Iqbal J, Abrar M, Khan KH, Díaz-Guillén JC, Lopez-Badillo CM, Shafiq M, Zaka-ul-Islam M, Zakaullah M (2018) The effect of argon admixing on nitriding of plain carbon steel in N2 and N2–H2 plasma. Surf Coat Technol 350:48–56

Balakrishnan G, Sundari ST, Ramaseshan R, Thirumurugesan R, Mohandas E, Sastikumar D, Kuppusami P, Kim TG, Song JI (2013) Effect of substrate temperature on microstructure and optical properties of nanocrystalline alumina thin films. Ceram Int 39(8):9017–9023

Huang D, He W, Cao X, Jiao Y (2020) Investigations in anti-impact performance of tin coatings prepared by filtered cathodic vacuum arc method under different substrate temperatures. Coatings 10(9):840

Nishimoto A, Fukube T, Tanaka T (2016) Effect of surface deposits on nitriding layer formation of active screen plasma nitriding. Mater Trans 57(10):1811–1815

Brading HJ, Morton PH, Bell T, Earwaker LG (1992) Plasma nitriding with nitrogen, hydrogen, and argon gas mixtures: structure and composition of coatings on titanium. Surf Eng 8(3):206–212

Naeem M, Hussain Khan K, Shahid M, Iqbal J, Shafiq M, Zaka-ul-Islam M, Zakaullah M (2018) Non-intrusive measurement of electron, vibrational, rotational temperatures and active species concentration in N2–H2 cathodic cage plasma. Surf Coat Technol 344:233–243

Sirin SY, Sirin K, Kaluc E (2008) Effect of the ion nitriding surface hardening process on fatigue behavior of AISI 4340 steel. Mater Charact 59(4):351–358

Sirin SY, Kaluc E (2012) Structural surface characterization of ion nitrided AISI 4340 steel. Mater Des 36:741–747

Díaz-Guillén JC, Vargas-Gutiérrez G, Granda-Gutiérrez EE, Zamarripa-Piña JS, Pérez-Aguilar SI, Candelas-Ramírez J, Álvarez-Contreras L (2013) Surface properties of Fe4N compounds layer on AISI 4340 steel modified by pulsed plasma nitriding. J Mater Sci Technol 29(3):287–290

Asadi ZS, Mahboubi F (2012) Effect of component’s geometry on the plasma nitriding behavior of AISI 4340 steel. Mater Des 34:516–521

Jebaraj JJM, Morrison DJ, McLaughlin JB, Suni II (2014) Effect of nitriding on the hydrogen diffusion coefficient through AISI 4340. J Electrochem Soc 161(5):C261

Aizawa, T, Yoshihara SI, (2018) Homogeneous and heterogeneous micro-structuring of austenitic stainless steels by the low temperature plasma nitriding. In: IOP conference series: materials science and engineering. vol 372, p 012049

Murali AP, Alphonse M, Ganesan D, Salunkhe S, Hussein HMAM (2023) Sliding wear behaviour of salt bath nitrided 316LN austenitic stainless steel. Appl Surf Sci Adv 15:100401

Guzman P, Caballero JL, Orozco-Hernández G, Aperador W, Caicedo JC (2018) Tribocorrosion behavior of niobium-based thin films for biomedical applications. Triboln Ind 40(4):624

Chen W, Zheng J, Meng X, Kwon S, Zhang S (2015) Investigation on microstructures and mechanical properties of AlCrN coatings deposited on the surface of plasma nitrocarburized cool-work tool steels. Vacuum 121:194–201

Sugumaran AA, Shukla K, Khan I, Ehiasarian AP, Hovsepian PE (2021) Dry sliding wear mechanisms of HIPIMS plasma nitrided CoCrMo alloy for medical implant applications. Vacuum 185:109994

Peng P, Schiappacasse C, Zhou N, Addy M, Cheng Y, Zhang Y, Ding K, Wang Y, Chen P, Ruan R (2019) Sustainable non-thermal plasma-assisted nitrogen fixation—synergistic catalysis. Chemsuschem 12(16):3702–3712

Haftlang F, Habibolahzadeh A, Sohi MH (2014) Comparative tribological studies of duplex surface treated AISI 1045 steels fabricated by combinations of plasma nitriding and aluminizing. Mater Des 60:580–586

Naeem M, Raza HA, Shafiq M, Zaka-ul-Islam M, Iqbal J, Díaz-Guilléne JC, Zakaullah M (2017) Effect of pulsed duty cycle control on tribological and corrosion properties of AISI-316 in cathodic cage plasma nitriding. Mat Res Express 4:116507

Acknowledgements

This study was financed in part by the “Coordenação de Aperfeiçoamento de Pessoal de Nível Superior (CAPES), Brazil” Finance Code 001. Dr. M. Naeem is thankful to the higher education commission (HEC) Pakistan for partial support in this research work through National Research Project for Universities (NRPU) project number 14417 at WUAJ&K.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

All authors declare that they have no conflict of interest.

Ethical approval

Not applicable.

Additional information

Handling Editor: Maude Jimenez.

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Neto, J.F.M., Naeem, M., Costa, T.H.C. et al. Synthesis of Ti–Nb–C–N based composite coating on AISI-4340 steel by modified cathodic cage plasma deposition. J Mater Sci 58, 7182–7194 (2023). https://doi.org/10.1007/s10853-023-08494-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-023-08494-4